Agriculture waste 1000kg/h wood pellet making/briquette machinery equipment/africa firewood briquette making machine price

-

Supplier: Zhengzhou Sinatural Machinery Equipment Co., Ltd. -

Region: Henan, China -

Contact: Mr. Baoshan Guan -

Price: $14000.00 /set -

Min. Order: 1 set

| Condition: | New; | After-sales Service Provided: | Online support; |

| Place of Origin: | Henan China; | Voltage: | 380V 50HZ; |

| materail length(mm): | 2-50; | Application: | Biomass Fuel; |

| Supply Ability: | 100 Set/Sets per Month agriculture waste 1000kg/h wood pellet making machine(ce) with g; | briquette moisture: | ≤15%; |

| briquette size(mm): | 32*32; | material moisture: | 20-40%; |

| Brand Name: | Sinatural; | Applicable Industries: | Manufacturing Plant; |

| briquette density(g/cm3): | 0.8-1.2; | Production Capacity: | 800-1500kg/h; |

| model number: | 36 hole; | After-sales Service Provided: | Engineers available to service machinery overseas; |

| Weight: | 2200kg; | Dimension(L*W*H): | 2400*1300*1780; |

| Port: | xingang or shanghai; | Packaging Detail: | in container or as per customer requirement; |

| Warranty: | One Year; | dimention(mm): | 2400*1300*1780; |

| Certification: | CE/ISO9001; | Heating power(Kw): | 4; |

| Payment Terms: | L/C,T/T,Western Union,MoneyGram; | Features: | Energy Saving; |

The 9HYK series of flat ring mold biomass fuel forming machines produced by our company have completely changed the disadvantages of uneven force of the original ring machine main shaft and inconvenient disassembly and maintenance of the mold. The new compression mode is adopted, and the vertical ring mold structure is flat. The ring mode production uses the principle of self-rotating centrifugal force to evenly distribute the raw materials into all the forming molds, avoiding the boring phenomenon caused by the excessive concentration of local materials, and greatly reducing the unit energy consumption.

Technical data

| Model | 9HYK—1000 | 9HYK—1500 |

| power(Kw) | 37 | 55 |

| capacity(kg/h) | 800--1500 | 1200--2000 |

| model number | 36 hole | 45 hole |

| briquette density(g/cm3) | 0.8—1.2 | 0.8—1.2 |

| Heating power(Kw) | 4 | 4 |

| material moisture | 20—40% | 20—40% |

| materail length(mm) | 2—50 | 2—50 |

| briquette moisture | ≤15% | ≤15% |

| dimention(mm) | 2400×1300×1780 | 3000×1500×1780 |

| weight(t/set) | 2.2 | 2.2 |

| equipped with | feeding conveyor, discharging conveyor,control cabinet | |

model detail

material and briquet

advantage

1. Stainless steel die, with heat treatment process, longer service time of moldsfor this biomass briquette machine.

2. Adopt American CPM technology, with reasonable design, saving electricity consumption 30%.

3. Pressing density is adjustable between 0.8g/cm3 and 1.4 g/cm3, by changing space between roller and molds.

4. Advanced heat releasing system. the biomass briquette machine adopts multi-channel, multi-angle cooling mode. ensure straw biomass briquette machine can run 24 hours without shut down.

5. Power-off protection—automatic power-off when facing overload or failure.

6. No Additives and adhesives needed during whole process.

7. we supply conveyor belt for feeding and discharging, dust collector and electrical control system for this biomass briquette machine.

8. Adopts imported NSK, NTN, SKF bearings, the motor is Siemens brand or Chinese famous SH brand.

9. We also supply complete straw or other biomass briquette machine line.

10. It is very efficient of 9YK biomass briqeutte machine, which takes use of flat die design, to obtain a bettler press and lower enegy cnsumption. As to the die system, we develop a " plate and little mold system", which means there are little molds on the plate, and roller moves on the little molds. In this case, you only need to replace the little mold when it is broken. it only takes two man 15 mintures to replace the die, very efficient.

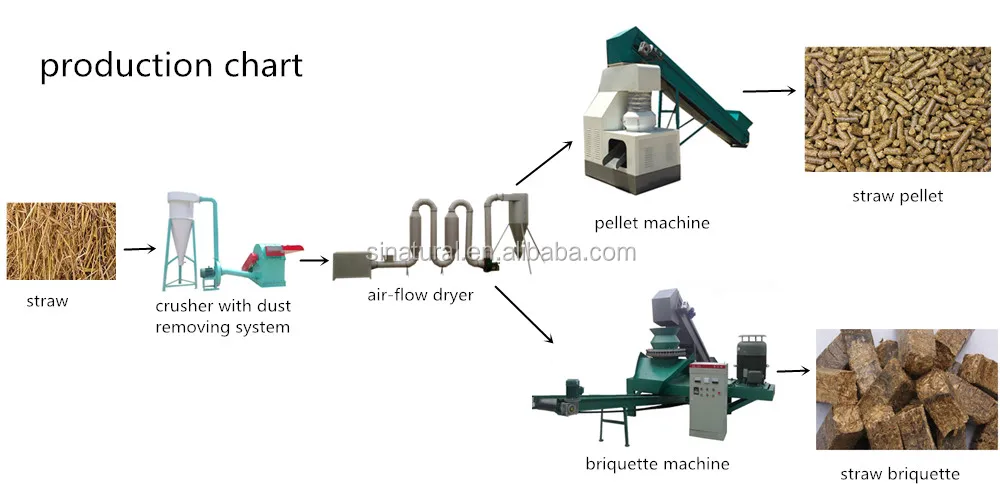

production chart

1. What's the delivery time?

We will deliver the product in 7-15 days after receiving the deposit.

2. What's your payment terms?

We can accept various payment terms if it is convenient for you.

3. what's your MAQ?

Our MAQ is 1 piece.

4. What is your warranty?

12 months except the spare parts.And the main part lifelong time guarantee.

5. Will you send engineers to install the plant?

Of course yes,but at an extra cost will be paid by customers.

-

Cheap briquette forming charcoal briquette machine honeycomb punching machine

-

Bassage Extruder Machine

-

Sawdust Briquette Making Machine

-

Stamping Stick Machine

-

Biomass Briquette Machine

-

Peanut Shells Extruder Machine

-

Sawdust Extruder Machine For Sale

-

Zhuozhilan Factory Coconut BBQ Charcoal Coal Production Line Fast Delivery Various Shapes Charcoal

-

32hp diesel engine biomass briquette machine carbon bagasse wood coal sawdust briquette extrusion molding press making machine

-

Biomass powder sawdust briquetting machine