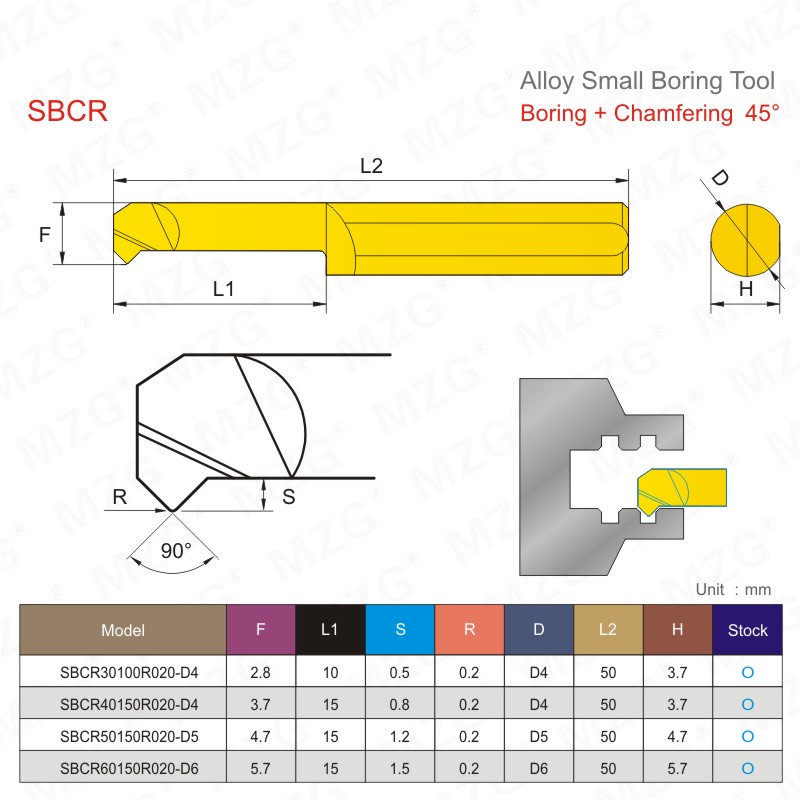

Maifix CNC carbide micro internal groove turning tool SBCR micro boring tool holder

-

Supplier: Dongguan Ming Ze Hardware Machinery Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Eva Lau -

Price: $5.30 / 1 - 99 pieces

$4.60 / 100 - 199 pieces

$3.50 / >=200 pieces -

Min. Order: 1 piece

| Applicable materials: | Steel, stainless steel, aluminum | Material: | Stainless steel |

| Bolt spacing: | Thread M2 or above | Customization support: | Processing |

| delivery time: | 7-10 days | Package preview: | |

| payment terms: | L/C, Western Union, D/A, T/T | Place of origin: | Guangdong |

| Supply capacity: | 20,000 pieces per month | port: | Shenzhen or Guangzhou |

| Minimum working diameter: | 1.5 mm | transportation: | China Post, EUB, DHL, FEDEX, UPS... |

| advantage: | sharp cutting edge | application: | milling machine |

| length: | 40-50mm | brand: | wheat repair |

| control method: | CNC system | Packaging details: | Each piece is packed in random color plastic box and then put into carton |

| type: | Boring tool | accurate: | High accuracy |

| Warranty: | not any | diameter: | 1-8mm |

main feature

1) When using this tool for the first time, try cutting at 50% of the feed rate in the figure above. After the cutting situation is stable, increase the cutting speed and feed rate one by one.

2) Please use a chuck set with high precision, high rigidity and good dynamic balance. The tool runout accuracy is better than 0.01mm. Please improve it after cutting.

Tungsten steel material

Using American ultra-micron tungsten steel material to improve wear resistance and service life

Cutting edge design

The double-edge design ensures cutting stability and accuracy.

passivation coating

The ultra-precision cutting edge is passivated before coating, and advanced coating technology is used to improve the chip resistance and wear resistance of the tool.

More choices

Various sizes of thread milling cutters, reamers, and drill bits are available to suit different processing needs.

All products undergo strict quality inspection before leaving the factory to ensure the normal operation of production.

-

Factory sale solid carbide boring bar reverse C12M-SCLCR09 for ccmt09

-

BKEA PCD outer round turning tool fine cylindrical boring tool CNC carbide boring bar blade lathe round boring tool

-

High precision boring head kit BT40-NBH2084 milling machine NT MT SK R8 handle

-

High quality CNC rough boring head with indexable double drill matching LBK holder

-

Acckee WC/SP/SO U Indexable Efficiency Carbide Insert Drill

-

DO boring bar head connector adapter

-

OEM Factory Solid Carbide Boring Bar Kit Small Bore CNC Internal Turning Tool

-

Fine boring head set for Younio multi bt40 bt50 micro cnc face mill

-

High precision large diameter pin turning boring tool for fine boring

-

boring grass

Other Products

-

$6.00 - $15.00 / piece

$6.00 - $15.00 / piece