High Efficiency Horizontal H-beam Automatic Welding Machine

-

Supplier: Wuxi Zhouxiang Complete Set Of Welding Equipment Co., Ltd. -

Region: Jiangsu, China -

Contact: Mr George Xu -

Price: $90000.00 /set -

Min. Order: 1 set

| Web height: | 300-1500mm; | Payment Terms: | L/C,T/T; |

| After-sales Service Provided: | Online support,Field installation, commissioning and training,Video technical support; | Supply Ability: | 10 Set/Sets per Month; |

| Web thickness: | 4-16mm; | Place of Origin: | Jiangsu China; |

| Condition: | New; | Name: | High Efficiency Horizontal H-beam Automatic Welding Machine; |

| Applicable Industries: | Manufacturing Plant; | Flange width: | 150-500mm; |

| Application: | Weld H beam; | Packaging Detail: | In wooden case, steel frame, export packing; |

| Warranty: | 1 Year; | Edge angle of reduce section: | ≤8°; |

| Welding speed: | 0.3-1.9m/min; | Flange Thickness: | 5-20mm; |

| Main machine power: | 13.4KW; | Port: | Shanghai or as your request; |

| Brand Name: | Zhouxiang; |

High Efficiency Horizontal H-Beam Automatic Welding Machine

BRIEF INTRODUCTION

H-beam steel horizontal production line is a special welding production line that directly

assembles steel plate into H type steel. Compared with the ordinary H-beam steel vertical

welding production line (T type first,H type after), it has the characteristics of high production

efficiency and low welding deformation, and is especially suitable for the welding production

of light type. The production line consists of assembling machine, front welding machine,

overturning machine, end welding machine and input/output conveyor , can achieve H type

steel group, welding, turning, transportation and other work. H-beam steel horizontal production

line can improve the working efficiency and reduce the operation cost, the efficiency is 1.5 times

that of the ordinary steel and the security is better, it also can adapt to various environments.

| Web height | Web thickness | Welding speed | Flange width | Flange thickness | Work-piece length | Work-piece maximum weight | Main machine power |

| 300-1500mm | 3-12mm | 0.3-1.9m/min | 150-500mm | 5-20mm | 4000-15000mm | 4000kg | 13.4KW |

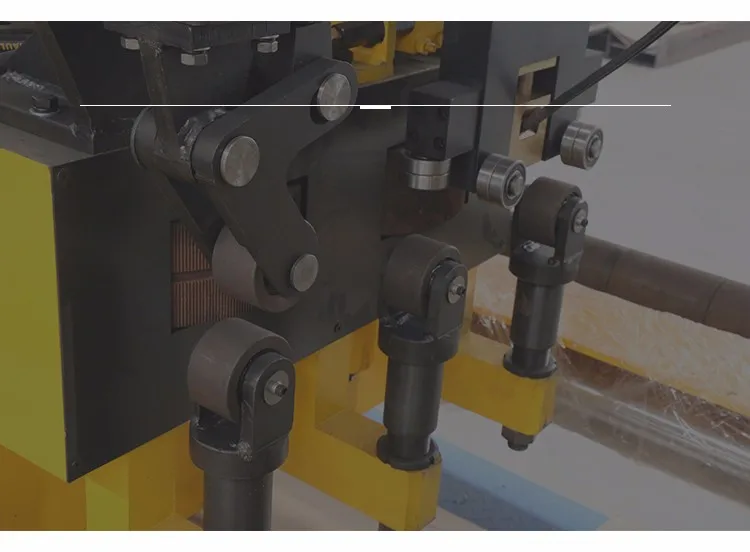

Assembling machine

Input/Output conveyor

Front welding machine

Double 90°overturning machine

End welding machine

Welding

Torch

Magnet

Adsorption

Lincoln

Control Box

Hydraulic

Pump Station

Electrical

Control Cabinet

TECHOLOGY FUNCTION

1.When assemble, just needed to do spot welding of H beam end, then can go into the welding

process, welding machine will re-position the three plate, thus increase assemble speed.

