QHYKM80-C Corrugated carton box printing Chain Feeder Printing Slotting Machine

-

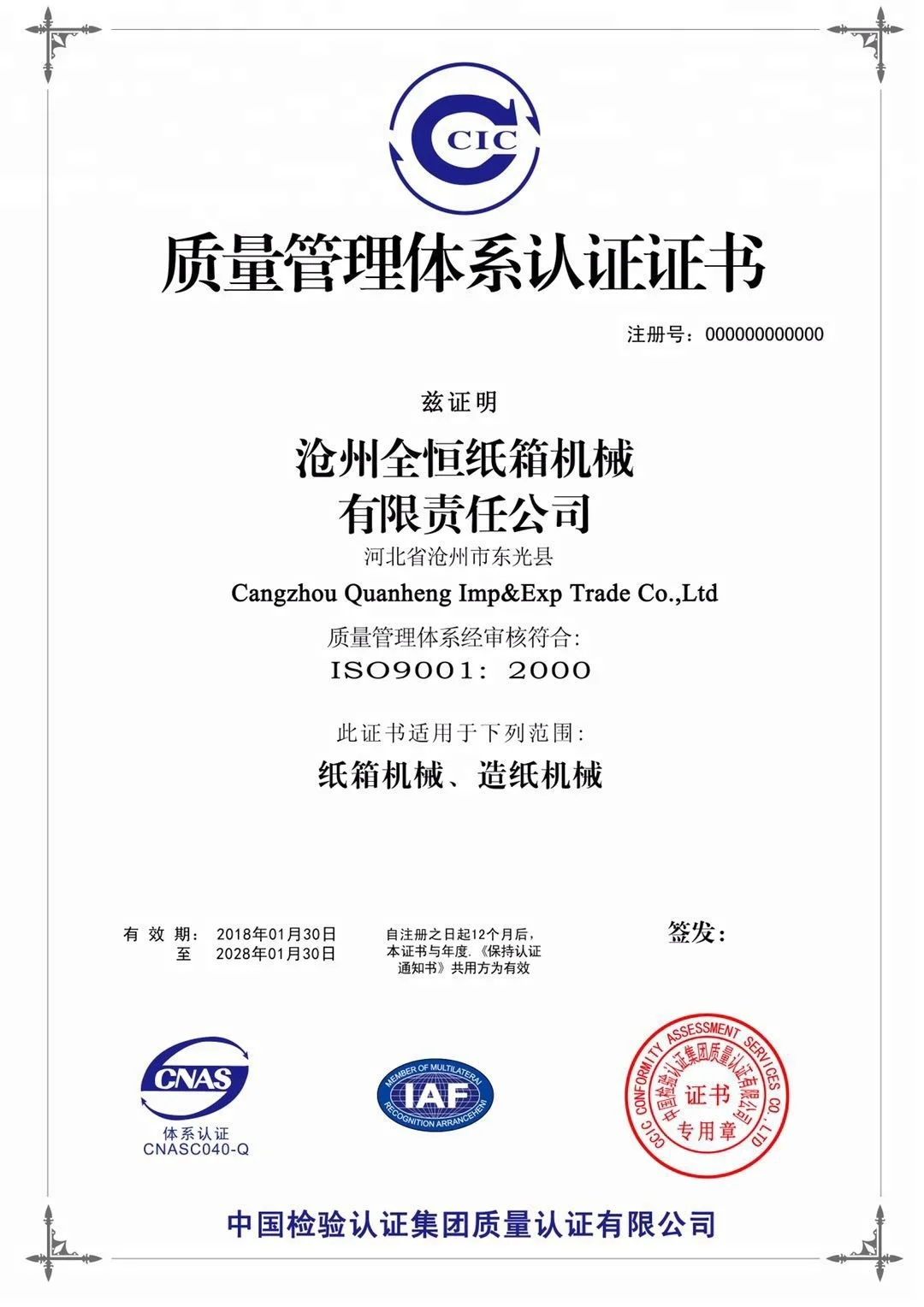

Supplier: Cangzhou Quanheng Imp & Exp Trade Co., Ltd. -

Region: Hebei, China -

Contact: Mr Jack Yan -

Price: $10000.00 /set -

Min. Order: 1 set

| Application: | Corrugated Carton Box Making Machine; | Name: | Corrugated carton box Chain Feeder Printing Slotting Machine; |

| Warranty: | 12 Months,1 YEAR; | After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; |

| Brand Name: | QH-PACK; | Voltage: | 220V/380V/440V; |

| Core Components: | Gearbox,Pressure vessel,Pump,Gear,Bearing,Engine,Motor,PLC; | Key Selling Points: | Multi Color; |

| Package Preview: | ; | After-sales Service Provided: | Engineer Service Oveaseas,Free spare parts,Field maintenance and repair service,Field installation, commissioning and training,Video technical support,Online support; |

