100L 200L 300L 500L 700L 1000L 2000L steel brewing micro craft beer brewery equipment

-

Supplier: Shandong Shendong Fermentation Equipment Co., Ltd. -

Region: Shandong, China -

Contact: Mr NDLCRAFT Team -

Price: $1199.00 /set -

Min. Order: 1 set

| Weight: | 1200KG-5000KG; | Condition: | New; |

| Thickness: | Inner 3mm External 2mm; | Material: | Stainless Steel 304/316; |

| Processing: | Fermenting Equipment; | Voltage: | 220V/380V 50HZ/60HZ; |

| Capacity: | 100-2000L; | Applicable Industries: | Hotels,Manufacturing Plant,Food & Beverage Factory,Restaurant,Home Use,Food Shop,Food & Beverage Shops; |

| Selling Units: | Single item; | After-sales Service Provided: | Field installation, commissioning and training; |

| Heating method: | Steam, Electric, Gas; | Dimension(L*W*H): | Capacity Request; |

| Single gross weight: | 500 KG; | After-sales Service Provided: | Engineers available to service machinery overseas; |

| Package Type: | 1. LCL/FCL(20GP/40GP/40HQ) 2. Packed with plastic film in fumigation free wooden case or fixed with iron frame 3. Customer's requirements available.; | Warranty: | 5 years; |

| Processing Types: | Craft Beer; | Fermentation: | 60/75 cone; |

| Function: | Making Beer; | Single package size: | 600X250X250 cm; |

| Control system: | Touch Screen; | Brand Name: | SDETBREW; |

| Place of Origin: | Shandong China; | Power(W): | 12-100KW; |

| Brewhouse: | 2/3/4 Vessels; | Certification: | CE ISO BV; |

| Package Preview: | https://sc02.alicdn.com/kf/HTB1PS6pXvWG3KVjSZFPq6xaiXXa4.jpg_640x640.jpg; | Name: | 1000l steel brewing micro craft beer brewery equipment; |

100L 200L 300L 500L 700L 1000L 2000L steel brewing micro craft beer brewery equipment

1. SDET Beer Brewery Main Configurations:

Main Parts | Main Components |

1. Milling System | 01.Malt Miller |

2. Heating System | 01.Steam Boiler(Optional) 02.Burner(Optional) 03.Electric Heating (Optional) |

3. Saccharification System | 01.Mash Tun/Lauter Tank & Brew Kettle/Whirlpool Tank(2 vessel) 02. Mash Mixer & Lauter Tank & Brew Kettle/Whirlpool Tank(3 vessel) 03. Mash Tun/Lauter Tank & Brew Kettle &Whirlpool Tank(3 vessel) 04. Mash Mixer & Lauter Tank & Brew Kettle &Whirlpool Tank(4 vessel) |

4. Fermentation System | 01.Fermentation Tank(Unitank optional) 02.Bright Tank |

5. Cooling System | 01.Glycol Tank 02.Glycol Unit |

6. Cleaning System | 01.Disinfection Tank 02.Alkali Tank |

7. Control System | 01.PID 02.PLC(Siemens) |

8. Packing system | 01.Bottling 02.Canning 03.Kegging |

2. Saccharification System

SDET experienced team of engineers and brewers work together to design every brewhouse. We meticulously focus on the details, like pump and valve placement, aiming to maximize brewhouse efficiency and ease of use. With a SDET Brewhouse you will hit your gravity targets quicker and run up and down the platform less often.

Whether you want to save space, money, and time by only using a 2 vessel mash and boil kettle or you need a dedicated HLT tank alongside them, we have a solution for you.

Our stainless steel vessel brewing systems are insulated using chloride-free, 100mm Rockwell insulation, keeping temperatures at exactly the level you need them to be.

They also allow you to produce batches at record speeds, from the beginning to the cleanup process. Maximize your brewhouse’s efficiency with our systems!

3. Fermentation System

SDET professional fermenters are made from stainless steel as it is easy to clean and can be reused almost indefinitely. They all have a valve at the very bottom of the cone which can be used to remove sediment, and also drain the finished beer for bottling or kegging when done. Most also have a second port higher on the cone which can be used to draw samples of beer for measurement or tasting.