2.Work piece is put horizontally (web is horizontal and flange is vertical), and beam will move

during welding, and can weld two seam at the same time to reduce deformation caused by

welding heat.

3.A variety of welding methods,submerged arc welding and gas shielded welding are available.

4.Machine is equipped with Lincoln DC-1000 welders, which used single arc double wire

welding mode, wire diameter is 1.6mm, and welding speed can reach 1200mm/min, the welding

seams are well formed and look beautiful.

5.It is suitable to weld variable cross section H beam ≤8°.

6.This line is more automatic then traditional ones, so can reduce the labor intensity, and reduce

operator, only need 4~5 operators for normal production.

Wuxi Zhouxiang Complete Set of Welding Equipment Co.,Ltd,founded in 1991,located in Wuxi city, about 100km from Shanghai.We have fixed assets of 150 million yuan,cover an area of 160,000 m2, staff 500 people,including more than 100 engineering and technical personnel.Our company was certified to ISO9001 Quality System Certification firstly in the industry and many products were certified to China Compulsory Certification(CCC).Our products sell well at home and abroad,including Europe,America,Southeast Asia,Middle East and other countries.

Zhouxiang products mainly include CNC flame/plasma cutting machine,H beam light duty production line,H beam heavy duty production line,Horizontal H beam production line,H beam assembly welding straightening integral machine,Corrugated web H beam production line,Box beam production line, Welding manipulator, Rotator, Positioner,Edge milling machine,End face milling machine,Shot blasting machine series,kinds of plate rolling machine,Profile bending machine and welders,fiber laser cutting machine,CO2 laser cutting machine,laser tube cutting machine,Fiber laser cutting robot and Fiber laser welding robot etc.

We have high sincerity to do business with customers all over the world and establish good friendships.

Trade Information | |

Trade Terms: | FOB,CIF,CFR,EXW |

Payment terms: | T/T,L/C |

Payment Condition: | 30% T/T as deposit, 70% balance before delivery |

Delivery Time: | 20-60 days after receiving deposit |

Packing: | In naked, wooden case, steel frame, export packing |

Shipping: | By sea, by air and by express delivery |

FAQ

FAQ

1)Q:Are you a factory or trading company?

A: We are a factory and trading company.

2) Q:Where is your factory located? How can I visit there?

A: Our factory is located in Jiangsu Province(next to Shanghai),China.You can fly to Shanghai airport directly.All our clients, from home or abroad, are warmly welcome to visit us!

3) Q:How does your factory do regarding quality control?

A:"Quality is priority. we always attach great importance to quality controlling from the very beginning to the very end. Our factory has gained ISO, CE certificate.

4) Q:Do you give any discount ?

A:I'll surely try my best to help you get those by the best price and good service at the same time.

5) Q:I would like to ask you if it's possible to have my logo on the product.

A:We hope you know that our company perfectly support customized logo service. But, we also hope you know that it's an extra service,so a little bit extra service fee is needed.

-

CANMAX Manufacturer Construction Engineering High Quality 12m Manual Electric Concrete Pump Spare Parts Mobile Concrete Spreading Arm

-

Prefab Modular House Prefab Prefab House Equipment China 2021

-

China Manufacturer Manufacturing Machine Technology Production Line Guide Rail Telescopic Channel Roll Forming Machine Drawer Slide

-

Earthquake Resistant Precast Concrete House Making Machine, Structural House Equipment

-

160L 280L 350L Tilt Drum Concrete Mixer Mobile Mini Cement Mixer Price

-

Best Selling Roller Shutter Slat Forming Machine / Roller Shutter Door Making Machine

-

Washbasin Pedestal Bathroom Casting Battery Stand

-

modern concrete house machines, fully prefab concrete houses

-

Building materials manufacturing machinery PU sandwich panel machine

-

Price of machine for forming rolls of production line of continuous polyurethane sandwich panels factory customized with ISO9001 / Ce / Sonc

Other Products

-

$40000.00 / set

$40000.00 / set