| Machinery Test Report: | Provided; | Condition: | New; |

| Applicable Industries: | Garment Shops,Building Material Shops,Machinery Repair Shops,Food & Beverage Factory,Restaurant,Home Use,Food Shop,Printing Shops,corrugated carton box making manufacture; | Packaging Detail: | Standard; |

| Port: | Tianjin; | Speed: | 60pcs/min; |

| Video outgoing-inspection: | Provided; | Local Service Location: | Egypt,Brazil,India,Mexico,Russia,Spain; |

| Marketing Type: | Hot Product 2019; | Automatic grade: | Full-Atuomatic; |

| Place of origin: | Dongguang Cangzhou Hebei China; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; |

| Supply Ability: | 300.0 Set/Sets per Year; | Brand name: | QH-PACK; |

| Warranty of core components: | 1 YEAR; | Showroom Location: | Egypt,Brazil,India,Mexico,Russia; |

QHYKM80-C Chain Feeder Printer Slotter Machine

Main Technical Parameter:

|

Design Speed |

80pcs/min |

|

Economy Speed |

0-60pcs/min |

|

Color |

3color |

|

Max.Paper Sizes |

1400x2600 |

|

Min.Paper Size Positive knife Negative knife |

350x720mm 350x740mm |

|

Max.Printing Size |

1400x2400 |

|

Standard Printing Plate Thickness |

7.2mm |

|

Slot Width X Max.Depth |

7x300mm |

|

Min.Slot Space Positive knife Negative knife |

170*170*170*170 260*90*260*90 |

|

Printing roller dia(plus printing plate thickness) |

405mm |

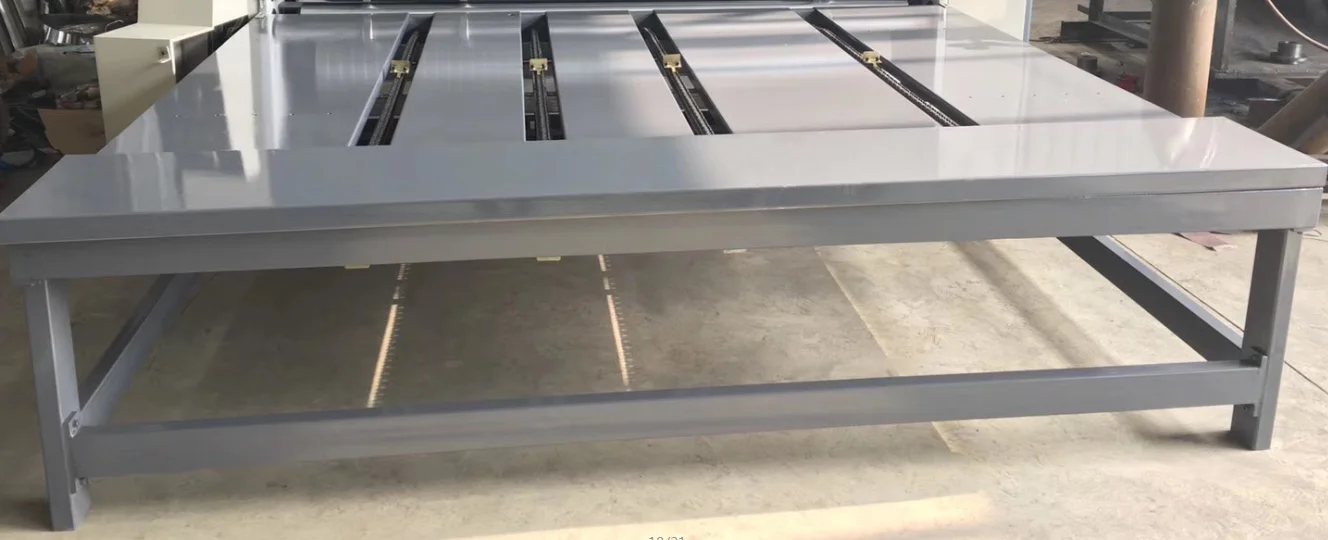

Feeding unit:

1. Chain feed type, double side baffle, high feeding precision and run steadily.

2. Chain paper feeder and main machine forms lineal-speed differential, back baffle open the distance after finishing feeding paperboard and will not damage paperboard.

Printing unit:

1. Static and dynamic correcting and drilling balancing, run steadily.

2. Space between printing and pressing roller adjusted by worm gear,dial gauge display numerical value, adjustable range 1-11mm.

Pneumatic lifting roller, prevent printing plate repeat inking and ink dry up when machine short time stopping.

3. Adopt LCD computer phase control instrument, makes operation more convenient and accuracy.

4. Pneumatic Diaphragm Pump, supply ink steady, operation and maintain easily.

5. Manual type axial adjustment structure, ±5mm.

Slotting unit:

1. Three unit for slotting,one unit for angle cutting,two unit for paper dividing and four unit for creasing.

2. Creasing roller space manual adjustment, adjustable range: 0-12mm

3. The width of slotting knives: 7mm

4. Trimming knife is made up of Alloy steel, heat treatment, grinded. Sharp, high precision

5. slotting height adjustment adopt four knife synchro control, electrical horizontal adjustment.