Fermentation tank series | Volume in US Gallon | Diameter | Height |

100l Fermentation tank

| 26US Gallon | 640mm | 1500mm |

200l Fermentation Tank

| 53US Gallon | 760mm | 1800mm |

300l Fermentation Tank

| 79US Gallon | 860mm | 2000mm |

500l Fermentation Tank

| 132US Gallon | 960mm | 2350mm |

1000l Fermentation Tank

| 264US Gallon | 1260mm | 2650mm |

2000l Fermentation Tank

| 528US Gallon | 1560mm | 3150mm |

3000l Fermentation Tank

| 793US Gallon | 1800mm | 3550mm |

5000 Fermentation Tank

| 2642US Gallon | 2200mm | 6100mm |

10000 Fermentation Tank

| 5283US Gallon | 2200mm | 10200mm |

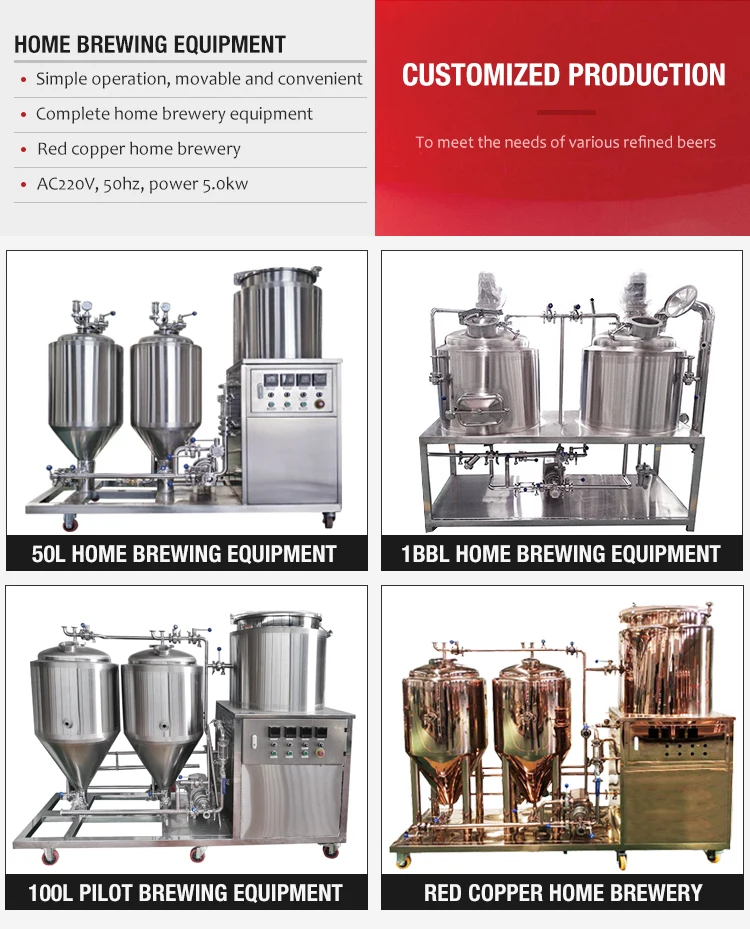

4. SDET Grouped Equipment

SDET offers all necessary peripheral equipment to ensure that your beer brewery equipment/ Brewpub has everything it needs for a high quality brew and the means to give your clients the best drinking experience.

Company Information:

SDET is one of the most well-known beer brewery equipment supply companies in China which has 40 years brewing experience and more than 10 years manufacturing experience.Our company combines both the world’s most sophisticated brewing technology with economical prices in order to provide our customers with the best equipment at an affordable price. Our product line caters to every possible customer in the market: from pilot systems / home brewery equipment to microbrewery equipment / macrobrewery as well as renovating or upgrading current commercial beer brewing equipment. If you are unsure as to what products to select or where to start, we will help you find EXACTLY what you are looking for.

Exhibition:

Sale cases:

SDET has passed International Certification, such as ISO, CE, BV etc

1.Pre-sales:

-Layout:Sent us your building floor plan, or the sketch, or tell us the size (length, width, height), we will offer you an equipment footprint according to your requirement.

-Technical Drawings : We will offer Technical Drawings of each tank based on the equipment layout .

-3D effective sketch: We will 3D effective sketch to make sure ensure you have a more intuitive experience.

2.After-sale

-We can provide weekly production report to let you clear of production progrss and production details;

-We will do equipment test and test report available for you;

-Providing piping connection drawing and English operation manuals;

-Providing equipment installation, debugging, and personnel training service;

-We can help you to arrange transportation till to your location;

-Main machine guarantee for three years; Accessories and electronic components will have one year free warranty; Supply lifetime maintenance and technical service.

1.With export standard bubble film packaging, then for wooden case packaging for alone beer tanks and less brewery equipment.-LCL shipping.

2.If more tanks or complete set of brewery, with bubble film packaging, the for containers for FCL shipping.

3.By bulk carrier or independent containers, the size and quantity rely on the configurations and capacity.

4.Buyers requirement on packaging and shipping, tell us in advance.

5.Transportation method: By sea/Railway/Road/Air.

-

New WiFi Guten 40L 50L 70L Anti-burn Home Brewing All-in-one Micro Brewery/Craft Beer Machine/Brewery Equipment

-

500L 1000L Household Commercial Beer Fermentation Equipment Brewery Brewery Equipment Beer Brewing Equipment

-

China Micro Brewery Equipment Supplier

-

3x20" Ribbon Wrap Heating Pad Warming Heater Band for Kombucha and Beer Brewing

-

High quality 5l 10l 20l translucent fermenting barrel brewing beer container with air lock for home use

-

ethanol production machinery in small capacity medical alcohol production plant

-

stainless steel olive oil storage tanks

-

Alcohol copper still whiskey distillation column with helmet for sale

-

Automatic Fermentation Barrel Venting Household Fruit Beer Enzyme Container with 2 Lids Plastic Fermentation Tank

-

For sale pilot micro craft beer producers 100 200 400 500 1000 2000 l liter 2 3 5 7 20 bbl system equipment for drinking beer

Other Products

-

$5699.00 / set

$5699.00 / set -

$5699.00 / set

$5699.00 / set