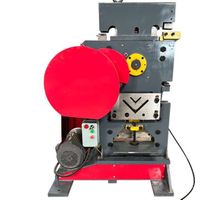

Anhui Haili CNC sheet cutting machine adopts hydraulic cutting machine

-

Supplier: Anhui Haili Machine Tool Manufacturing Co., Ltd. -

Region: Anhui, China -

Contact: Mr cao jun -

Price: $4000.00 / 1 - 1 sets

$3000.00 / >=2 sets -

Min. Order: 1 set

| Processing: | yes | Showroom location: | Canada |

| Supply capacity: | 50 sets per month | Shears color: | blue, white or other |

| place of origin; place of origin: | Anhui, China | After-sales service provided: | Engineers available to service machinery overseas |

| port: | FOB Shanghai Port | After warranty service: | Video Technical Support |

| Motor power (kW): | 4.5 | Local service location: | Kyrgyzstan |

| CNC or not: | CNC | Main selling points: | easy to operate |

| Packaging Details: | Wooden case, plastic cover packing or provide metal plate hydraulic gate QC12K 6x3200mm metal plate hydraulic gate shearing machine on request | Applicable industries: | manufacturing plant |

| Warranty: | 1 year, provide technical services for life | State of health: | new |

| Nominal force (kN): | 4 | Voltage: | 380V/60HZ /3P (according to local voltage) |

| Cutting angle: | 0.5-4° | Voltage: | 380/220V or according to your |

| brand: | Li Wei/Hui Rui | Certification: | International Standards and International Standards |

| Shearing machine back gauge: | 20-800mm | payment terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Energy source: | hydraulic | Machine stroke: | 3-18 times per minute. |

| Dimensions (L*W*H): | depends on details | Cut length: | 2500-6000mm |

| Cutting thickness: | 4-40mm | main power: | 4-75kw |

| Weight (ton): | 3000 |

product name:

Anhui Haili QC12Y, QC12K, QC11Y, QC11K CNC hydraulic shearing machine, shearing machine price, shearing machine

Best-selling machine (shearing machine)

|

1. |

All kinds of best-selling models for you to choose |

|

2. |

MOQ |

|

3. |

fast delivery time |

|

4. |

Target price |

describe:

|

color |

any color is available |

|

trademark |

Best Selling Shearing Machine Customized Logo |

|

MOQ |

MOQ, 1 set best selling shearing machine |

|

delivery time |

(1) 30-60 days – if you want to customize your request (2)25 days – for our standard |

|

Accept OEM |

yes |

|

provide certification |

yes |

|

CNC system |

delete. Easton... |

|

packaging details |

20GP , 40GP , 20 OT or LCL |

|

production capacity |

500 sets/set best-selling shearing machine per month |

|

expiration of pay |

L/C, T/T, D/A, Western Union, MONEY GRAM |

company information

- Shearing machine

- Shearing machine

Product Description

Standard equipment (100% physical shooting)

Our qc11 series and qc12 series metal cutting machine tools adopt fully welded structure, the picture shows qc12 series

Shear table with ball rollers and material support for easy maneuvering and maneuvering (shears)

Standard MD11 CNC system, we also have other CNC systems to choose from, such as imported DELEM CNC system (made in Holland) and domestic ESTUN CNC system (made in Nanjing), different CNC systems have different axes and progress, functions, etc. It mainly depends on customer's requirement.

Backgauge series, exquisite appearance (shearing machine)

This is to adjust the blade clearance (shears)

Haililiwei brand shearing machine performance:

1. Product appearance and structure of hydraulic shearing machine

1). Using UG analysis method, through computer-aided optimization design

2). The fuselage adopts the whole plate welding structure, which has good strength, rigidity and impact resistance

3). The overall frame adopts sand blasting and derusting method, spraying anti-rust paint

2. Features of hydraulic shearing machine

1). The working surface is equipped with a sub-tool holder, which is easy to track and trim the blade

2). The working surface is equipped with a feeding roller, which is easy to operate

3). The blade gap adjustment adopts stepless adjustment to meet the cutting needs of different thicknesses and materials

4). Rectangular blade, four cutting edges can be used for cutting, which can prolong the life of the blade

5). Adjusting the cutting stroke can improve work efficiency and realize the cutting function

6). The cutting frequency is counted by itself, which can reduce some tedious inventory work

3. Hydraulic system

1). Advanced integrated hydraulic system reduces pipeline installation and ensures high reliability and safety of machine operation

2). Pressing mechanism: installed on the back plate in front of the machine frame, feed and pressurize through several material cylinders, and the pressure material head will drop after overcoming the tension of the tension spring and the pressure plate. After the cutting is completed, it is reset by means of torsion spring tension. The size of the pressing force increases with the increase of the thickness of the shear plate

4. Electrical control system

1). Using international standard electrical components and materials, safe and reliable, long service life

2). The machine adopts 50 Hz, 380 volt three-phase four-wire power supply. Machine motor three-phase 380v, single-phase 220v running lights. The control transformer adopts two-phase 380v. The control transformer outputs 220v for the control circuit, of which 24v is supplied to the electromagnetic reversing valve. 6.3 V power supply for light use.

