Apparel machine parts Rotary Hook For Industrial Sewing Machine

-

Supplier: Xuernuo Industrial (Dongguan) Co., Limited -

Region: Guangdong, China -

Contact: Mr. Iven Wang -

Price: $1.00 / >=100 pieces -

Min. Order: 100 pieces

| Machine Type: | Sewing Machine; | Material: | aluminum; |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; | Service: | Customized OEM; |

| Model Number: | Rotary Hook; | Port: | SHENZHEN; |

| Process: | Cnc Machining; | Tolerance: | +/-0.05mm; |

| Application: | sewing machine parts; | Product name: | Apparel machine parts Rotary Hook For Industrial Sewing Machine; |

| Keyword: | Auto Car Parts; | Packaging Detail: | bubble packed individually then put in carton to prevent from damaging and scratches in transporting.; |

| Supply Ability: | 200000 Piece/Pieces per Month; | Delivery Detail: | 25 working days; |

| Color: | silver; | Place of Origin: | Guangdong China; |

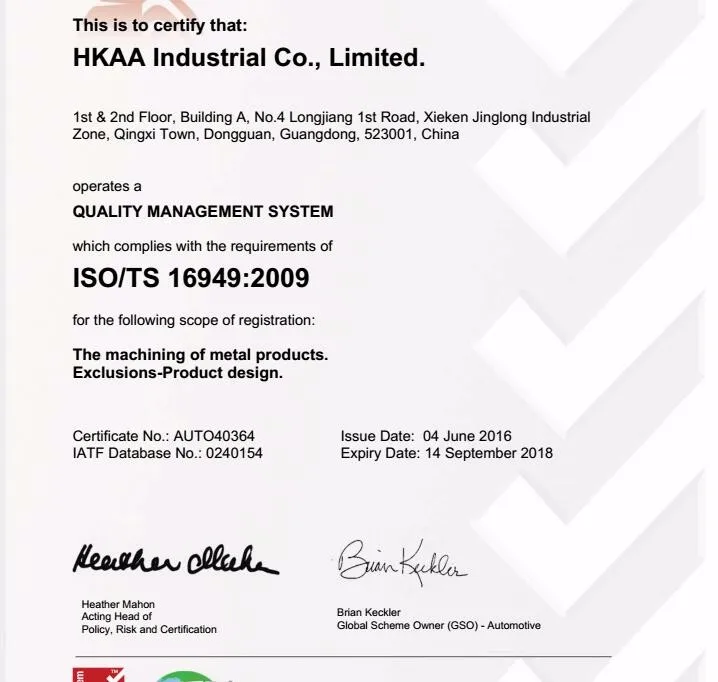

| Certificate: | ISO9001:2008; | Use: | Industrial; |

| Test Equipment: | Projector; | Type: | Hooks; |

| Brand Name: | HK AA; |

Apparel machine parts Rotary Hook For Industrial Sewing Machine

2. custom hardware parts

3.14-years manufactory

Specialty Custom Hardware Manufactory!

Surface: as your requirement

Material: stainless steel / aluminum / brass / iron / zinc / alloy steel / carbon steel

Any other material and dimension depends on customers' demand.

Usage: machinery / furniture / toy / woodboard / wall

Manufacturing process: lath machining, cnc machining, linear cutting, stamping machining

Euipment: lathe machine, cnc machine, punching machine, stamping machine

Testing equipment: projector

Tolerance:+/-0.05mm

We are willing to provide with sample for quality and function testing.

We are ISO 9001: 2008 certified firm.

Packaging

Shipping

1. FedEx/DHL/UPS/TNT for samples and small quantity parts, Door-to-Door;

2. By Air or by Sea for large quantity products,

3. Customers specifying freight forwarders or negotiable shipping methods!

4. Delivery Time: 10-25 days for samples; 20-35 days for batch goods.

2. MOQ: 1pcs

HK AA Industrial Co,. Limited, was founded in 1998, taking up more than 10000 square meters . we specialize in hardware, plastic products. machining parts ,stamping parts and fabricating parts. HK AA has 50 CNC turning machines, 10 stamping machines, 10 CNC milling machines, 10 automatic lathe machines, and 10 edge milling machines. And also the subsidiary equipments, such as milling machines, tap grinding machines and so on.

Q1:How to guarantee the Quality of Industrial Parts?

A1:we are ISO 9001-2008 certified firm. we have the integrated system for industrial parts quality control. We have IQC (incoming quality control), IPQCS (in process quality control section), FQC (final quality control) and OQC (out-going quality control) to control each process of industrial parts prodution.

Q2:What's the Advantage of Your Parts for Industry Products?

A2:Our advantage is the competitive prices, fast delivery and high quality. Our employees are responsible-oriented, friendly-oriented,and dilient-oriented. our Industrial parts products are featured by strict tolerance, smooth finish and long-life performance.

Q3:what are our machining equipmengts?

A3:Our machining equipments include CNC milling machines, CNC turning machines, stamping

machines,hobbing machines, automatic lathe machines, tapping machines, grinding machines,

screw machines, cutting machines and so on.

Q4: What shipping ways our use?

A4:Generally speaking, we will use UPS or DHL to ship the products. Our customers can reach the

products within 3 days.If our customers do not need them urgently, we will also use Fedex and TNT.If the products are of heavy weight and large volumn, we will ship them by sea. This way can save

our customers a lot of money.

Q5:Who are our main customers?

A5:HP, Samsung, Jabil Group,Lexmark,Flextronic Group.

Q6:What materials can you handle?

A6:Brass,bronze,copper,stainless steel, steel,aluminum,titanium And plastic.

Q7:How Long is the Delivery for Your Industrial Part?

A7:Generally speaking, it will take us 15 working days for machining parts and 25 working days for

the for stamping parts products. But we will shorten our lead time according to customers' demands

if we are able to.

-

Sewing machine parts sewing accessories sakura lacquer

-

GROZ-BECKERT brand German sewing machine needle double needle lathe DP*5

-

PVC Edge Sewing Machine Table and Stand New Products

-

Industrial Sewing Machine Parts DA YU 160 Right Angle Side Connector (F536)

-

750W Industrial Electric AC Energy Saving Sewing Machine Servo Motor Sewing Machine Servo Motor Price

-

JUKI-8700 servo motor with direct drive

-

Five Bucket Table Household Sewing Machine Wooden Table and Stand

-

German Groz needle GROZ-BECKERT button door double date

-

household mini servo pedal 100w sewing machine motor

-

Tajima 5.5'' Magnetic Frame 5.5'' Magana Hoop for Tajima Toyota 355mm BAI Machine Magnetic Hoop Embroidery

Other Products

-

$4.50 / piece

$4.50 / piece -

$5.70 / piece

$5.70 / piece -

$0.01 / piece

$0.01 / piece -

$3.01 / piece

$3.01 / piece -

$1.00 / piece

$1.00 / piece -

$3.00 / piece

$3.00 / piece -

$3.00 / piece

$3.00 / piece -

$2.00 / piece

$2.00 / piece -

$0.01 / piece

$0.01 / piece -

$20.00 / piece

$20.00 / piece