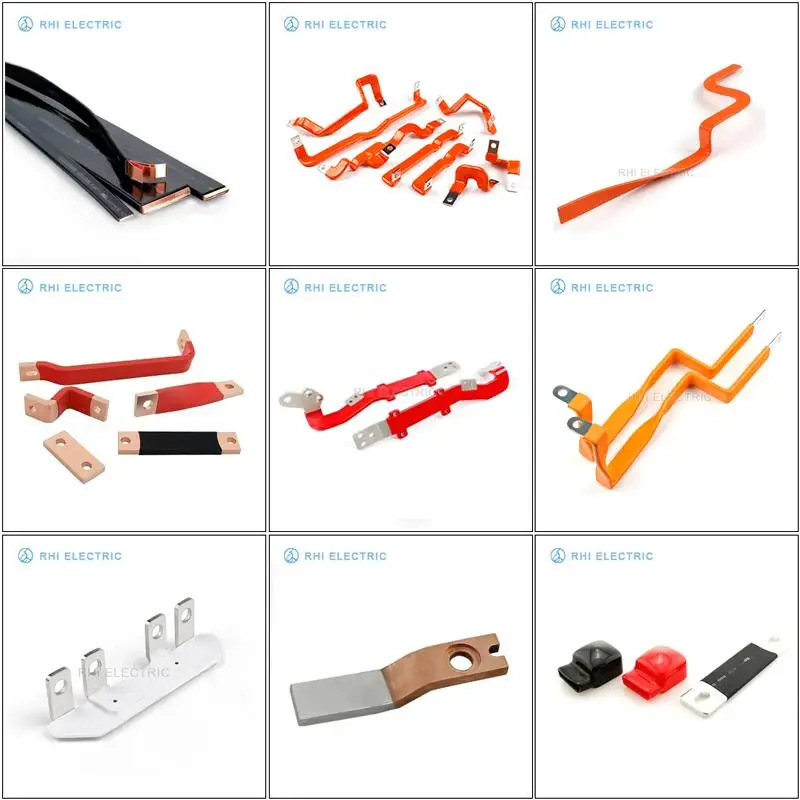

Nickel plated bus bar Copper battery hybrid prius busbar for electric vehicle

-

Supplier: Zhejiang Rhi Electric Co., Ltd. -

Region: Zhejiang, China -

Contact: Ms Alice Ye -

Price: $0.60 / >=100 pieces -

Min. Order: 100 pieces

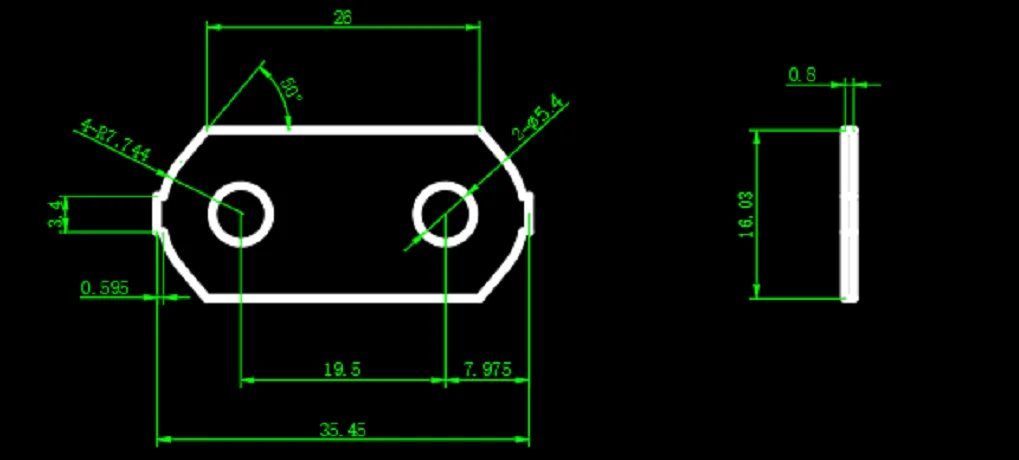

| Item Name: | prius busbar; | Application: | electric vehicle; |

| Thickness of plating: | 3-5 μm; | Selling Units: | Single item; |

| Surface Plating: | Nickel plated; | Single gross weight: | 0.004 KG; |

| Brand Name: | RHI; | Load Voltage: | 220V-1000V; |

| Model Number: | prius busbar; | Material: | copper; |

| Certificate: | ISO,Rohs,IATF16949; | Color: | Nickel color; |

| Copper Content: | 99.9%; | Edge Type: | Round, square, semicircle etc; |

| Single package size: | 5X2X1 cm; | Packaging Detail: | prius busbar carton, wooden box and pallet.; |

| Insulation Type: | Shrink sleeves, pvc, dipping etc; | Package Preview: | ; |

| Place of Origin: | Zhejiang China; |

Nickel plated bus bar Copper battery hybrid prius busbar

This nickel plated copper bus bar is for one Gen 1 Prius set in car/auto battery connection, plus one or 37 bus bars so if you accidentally drop one and then if you can't find it, you will still have enough to complete your Prius rebuild. These bus bars will improve the quality of your rebuild as the copper plated bus bars tarnish quickly and corrode easily - with a Nickel coating, they will not tarnish and corrosion is reduced about 10 fold - this makes future rebuilds much quicker and easier as there is no need to re-clean the bus bars!

