OEM Custom High Precision Cast sea water pump impeller

-

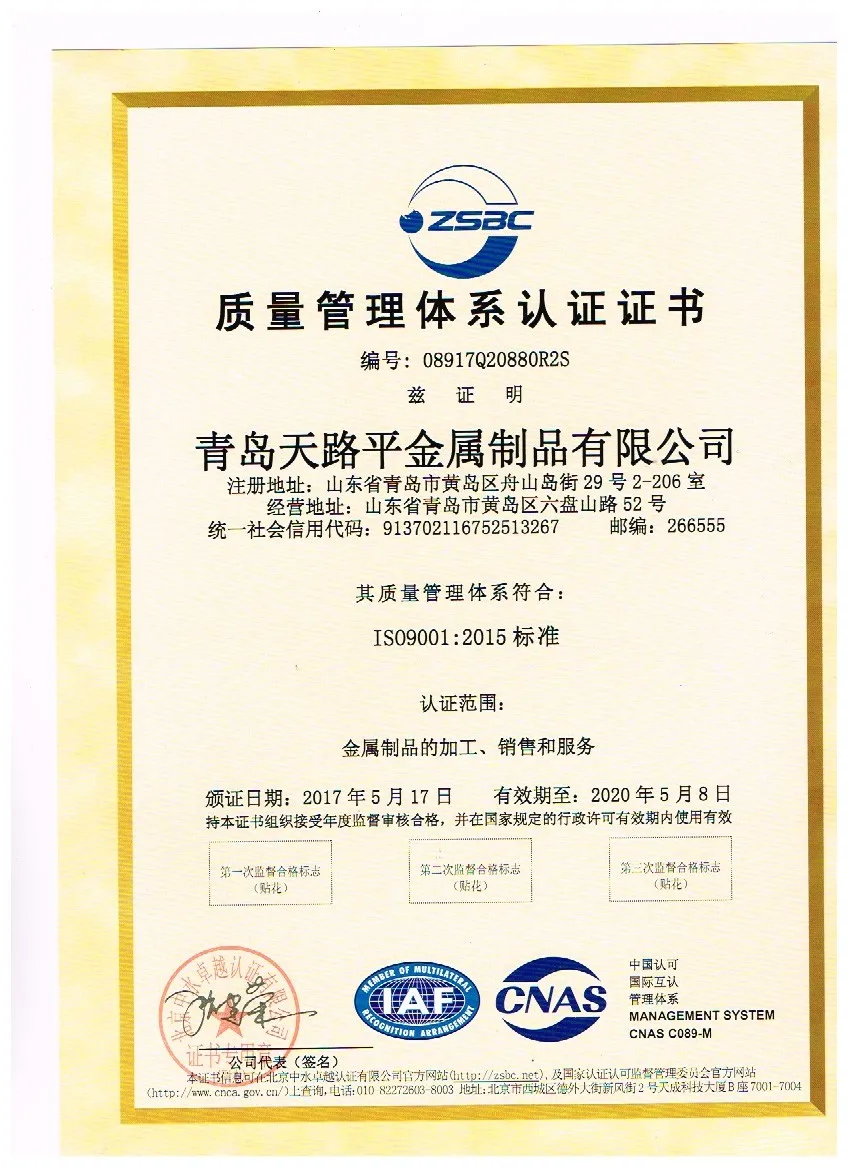

Supplier: Qingdao Tianluping Metal Products Co., Ltd. -

Region: Shandong, China -

Contact: Ms Zhenyuan L -

Price: $3.20 / >=500 pieces -

Min. Order: 500 pieces

| Delivery Detail: | 30days; | Service: | OEM ODM; |

| Pump Parts & Accessries: | Impeller; | Standard: | ANSI; |

| Process: | Gravity Casting; | Model Number: | TLP; |

| Product name: | ductile iron cast; | Port: | qingdao; |

| Place of Origin: | Shandong China; | Brand Name: | TLP; |

| Certification: | ISO9001-2008; | Packaging Detail: | Wooden case, pallet, or as the customers'requirements for the castings . If the customers allowed ,we will choose the suitable package for the customers . Generally we choose the 20 container for the product of the largest weight .we are promised that we will make the best package for the product at the reasonable price.; |

| Payment Terms: | T/T; | Supply Ability: | 360 Ton/Tons per Month; |

| Surface treatment: | Powder Coating; | Standard or Nonstandard: | Nonstandard; |

Product Application

Sand casting is used to produce a wide variety of metal components with complex geometries. These parts can vary greatly in size and weight, ranging from a couple ounces to several tons. Some smaller sand cast parts include components as gears, pulleys, crankshafts, connecting rods, and propellers. Larger applications include housings for large equipment and heavy machine bases. Sand casting is also common in producing automobile components, such as engine blocks, engine manifolds, cylinder heads, and transmission cases.

pump impeller or slurry pump parts

Sand Casting Base

GG25 or GGG25

Sand casting process

Lost Wax casting process

pump impeller or slurry pump parts

Sand Casting Base

GG25 or GGG25

Sand casting process

Lost Wax casting process

pump impeller or slurry pump parts

Sand Casting Base

GG25 or GGG25

Sand casting process

Lost Wax casting process

pump impeller or slurry pump parts

Sand Casting Base

GG25 or GGG25

Sand casting process

Lost Wax casting process

Main Features

(1)We have more experience in the casting industry for more than 15years

(2)We have development and design center formed by our experienced engineers

(3)We have a big warehouse combining quality control, inspection,packaging.

(4)Better quality with delivery on time service

(5)Competitive price by efficient working and capacity of large foundry

(6)OEM services

TLL is a casting foundry which produces variety kinds of metal parts in different casting process

Based on 15 years’ experience of casting, we built up our own designing and researching group, and have more experiences in different kinds of technologies, such as precision casting, investment casting in silica sol and water glass casting process, sand casting, die aluminum casting, forging and stamping. Engineer has skill to quick model parts using CAD, SOLIDWORK,PRO-E, and choose proper feeders for the part molds, thus will greatly shorten the developing time.

Except that, we also set up our quality control system and big warehouse, which combine inspection, testing, and packing together. The comprehensive inspection machines help us to make sure of quality. Each step is controlled strictly by inspection machines and tools, fixtures, 100% inspection. Usual testing machines: 3 coordinating machine, hardness testing machine, stress machines, pull machines and so on.

Our goal: good service, qualified products to meet customer demand,

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

-

DOOSAN 65.06804-000 Marine Impeller JMP 8201-01 Flexible Marine Impeller for DJ Pump Open Rubber Pump Parts

-

replace water pump impeller kit Sherwood 26000K-SHW Ancor 5063 3972366 DJ PUMP 08-34-1201 repair kit 19879 O-Ring

-

DONGYIN 4SD 3T Water Pump POM Plastic Impeller Submersible Pump

-

Industrial water pump air compressor motor plastic fan blade

-

centrifugal compressor alloy steel impeller

-

Manufacturers sell custom slurry pump impeller pump accessories blade impeller

-

Plastic impeller industry centrifugal water pump

-

Factory direct sale Y2 plastic motor blade motor wind blade

-

JetMan Outboard Jet Impeller Series Medium, Part No.1737, 8.23 (for liner #1521)

-

Flexible Rubber Impeller Replacement Jabsco 18786-0001 CEF 500153 CAT 7E3022 9Y5427 Neoprene Impeller

Other Products

-

$14.50 / piece

$14.50 / piece -

$3.20 / piece

$3.20 / piece -

$3.20 / piece

$3.20 / piece -

$30.00 / piece

$30.00 / piece -

$2.90 / piece

$2.90 / piece