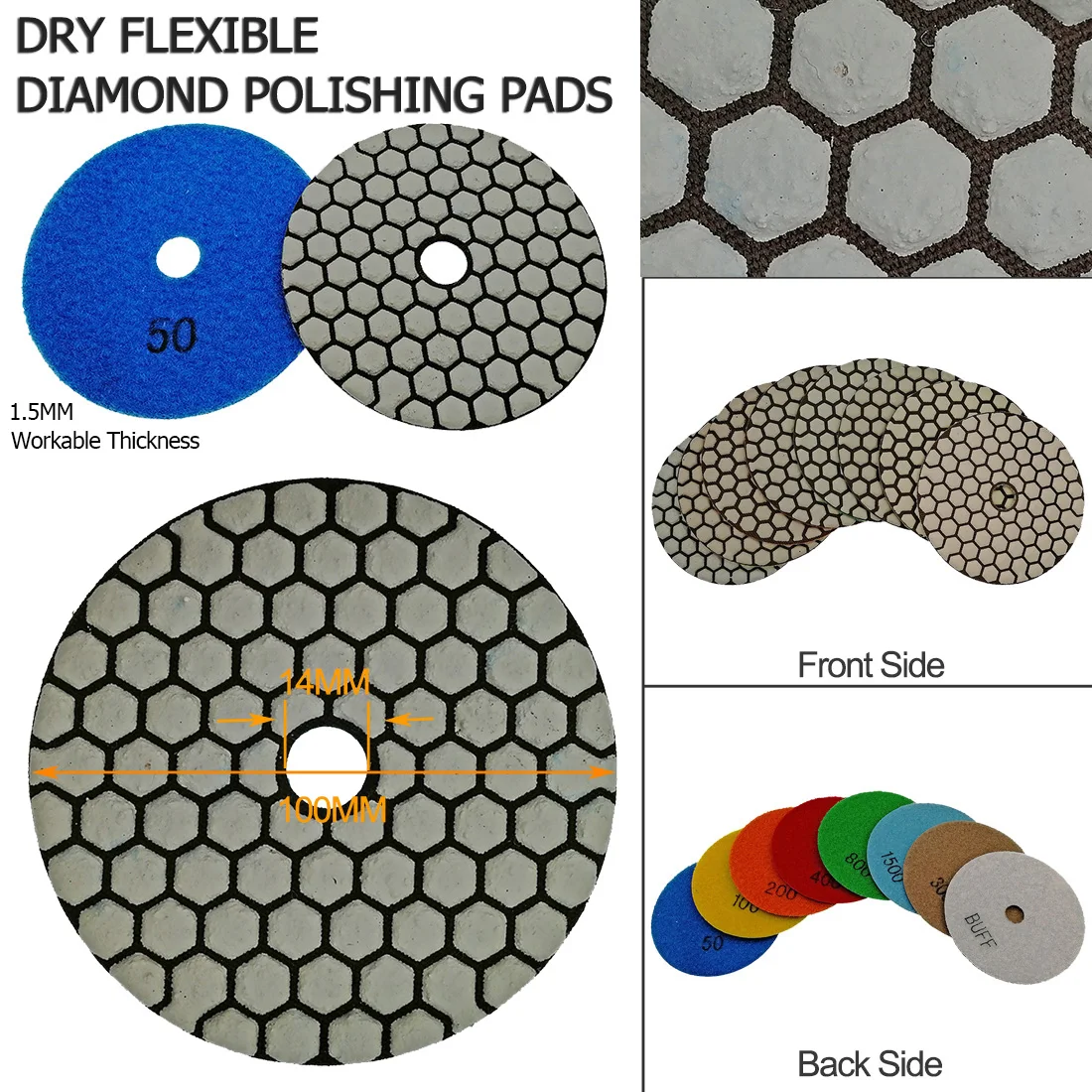

DIATOOL 4" Resin Bond Diamond dry sanding disc 100mm Flexible Diamond Dry Polishing Pads granite marble Grinding disc

