High Quality Hydraulic CNC Press Brake With Best Price And Best Service

-

Supplier: Jiangsu Tiptop Machine Tools Co., Ltd. -

Region: Jiangsu, China -

Contact: Mr Ethan Lau -

Price: $10300.00 /set -

Min. Order: 1 set

| Certification: | ce; | Warranty: | 2 years,2 Years; |

| Keyword: | CNC Press Brake; | Usage: | Metal Sheet Bending; |

| Width of Working Table (mm): | 220; | Bending Width: | 1600-12000mm; |

| Bending Thickness: | 0.5-40mm; | Supply Ability: | 50 Set/Sets per Month cnc press brake; |

| Model: | HPB Series; | Place of Origin: | Jiangsu China; |

| Bending Material: | Mild Steel, Stainless Steel, Aluminum, Copper; | Extra Services: | Piercing & Punching; |

| Showroom Location: | None; | Year: | New; |

| Length of Working Table (mm): | 3200; | Controller: | NC and CNC; |

| After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; | Payment Terms: | L/C,T/T,Western Union; |

| Slider Stroke (mm): | 140; | Package Preview: | ; |

| Packaging Detail: | cnc press brake:PVC film / Plywood Case; | Automatic Level: | Fully Automatic; |

| Throat Depth (mm): | 320; | Material / Metal Processed: | Brass / Copper,Stainless Steel,ALLOY,Carbon Steel,Aluminum; |

| After-sales Service Provided: | Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Video technical support,Online support; | Applicable Industries: | Machinery Repair Shops,Manufacturing Plant,Retail,Construction works ,Energy & Mining,Advertising Company,Metalworking Machinery; |

| Nominal Pressure (kN): | 1000 kN; | Weight (KG): | 6500; |

| Brand Name: | LETIPTOP; | Color: | Customizable; |

| Condition: | New; | Voltage: | 220V/380V/415V/600V; |

| Port: | Shanghai, China; | Machine Type: | Synchronized; |

| Motor Power (kw): | 7.5 kw; | Key Selling Points: | High-accuracy; |

| Local Service Location: | None; | Automation: | Automatic; |

| Dimension: | As per the model; |

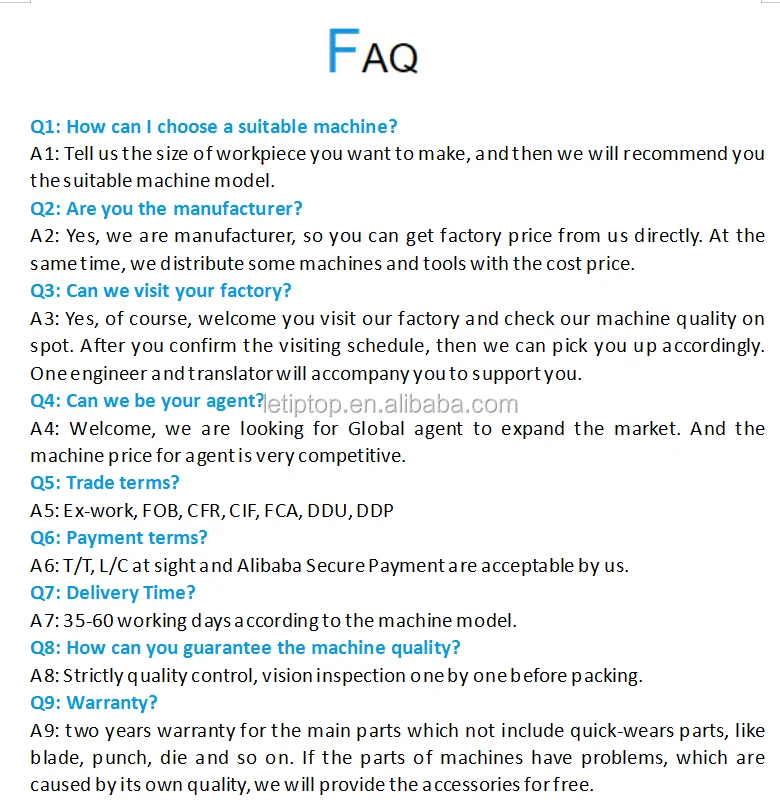

High Quality Hydraulic CNC Press Brake With Best Price And Best Service

Introduction:

The machine tool TIPTOP have been manufactured with the ability of listening and understand customer needs. The technological innovation and the continuous search for reliable and indestructible components make these machines for sheet metal working able to improve time business and production costs.