6. Slotting unit control pannel equipped with inching button, convenient for operator independent operation at end of machine.

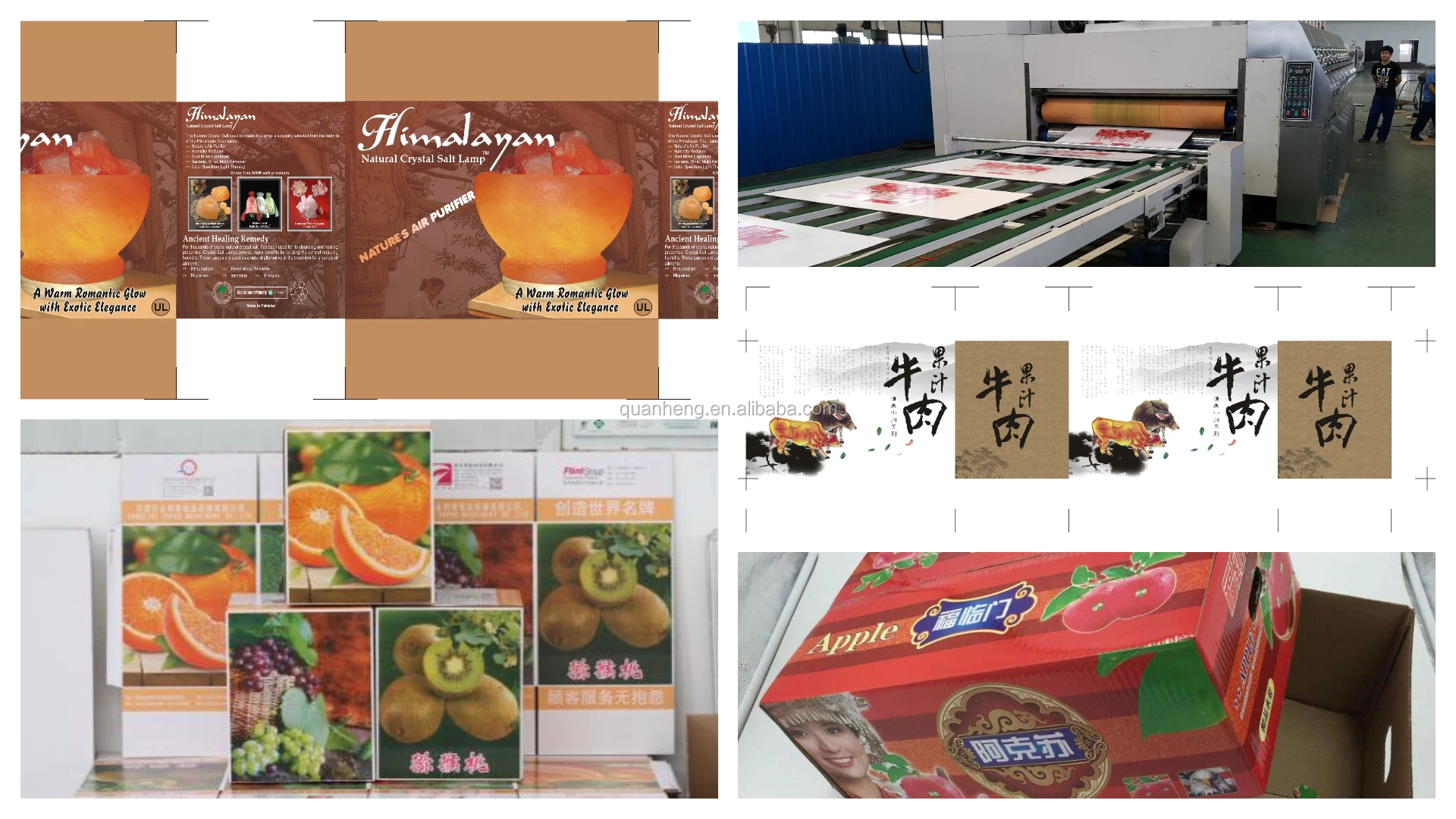

Sample:

Company information:

-

Chain feeder semi-automatic corrugated box 1-4 color pizza box printing machine

-

Fully automatic high-speed four-color corrugated box making machine carton printing slotting die-cutting machine

-

Tooth-shaped corrugated arc-shaped blade carton slotting machine cutting knife customization

-

Corrugated box eccentric slotting machine

-

Corrugated Cardboard Slotting Machine RS4 Corrugated Box Slotting Die Cutting Machine

-

Ocean corrugated cardboard pizza printing slotting die cutting machine

-

Corrugated box automatic flexo slotting die-cutting machine

-

HY-AA series chain feeding corrugated box printing slotting machine

-

Automatic carton flexo printing machine price Taiwan printing slotting die cutting machine carton printer slotting machine

-

High speed automatic carton flexo printing machine slotting machine rotary die cutting machine inline and carton folder gluer

Other Products

-

$170000.00 - $190000.00 / set

$170000.00 - $190000.00 / set