-

Supplier: Shanghai Diatool Co., Ltd. -

Region: Shanghai, China -

Contact: Mr Michael Yao -

Price: $1.30 / >=1000 sets -

Min. Order: 1000 sets

| Payment Terms: | T/T,Western Union,PAYPAL; | Supply Ability: | 200000 Piece/Pieces per Month; |

| Brand Name: | SHDIATOOL; | Place of Origin: | Shanghai China; |

| Inner Diameter: | 14mm; | Grit: | 50# 100# 200# 400# 800# 1500# 3000# BUFF#; |

| Packaging Detail: | Paper Box and Carton; | Size: | 100mm; |

| Port: | SHANGHAI, TIANJING, NINGBO; | Substrate: | Resin+Diamond; |

| Application: | polishing; | Model Number: | A6110415BS11.11; |

| Brand | Diatool |

| Main material | diamond |

| Size | 100MM / 4" |

| Function | polishing |

| Thickness | 1.5mm or customized |

| Grit | #50 #100 #200 #400 #800 #1500 #3000 #BUFF |

| Quantity available | 100000pcs |

| Shipping time | 30-40days |

Dry polishing, working without water, convenient and less pollution

Very competitive at price,

Company Information:

We are a professional manufacturer & supplier of diamond tools in China. We had been in this business line for more than 20years. We can provide the following products for use with granite, marble, concrete, ceramic tile, glass, and steel:

Diamond cutting discs / saw blades

Diamond polishing pads

Diamond grinding wheels / bits

Diamond drilling core bits

Other diamond tools accessories (router bits, engraving bits, backer, etc.)

Please contact us if you are interested in bulk orders

If you have any further questions about our company, services, or production, feel free to contact us!

"Steady. Quality. Service."

Our Market:

Certificate:

FAQ:

Question1:How to get the prices?

Answer:Please kindly let us know your detailing inquiry information:

1.Item code, detailing specification, application, required quantity

2.We would response in two days

Question2: How about delivery time?

Answer: It is upon the your required quantity and the production condition

Generally we would ship your goods within 30 days

Question3: Why Core Cracks

Answer:

1.Blade too hard for the material being cutting.

2.Excessive cutting pressure, cause the blade core bending

3.Blade fixed wrongly, or damaged machine condition

Question4: Segment Fall-off

Answer:

1.Blade has twisted or jammed in the cut because the material was not held firmly

2.Blade is too hard for the material cutting, result in the blade hammering in the cutting.

3.Over heating due to inadequate water feeding.

4.Choose the blade with protection teeth

5.Blade fixed wrongly, or damaged machine condition, worn bearing

Question5: Blade tremble

Answer:

1.Damaged machine condition, shaft is bent or grooved

2.Blade out of tension.

3.incorrect blade speed.

Question6: Blade dosen't work

Answer:

1.New blade is not exposed well or bond of segments is too hard and diamond is easy off

2.Check the blade is for the right application, check the direction of rotation.

3.The machine is not powerful enough

Question7: Overheating and segments burned

Answer:

1.Wet cutting, inadequate water feeding

2.Dry cutting, too long time cutting with excessive pressure

Packaging & Shipping:

Contact us:

Tel: 0086-21-64420724

Fax: 0086-21-54420727

Website: http://www.diatoolco.com

-

LARIX 5" Hook and Loop Abrasive Purple Sanding Disc Round Sandpaper

-

T27 Zirconia Alumina Louver 60 Grit with Angle Grinder

-

Quality Assurance Mesh Sandpaper Good Abrasion Resistance Polishing Sand Disc

-

Abrasive Tool Manufacturer 4 Inch Aluminum Oxide Louver Sanding Discs For Stainless Steel Metal Polishing

-

Perforated 6 Inch Round Sandpaper Purple Abrasive Sanding Discs For Car

-

High quality sanding disc back support sanding pad for sale

-

Red aluminum oxide grinding disc with cross hole sandpaper alox abrasive disc fiber disc

-

Grinding Blue Flexible Zirconia Flap Disc 115mm 125mm Metal Polishing Wheel

-

Premium 150mm Hurricane Purple Sandpaper Sandpaper Disc 6"

-

Round Hook and Loop Back Up Pads Car Polishing Pads for Use with Grinding Wheels

Other Products

-

$1.00 / piece

$1.00 / piece -

$0.89 / piece

$0.89 / piece -

$2.04 - $2.98 / piece

$2.04 - $2.98 / piece -

$24.84 - $34.56 / piece

$24.84 - $34.56 / piece -

$6.19 - $7.52 / set

$6.19 - $7.52 / set -

$10.67 - $13.19 / set

$10.67 - $13.19 / set -

$7.92 / piece

$7.92 / piece