complete set Tire Retreading Equipment

-

Supplier: Rizhao Melion Industry Co., Ltd. -

Region: Shandong, China -

Contact: Mr Joe Yan -

Price: $50000.00 /set -

Min. Order: 1 set

| Suitable: | Truck tire; | Certification: | CE ISO; |

| Dimension(L*W*H): | 11000*2200*2350; | Weight: | 10,000 kgs; |

| Delivery Detail: | 45 Days after deposit; | Control Type: | Automatic Control; |

| After-sales Service Provided: | Overseas third-party support available; | type: | Tire Retreading Equipment; |

| Heating Method: | Electric Heating; | Port: | Qingdao,Shanghai,Tianjin; |

| Tyre Size: | 15''-22.5''; | Condition: | New; |

| Payment Terms: | T/T; | Heating way: | Electric/Steam; |

| Color: | yellow; | Technology: | Precure/Cold Retread; |

| Power(W): | 120 Kw; | Supply Ability: | 100 Set/Sets per Month tire retreading equipment; |

| Place of Origin: | Shandong China; | Standard Chuck: | 15'',16'',20'',2.5''; |

| Model Number: | ML-YLH-16; | Air Supply: | 0.6-0.8 Mpa; |

| Brand Name: | MELION; | Voltage: | 380v/50Hz; |

| Packaging Detail: | 1*40 Hq container; |

Tire Retreading Equipment

Precure or "Cold" retreading involves vulcanization without a mould at a temperature of between 95 °C and 117 °C. The tyre is put together using a pre-vulcanized Tread Liner Rubber (= new tread) and a non-vulcanized Bonding Gum(Cushion Gum) layer. The bond between the carcass, the bonding gum and the precured tread is created in an autoclave(Curing Chamber). Precure retreading has become fully established in the truck tyres sector since the introduction of radial tyres in the mid-1960s.

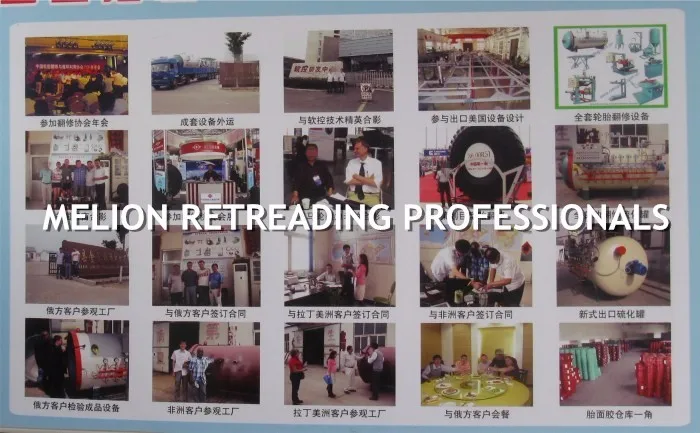

Full set tire retreading equipment

Tire Buffing Machine,Tread Building Machine,Liquid mixing tank,Envelope Spreader,Rims Mounting Machine,Repair Stand Machine,Extruder machine,Dust Collector,Inspection Machine,Tire Pressure Test machine,Curing Chamber with Monorail

Curing Rims with flanges,Extruder Gun,Buffing Wheel,Envelope,Inner Tube,Cushion Gum and Tread Rubber

Curing Chamber

Diffrerent Tire Capacity from 4 tires to 24 tires,for truck ,bus and OTR tires.

Diamter:1500-3500 mm

Heating Method :elctric/oil/steam

In the pre-cured technology, the tread is supplied to the retreading factory cured, with the tread pattern already in place. The treads are supplied in rolls of various lengths (typically 3.5 to 10 meters in length), or as rings that can be stretched onto the casing. In the application of both pre-cured methods, a bonding material, the cushion gum, is applied to the tread or the casing prior to the application of the tread.

Tire Retreading Equipment

Installing & Technical Training

Packing Details : 40 Hq container for one set equipment

Delivery Details : 45 days after deposit payment

As a tire retreading equipment manufacturing supplier who providing Turn-Key Service,Melion provide customers with complete solutions all the time,including professional marketing planing,production line procedure analysis,suitable raw materials supply,free technical training and so on.With its quality products and technical support ,Melion has widely gained excellent reputation from all customers from China and abroad.

A: Yes,we are complete tire retreading solutions supplier who can supply equipment,rubber materials,consumable tools from A to Z.

Q: How long is your delivery time?

A: Generally it is 45 days production time after receive deposit.

Q: Do you provide overseas installation and training service ?

A: Yes, we could send our engineers go to your country for installing and training services.

Q: Can I come to your factory for learning?

A: Welcome for visit any time!

If you have another question, pls feel free to contact us as below:

Sales(at)melionindustry.com

-

Low-price car tire retreading equipment/car tire retreading complete production line

-

Used tire retreading machine/tire retreading machine made in China

-

High quality rubber High quality rubber refill materials

-

Used Tire Retreading Machines Retreading Vehicles Renew Equipment at Low Prices

-

Refurbished machine

-

REENCAUCHADORA LLANTAS Tire Retreading Machine

-

Tire Vulcanizer Repair Electric Retreading Machine

-

Automatic Electric Heating Tyre Repair Machine Hot Tyre Retreading Vulcanizing Machine Customized 220V/380V 1500 KG CN;SHN Q345R

-

Tire Recapping Machines for tyre retreading process

-

Rubber Extruder Gun for Tire retreading machine handheld

Other Products

-

$50000.00 / set

$50000.00 / set -

$50000.00 / set

$50000.00 / set -

$1000.00 / set

$1000.00 / set -

$800.00 / set

$800.00 / set -

$9000.00 / set

$9000.00 / set