Industrial Electric Hot Knife Cutting For EPS Foam

-

Supplier: Changzhou Canty Electric Industry Co., Ltd. -

Region: Jiangsu, China -

Contact: Mr Jiazhong Cheng -

Price: $60.00 /set -

Min. Order: 1 set

| Supply Ability: | 6000 Piece/Pieces per Month; | Frequency: | 50Hz, 60Hz; |

| Port: | Shanghai; | Rated Voltage: | 230V, 120V; |

| Weight: | 0.4Kg; | Place of Origin: | Jiangsu China (Mainland); |

| Dimensions: | 26*5*3.5cm; | Packaging Detail: | Plastic Tool Box, (35/27/10cm) 6pcs/Carton Hot Knife Cutting For EPS Foam; |

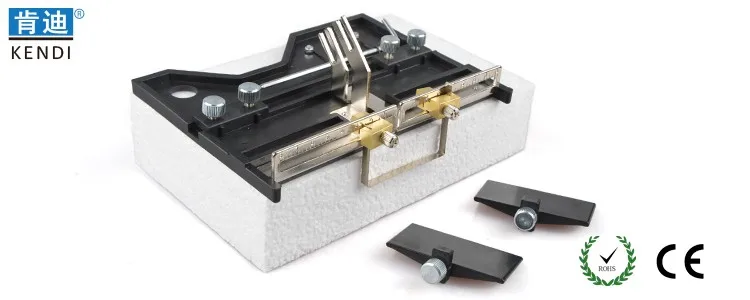

| Product name: | Hot Knife Cutting For EPS Foam; | Model Number: | KD-5; |

| Power Source: | Electricity; | Colour: | Blue, Red, Orange; |

| Brand Name: | CANTY; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,Hot Knife Cutting For EPS Foam; |

Industrial Electric Hot Knife Cutting For EPS Foam

| 1.Hot Knife EPS Foam Cutter Quantity |

Special making heating cutter since 2006,

Exported to world wide market.

All of cutters are CE certified.

| 2.Hot Knife EPS Foam Cutter Introduction |

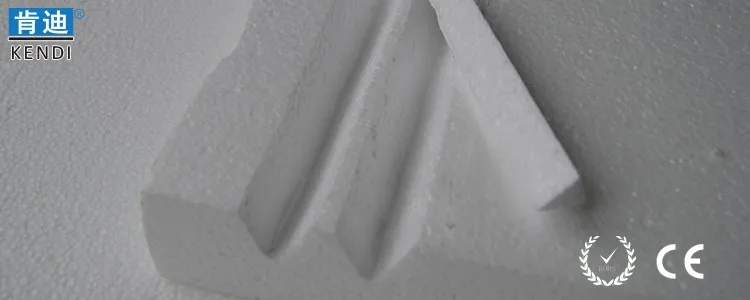

The KD-5 Hot Knife is a professional-grade hot cutting tool for foamed plastics. The KD-5 Hot Knife heats up in seconds and gives the operator temperature control. Never before has working with foamed plastics been this easy, inexpensive and free of mess.

| 3.Hot Knife EPS Foam Cutter Preparations |

Put your temperature control knob at midrange setting, place the blade against the edge of the foam and depress trigger. Optimum cutting should be virtually smoke free.

NOTE: For the best results, practice on scrap pieces of foam.

| 4.Hot Knife EPS Foam Cutter Recommended Use |

Expanded Polystyrene (EPS), Extruded Polystyrene (XPS), Polyethylene, Cross-Linked Polyethylene, Polypropylenes, and many other foamed plastics and materials can be easily cut with KD-5 Hot Knife. Check with the foam manufacturer for safe and proper cutting procedures

When cutting foam it is best to keep the temperature and speed consistent. If smoke develops during the cut, you are cutting too slow or the blade is to hot which could result in an oversized, uneven cut. This can be remedied by lowering the temperature and intermittently releasing the trigger during your cut. As the cutting resistance increases, depress the trigger again. The KD-5 Hot Knife will reach the set temperature within seconds. You can accomplish your cut with minimal smoke using this process. Cutting in this manner will also prolong the life of the knife.

Releasing the trigger approximately one or tow inches prior to the completion of the cut will help keep the blade clean and free from buildup

The selected cutting blade should not be longer than 3/4” past the thickness of your foam board. The foam cools the blade as it cuts. The exposed portion can overheat and cause your blade to warp.

| 5.Hot Knife EPS Foam Cutter Maintenance |

Constant use of the KD-5 Hot Knife may result in polystyrene material build up on blades and the brass holders. This excess polystyrene interferes with the proper electrical and impairs the performance of the blades. The brass blade holders and blades can be thoroughly cleaned with a wire brush.

| 6.Hot Knife EPS Foam Cutter Details |

| INPUT | 230 Volts |

| OUTPUT | 150 Watts |

| Intermittent Operation | 15s on / 45s off |

| WEIGHT | 10 Ounces |

| LENGTH | 260mm |

| WIDTH | 50mm |

| TEMPERATURE | 600 ℃ |

| 7.Hot Knife EPS Foam Cutter Attachments |

Sled

The sled enables you to make wider, more elaborate cuts, with the stock blade material and hard wire bending pliers you can produce thousands of different cuts.

Adaptor

The Adaptor is to hold the

curved blade "C shaped" for

plastic pipes with 20mm, 27mm

and 34mm diameter

150mm Flexible Blade(Especially for small grooving)

| 8.About CANTY |

Changzhou Canty Electric Industry Co.,Ltd

As the earliest special manufacturer of heating cutter in China. Canty Electric Industry has been committed to the research and development of the products for 15 years.

Our products has been used in cutting EPS and XPS Foam, Synthetic Fiber rope, fabric, belting, etc. Originally we mainly produce AC tools and equipments. In 2013 we developed the first Cordless foam cutter with Li-ion battery in the world. In 2015 we developed the highest function CNC Foam Cutting machine (with Turn table, Lathe). We also produced Mineral Wool Board Cutting Machine for building area.

With Canty you get Service, Quality and Innovation Heating cutter back by 15 years’ experience.

| Certificates |

-

Manufacturer riveting tools wholesale cordless rivet gun electric rivet gun

-

4 Pieces Power Tool Set Portable Lithium Electric Hammer Drill Brushless Angle Grinder Cordless Wrench Combo Tool Set

-

1700w Best Electric Portable Super Wall Mill Slotting Cutting Slotting Machine Wall Panel Price

-

Hot Sale Concrete Cutting Machine Concrete Hydro Installation Cutting Wall

-

7-Tool Kit Rolling Toolbox 20-Volt MAX Lithium-Ion Cordless Combo Top Quality

-

Coofix CF-MFS001 Variable Speed Electric Multi-Function Saw Oscillating Multi Tool Swing Shovel

-

COOFIX 800W 115MM High speed blender electric motor concrete mixer machine

-

Dust-free Wall Chaser Machine for Wall Groove Cutting Slotting for sale

-

3-in-1 Hot Knife Foam Cutter 100-240V /9W Styrofoam Cutting Pen Kit

-

550W 6.35mm professional electric renovator twist a saw

Other Products

-

$58.00 / set

$58.00 / set -

$4000.00 / set

$4000.00 / set