Safety in the workplace is invaluable for us. We manufacture SAFE machines! Operators can work with confidence thanks to the vehicle control systems, the worldwide leader in safety.The wide range of press brakes HOSTON varies by working force, size and production capacity.

Main Features

1. High Quality Components & System

a. Motor: Siemens, Germany

b. Main Electric Components: Schneider, French

c. Seal in the Cylinders: NOK, Japan

d. Valve: Atos, Italy

e. Pump: Sumitomo, Japan

f. Wiring Terminal Block: WEIDMULLER, Germany

g. NC Control System: Estun E21, China

2. Cost Effective

HPB SERIES Hydraulic Press Brake With Very good price/performance ratio

Various HPB SERIES Hydraulic Hydraulic Press Brake capacity from 30T to 4000T with width from 1,600mm to 20,000mm to meet your requirement.

3. Stable Performance & Reliable Quality

HPB Series Hydraulic Hydraulic Press Brake use hydraulic transmission. low noise, reliable performance.

4. Simple Operation

The operation of Hydraulic Hydraulic Press Brake is controlled by nc control system.

Product Categories → View All

cnc press brake

Hydraulic Ironworker

Hydraulic Shearing Machine

▶ ABOUT US

Jiangsu TIPTOP Machine Tools Co., Ltd. is a well known worldwide manufacturer of machines for sheet metal working, such as Hydraulic Ironworker, Hydraulic Shearing Machine, Press Brake, Plate Rolling Machine and Section Bender utilizing the most recent technologies and constantly refined by our design engineers to meet the most demanding market requirements for flexibility.

view more>>

Pre-Sales Service

* Inquiry and technology support

* Technical documents

All labels on machines and lay-out drawings, Electrical diagram, Operation Manual, will be in English. The seller should send all necessary files to the buyer since the third week since project execution. All documents in hard copies should be also shipped with machines together.

* Quantity and quality guarantee

a.Quantity/Quality Discrepancy to destination port during transportation:

In case of quality/quantity discrepancy to destination port in transportation, the buyer should file claim within 30 days after the arrival of the goods at port of destination. The seller will not be responsible for any discrepancy of the goods caused by shipping company and other transportation organization and/or post office.

b.Guarantee period and after-sales services: 13 months since date of bill of lading

During this guarantee period, the seller will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by your incorrect operations, the seller will provide the buyer spare parts at cost price.

* View our Factory.

After-Sales Service

* Arrangement for inspection, installation and testing work

a. After all machines are delivered to customer's factory; Buyer is responsible for all preparation work, e.g. electricity supply, water supply, labors and cranes, etc.

b. The buyer will prepare for visa application for their engineers, who are responsible for guide of machine installation and testing at the Buyer's factory.

c. The Buyer will buy the round-trip air ticket for Engineer if visa application is approved. The buyer is also responsible to bear expenses generated, e.g. visa formalities, meals, accommodation and allowance of USD80 per day for each engineer.

d. Engineer will give free training lessons to labors in buyer's factory.

*The seller will charge the buyer cost price of spare parts beyond one year and provide long-term technical guide.

*2 years quality warranty

Hydraulic Ironwoker

91.8% Response Rate

Hydraulic Punching Machine

91.8% Response Rate

Pipe Punching Machine

91.8% Response Rate

-

Manual or pneumatic table stainless steel sheet metal / sheet metal bending machine / plate bending machine

-

DAMA TP10 Hydraulic Press Brake Large Heavy Duty CNC Controller Hot Selling Press Brake

-

CAC-75W hydraulic angle steel bending machine

-

AH Press Brakes for (Manual, Hydraulic, NC Hydraulic, Manual Folding Machine, Power)

-

2022 European high standard low cost MB8 series 200Tons/3200 CNC bending machine for sale

-

3KW Plate Bending Machine Hydraulic Multifunctional Steel Plate Bending Machine

-

Manual Sheet Bending Machine Hydraulic Bending Machine Metal Bending Machine

-

(W1.0X610B, W1.0X915B, W1.5X1220Z ) small handbrake/disc & box brake with CE, best price

-

Tool molds on bending machines, press blades on bending machines

-

Hot selling hydraulic new bending machine sheet metal bending machine 80t 3000 4000 6000

Other Products

-

$14000.00 / set

$14000.00 / set