3). The electrical box of the machine tool is located on the left side of the machine tool. Except for the foot switch, the operating parts of the machine are all concentrated in front of the machine button, and the functions of each operating program component are composed of the Peugeot logo above the image

5. Block material front and rear hydraulic shearing machine

1). Before the gear: placed on the table, there are indicating digital scales, adjust the movable block to reach the required gear value. When cutting thin plates, it is convenient to cut before use.

2). Block: Installed on the tool holder, swing up and down with the upper tool holder, and adjusted by the rear 0.55KW motor, after the transmission of the screw drive gear, press the "+" and "" to adjust the pressure -" to the block The adjustment of the board forward or backward, the digital display size (position) cannot reach the required adjustment value when the motor is adjusted, and the winch wheel can be manually adjusted to ensure the required adjustment value. The following adjustment is convenient and reliable. When the length of the cut sheet is greater than the maximum distance of the baffle, the baffle can be opened to the last position, and the baffle can be lifted to cut the sheet arbitrarily.

Packaging and Shipping

Shearing machine loading operation

QC12 series shearing machine (white) ready to ship to loading port, usually Shanghai, Guangzhou

our service

Advantage:

|

competitive price |

It can fit your budget and best-selling business well. |

|

Accept OEM |

We can produce any design you request. |

|

best service |

We treat customers as friends. |

|

best quality |

We have a strict quality control system. Enjoy a good reputation in the market. |

|

fast delivery |

We get a big discount from the forwarder (long-term contract). |

Our innovations::

|

Quality & Service: At Haili World, our number one priority is always to provide our customers with quality products and excellent customer service. |

|

Fast lead times: We are committed to providing the fastest turnaround time possible and work very hard to ensure all your deadlines are met |

|

Unbeatable Prices: We are constantly working to find ways to reduce production costs and pass the savings on to you! |

|

Brand Awareness: The goal of any strong brand is to achieve a level of awareness that instills ideas of quality and value in all potential customers. |

|

Special Offers: To maintain our competitive edge, we continually offer special offers on our best-selling press brakes, forging equipment merchandise and design services. Contact our terms of sale to find out how we can help you save a lot of money. |

FAQ

Order Guide:

See below for more information on placing an order

|

1. Inquiry - Professional quotation. |

|

2. Confirm the price, delivery date, model, payment terms, etc. |

|

3. Haili factory sales send proforma invoice with 100% stamp. |

|

4. Customer pays the deposit and sends us the bank receipt. |

|

5.Initial Production Stage-Inform the customer that we have received the payment and will make it according to your requirements or our standards, we will inform us that we will arrange production and inform the estimated time. |

|

6. Intermediate Production - Send photos to show the production line where you can see your product. Double-check the estimated delivery time. |

|

7. End Production-Product photos for mass production will be sent to you for approval. You can also arrange third-party inspections. |

|

8. Customers pay the balance and we ship the goods. Payment terms are also acceptable - Balance against B/L Copy Or L/C payment Term. Notify the tracking number and check the status of the customer. |

|

9. After you receive the goods and are satisfied, you can say "done". |

|

10. Feedback quality, service, market feedback and suggestions to Haili factory. And we can do better. |

Why choose us?

- a famous Chinese trademark

- National inspection-free products

-.CE, CQC, SGS, etc.

-.A+ grade service provider

-.Professional over 11 years in manufacturing and trading

-. Actual mechanical pictures

- Feasible solution

- Technology driven products

- Affordable and cost-effective

- Professional and experienced staff

- customer satisfaction

quality

"Achieving and maintaining excellence in quality and service, and striving to

Continuous improvement to ensure total customer satisfaction

competitive price"

All products we can provide:

* WC67K CNC bending machine

* WC67Y hydraulic bending bending machine

* QC12K CNC Shearing Machine

* QC12Y hydraulic shearing machine

* QC11K CNC Shearing Machine

* W11S hydraulic upper roll universal plate rolling machine

* W11 symmetrical plate rolling machine - three rolls

* 23Open Inclined Press / J21S Fixed Table Deep Throat Press

* HRK series metal V-shaped slotting machine

* HCS-I/HCS-11 series hydraulic slotting machine

Dear Customer,

Hi!

We are machine tool manufacturer and exporter with 2 factories, 4 production lines, 7 years Alibaba gold supplier, 11 years international trade, 150 employees.

We work with various dealers, distributors, manufacturers andhopeYou could be the next to visit both of our facilities!

-

New high productivity metal and steel manufacturing plant construction engineering steel processing small punching and shearing machine

-

Chinese manufacturer QA32-8B angle iron cutting machine

-

APEC hydraulic punching die - round hole / oval hole punching

-

Q35y hydraulic sheet metal steelworker shear punching machine

-

Custom Top Punch Die

-

Hydraulic combined punching and shearing machine for sale ironworking machine combined punching and shearing machine

-

Professional hydraulic combined sheet metal working machine

-

APEC small hydraulic ironworking machine punching plate shear multi-function

-

Small hydraulic iron punching machine mechanical punching and shearing machine

-

Factory inventory Q35Y series steel ironwork hydraulic steel punching and shearing machine steel punching and shearing machine