| Material Standard | GB : T2 Copper with Min. 99.9% DIN: E-Cu58 (Number: 2.0065) EN: Cu-ETP ( Number: CW004A) ISO: Cu-ETP UNS: C11000 JIS: C1100 BS: C101 Other Material also can be customized |

| Resistance | 0.00001Ω |

| Conductivity | 57% |

| Copper busbar thickness | 1mm-10mm depend on bus bar structure, we will advise suitable thickness |

| Insulation Material | PVC Dipping Coating performs well for special shaped bus bar,which can be put on directly. It is not easy to break when it be bent with many times. |

| Flame Retardant/Fire Resistance | UL94-V-0 or upon you request |

| Leakage Testing | PVC Dipping Sleeves: In condition of 3500VDC with 30s upon thickness 1.5mm, Leakage is 0.025 MA; In condition of 5000 VAC with 30s to 60s upon thickness 1.8mm to 2.0mm, Leakage is 0.065 MA; Or upon your working voltage, we advise to choose better solution. |

| Surface Plating | Nickel, tin or silver plated etc Plating Thickness:Normally 3um to 12um or upon customers' request |

| Salt Spray Testing | In a neutral environment, nickel can bear 240 hours. Silver is lower, tin is lowest |

| Bending Testing | Bend 10000 times in 15 radian angle without breakage or fracture. |

| Temperature Rise Testing | Depend on flexible busbar cross-sectional area, We can offer all temperature rising test report before delivery if you request |

| Operating Temperature | -45 to +150 ºC |

| Copper busbar Tensile Strength | ≥500N |

| Quote Time | Quotation sheet will be sent in 1-3 working days when receive your enqiury |

| Sample/Trial Order Delivery Time |

In 5 -15 working days according to different bus bar structure and manufacture process |

| Quality Management Standard | Meet Auto Industry IATF 16949 |

| Eco-friendly Certificate |

|

|

|

|

|

Hybrid battery busbars are designed for use with the Hybrid Battery Pack modules of the following vehicles:

Toyota Prius GEN II (2004-2009)

Toyota Prius GEN III (2011 - 2015)

Nissan Altima (2007-2010)

Lexus CT200h

Testing Capabilities

| Test Programs | Tester | Standard | Test Result |

| Endurance test | Endurance meter | upon your request | √ |

| Release force test | Universal material testing machine | upon your request | √ |

| Loop resistance,contact resistance test | Loop resistance testing equipment | upon your request | √ |

| Temperature rising test | Temperature rising tester | GB/T14048.1-2000 | √ |

| Electric conductivity test | Conductivity tester | YS/T478-2005 | √ |

| Salt spray test | Salt spraying tester | GB/T2423.17-2008 | √ |

| Thermal ageing, heat vibration test | Air exchange aging test machine | upon your request | √ |

| Coating thickness test | X-ray coating thickness tester | upon your request | √ |

| Voltage drop test | Voltage drop tester | upon your request | √ |

1.Advanced Technology: We have industry-leading processes and technologies like automatic robot dipping, automatic robot welding, automatic copper forming and 20 years’ experience of busbar insulated dipping technology. With automation equipment and R&D team, we continuously improve our production efficiency and product quality reliability.

2.Efficient Supply Chain: From raw materials to finished products, all processes include mould and fixture are finished in our plant. Only the plating is finished by our supplier near our factory.

3.Superior Service: Give response in 8 hours, arrive at customer’s site to solve problem in 24 hours ( Site outside China may need to be extended).

4.Quick Response: With efficient supply chain and perfect production process, we can provide small batch products in a short time to support early development of customer’s project.

5.Quality Commitment: We are committed to the highest quality standards. Material is tested before production to guarantee it is ETP grade copper. All goods are inspected before delivery. We have certificates of ROHS, REACH, UL94V-0, ISO14000 and IATF16949.

6.Timely Delivery: Experienced workforce, large production capacity and sound supply chain guarantee timely delivery time for customer.

7.Competitive Price: With efficient supply chain and production environment in China, we have advantage of low cost.

-

Nickel plated carbon steel nut copper bus bar suitable for Toyota Camry 2007-2011 2012-2017 Lexus ES300h 2012-2017 hybrid car battery

-

Custom outdoor plastic case, waterproof plastic case for PC supplied from China

-

New safe portable waterproof and dustproof plug socket white distribution box industrial socket box with bracket

-

Power Supply Outdoor Enclosure Consumer Unit Electrical Distribution Box Stage

-

Best Selling Stage Light Plug Distribution Box Portable Distribution Box Industrial Socket Stage Power Supply

-

19" 2U Rack Mount Power Distribution Metal Box with Voltmeter

-

Twist Lock 30amp Inlet Power Distribution Rack Switchboard Box

-

Hot Sale Ip67 4 Way Plastic Window Cover

-

US Power Connector 110v Portable Electric Box

-

Dual power automatic transfer switch 63A 4P home generator switch complete set of distribution box distribution cabinet

Other Products

-

$0.05 / piece

$0.05 / piece -

$0.15 / piece

$0.15 / piece -

$1.00 / piece

$1.00 / piece -

$1.00 / piece

$1.00 / piece -

$0.30 / piece

$0.30 / piece -

$0.30 / piece

$0.30 / piece -

$0.50 / piece

$0.50 / piece -

$0.20 / piece

$0.20 / piece