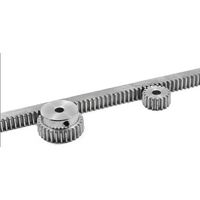

Black Oxidation Steel Iron Casting Large Spur Gear

-

Supplier: Rabily (Kunshan) Manufacturing Co., Ltd. -

Region: Jiangsu, China -

Contact: Mr. Tony Xu -

Price: $130.00 /piece -

Min. Order: 1 piece

| Keyword: | Black Oxidation Steel Iron Casting Large Spur Gear; | Shape: | Cylindrical Gear; |

| MOQ: | 1 Piece available as sample; | Material: | Steel; |

| Service: | Design and Manufacture; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,Negotiable; |

| Place of Origin: | Jiangsu China (Mainland); | Delivery Time: | 1-4 weeks; |

| Tooth Profile: | Helical Gear; | Material: | Steel/Iron; |

| Equipment: | cnc machining center,cnc milling machine,cnc turning machine,etc; | Supply Ability: | 100000 Piece/Pieces per Month; |

| Color: | Black, etc; | Direction: | Left Hand; |

| Brand Name: | NO; | Processing: | Precision Casting; |

| Certification: | ISO 9001:2008;IATF16949; | Surface treatment: | Anodization,coat of antirust oil , plating,oxidatio etc; |

| Packaging Detail: | CARTON. SPECIAL REQUIREMENT IS ACCEPTED. Black Oxidation Steel Iron Casting Large Spur Gear; | Standard or Nonstandard: | Nonstandard; |

| Pressure Angle: | 20/40/50/60 Customized; | Name: | Black Oxidation Steel Iron Casting Large Spur Gear; |

| Port: | shanghai; |

OEM oem brass by drawing, brass machining part, brass valves

ISO9001:2008

IATF16949:2009

REAL REAL REAL ! NO FAKE, NO FAKE, NO FAKE !

Rabily (Kunshan) Manufacturing Co., Ltd. Headquartered in Shanghai with factories located at cities around Shanghai of KunShan, SuZhou, Taicang and Yancheng. Rabily proivdes customers with mechanical parts and even assembly service through various manufacturing processes.

Headquarter and Subsidiaries

| Location | Covering area | Business |

| Shanghai Headquarter | 1000 square metre | R&D,Financial,Sales |

| Kunshan CNC Factory | 2500 square metre | Manufacturing Hub, Project, Customer Service |

| Kunshan Plastic Injection Factory | 3500 square metre | Plastic (PC/ABS/PA) Injection Products |

| Suzhou Sheetmetal Factory | 3000 square metre | Sheetmetal, Stamping Products |

| Suzhou Die Casting Factory | 3000 square metre | Die Casting Products |

| Taicang | 5000 square metre | Fastener |

| Yancheng | 6000 square metre | Mass Production Base, CNC+Die Casting+Painting |

| Process | ||

| CNC Milling | Die Casting | Fastener |

| CNC Lathing | Heat Sinks | Assembly Service |

| Lathing & Milling | Plastic Injection | Laser Engraving |

| Drawing Format | IGS,STP,X_T,STEP,DXF,Pro/E,CAD,PDF | |

| Test Equipment | measurement instrument ,Projector,CMM ,Calipers.Pin Gauge etc. | |

| Material | ||

| Aluminum | 6061/6063/6082/2014/7075/7050/5052/ADC12/A380 | |

| Stainless Steel | 303/304/3016/412/17-4/316L | |

| Carbon Steel | 1018/1020/1045/A3/Q235 | |

| Alloy Steel | 4130/4140/4340/40CR/42CR | |

| Copper | C10100/C1100/C12200 | |

| Brass Alloy | 3602/2604/H59/H62 | |

| Plastic | POM/Delrin/Polyurethane/Nylon/ABS/Acetal | |

| Surface Finish | ||

| Aluminum Parts | Stainless Steel Parts | Steel |

| Clear Anodized | Polishing | Zinc Plating |

| Color Anodized | Passivaing | Black Oxide |

| Sandblast Anodized | Laser Engraving | Nickel Plating |

| Chemical Film | Sandblast | Chrome Plating |

| Brushing | Heat Treatment | |

| Polishing | Powder Coated | |

| Chorming | ||

| Equipments | ||

| 3 axis/4 axis CNC Machining Center | Punching Machine | Laser Cutting Machine |

| CNC Lathes | Pressing Machine | Die casting machine |

| Grinding Machine | Drilling Machine | Injection molding machine |

| Milling Machine | Threading Machine | Lase Engraving Machine |

1.How can I get quotation and feedback for my products?

Provide your 2D drawings with specifications (material, surface treatment, tolerance, other requirement, etc.); Please inform your quantity usage (MOQ and annual need) and logistic requirement; 3D drawings are much welcome for full product review.

2.How long can I get the quaotation?

Normally, we can provide instant feedback and then provide quotation within 48 hours

3.How long will you produce the parts?

Production lead time for CNC machining is 1-4wks, according to difference products and quantity. We will communicate with Customers on production plan and delievery for each PO.

If a mold is needed, the mold making time will be:

1) 2-3wks for extrusion molds

2) 4-8wks for die casting molds or plastics injection molds

3) 2-3wks for stamping molds

4.What's your payment terms

1) Especailly for new customers: T/T in advance or 50% T/T in advance, left needs to be wired before delivery.

2) L/C

5.Incoterms:

1) Ex-works or FOB Shanghai, is preferied;

2) CIF

3) DDP: need further communication on cost & logistics issues with Customers

6.Shipment: By Air or Ocean

Normally by air for samples (if not too heavy)

7.Will you sign NDA?

Yes, NDA is necessary between us.

8. Refund Terms:

We support refund policy for bad products, but customers must return back the bad products and in charge of the shipping cost.

-

Custom Sprocket Sprocket, Sprocket Sprocket Assembly

-

High precision spur gear pinion

-

Cheap High Precision Small Gear Micro Spur Gear Small Diameter Custom Cnc Machining Stainless Steel Sprocket Gear

-

Steel forging cylindrical involute tooth gear 0.25 modulus gear

-

Factory supply high quality tractor drive shaft planetary gear

-

Custom CNC milled brass machined gears

-

Factory custom high precision custom metal spur gear manufacturer steel spur gear steel gear

-

Hardened straight rack tooth surface heat treatment 1/1.5/2/2.5/3/4/5 mold rack

-

helical metal spur gear

-

Wholesale high quality spline sleeve manufacturers offer