Fully Automatic PP Industrial FDY Yarn Multifilament Yarn Spinning Machine

-

Supplier: Taian Jiamei Machinery Technology Co., Ltd. -

Region: Shandong, China -

Contact: Ms Susan Sun -

Price: $96000.00 /set -

Min. Order: 1 set

| Production Capacity: | 96; | Single package size: | 23X35X35 cm; |

| Condition: | New; | Core Components: | PLC,Motor; |

| After-sales Service Provided: | Free spare parts,Video technical support,Field installation, commissioning and training,Field maintenance and repair service; | Brand Name: | jiamei; |

| After Warranty Service: | Video technical support,Spare parts,Field maintenance and repair service; | Dimension(L*W*H): | 6*5.5*6.5m; |

| Certification: | ce; | Type: | Spinning Production Line; |

| Package Preview: | ; | Local Service Location: | Philippines,Brazil,Saudi Arabia,Indonesia,Malaysia; |

| Warranty of core components: | 1 Year; | Selling Units: | Single item; |

| Single gross weight: | 40.0 KG; | Capacity: | 90KG/HR based on 900denier; |

| Application: | Industrial,filament production; | Material: | Polypropylene; |

| Brand name: | JIAMEI; | Machinery Test Report: | Provided; |

| Winder speed: | 2400m/min; | Marketing Type: | Hot Product 2019; |

| Applicable Industries: | Manufacturing Plant,spinning plant; | Power: | 160kw,180kw; |

| Weight: | 14.5Ton,10ton; | name: | fdy yarn spin draw line; |

| Packaging Detail: | 2*40"GP Fully Automatic PP Industrial FDY Yarn Multifilament Yarn Spinning Machine; | Warranty: | 1 Year; |

| Place of Origin: | China; | Showroom Location: | Egypt,Viet Nam,Saudi Arabia,India,Argentina; |

| Product: | Lace,webbing ,belt ,rope .; | Model: | JM181; |

| Video outgoing-inspection: | Provided; |

Fully Automatic PP Industrial FDY Yarn Multifilament Yarn Spinning Machine

Advantage:

1) low power consumption,1-12kw/1kg yarn

2) Fast assemble and training ,professional engineer 1-15 days

3) Reasonable design to make high tenacity yarn above 7g/d,

4) Easy operate ,PLC control +touch screen

5) It require the building roof 7m

6) Electric parts from famous JAPAN brand

7) The multifilament used for webbing,rope,filter ,sewing thread,concrete fiber etc,

Machine picture:

Fully Automatic PP Industrial FDY Yarn Multifilament Yarn Spinning Machine

Technical :

|

Item |

JM261 |

JM241 |

JM811 |

JM161 |

JM141 |

|

Pos |

2 |

2 |

1 |

1 |

1 |

|

Fibre denier |

500-1500D(single yarn) ,above 1500D need combine |

||||

|

Spinneret/position |

6 |

4 |

8 |

6 |

4 |

|

Winder speed |

2000-2400m/min |

||||

|

Capacity (900d) |

3.5toms |

2.3tons |

2.3tons |

1.7tons |

1.2tons |

|

Screw dia |

120mm |

105mm |

90mm |

90mm |

70mm |

|

Power |

280kw |

130kw |

120kw |

150kw |

120kw |

|

Machine size |

5.5*5*6.7m |

||||

Yarn production process :

Chips→ extruder→ extruding head →melt pipe with static mixer→ spinning beam with oil heating →quenching delay→ quenching chamber → oiling system → feeding roller →migration nozzle→ four pairs of hot godet rollers→ inter lacing jets→ take-up winder →final product

The daily output calculation:

Based on 1000denier,1 winders ,4cops of each winder,

winding speed2200m/min, efficiency 96%

1000*1*4*2200*60*24*0.96

Q= -------------------------------------=1.35(ton/day)(For reference)

9000*1000*1000

Machine Part Introduce:

EXTRUDER PART:

1.automatic hopper loader

2.Extruder head (with measuring head)

3.spinning beam

4.metering pump

5.spinnneret+packs

------------------------------------------------------------------------------------------------------------------------------------------------------------

AIR COOLING BLOWER

1.blowing area:W 1250mm*H1800mm

2.With filter

3.With air fan,frequency control

4.It can be opened from the side. It's very convenient

------------------------------------------------------------------------------------------------------------------------------------------------------------

GODET ROLLER SYSTEM

1.5 Units rollers

2.Roller size:190*330mm

3.Hard chromiun plating on surface

---------------------------------------------------------------------------------------------------------------------------------------------------------

HIGH SPEED WINDING MACHINE

1.4 ends,6 ends,8 ends,12 ends

2.1600-2600m/min

3.Paper bobbin size:Φ110×Φ125×230mm

4.Max spool dia: Φ420mm ,Traverse mode

5.famous winder brand

Machine running process:

Chips→ extruder→ extruding head →melt pipe with static mixer→ spinning beam with oil heating →quenching delay→ quenching chamber → oiling system → feeding roller →migration nozzle→ four pairs of hot godet rollers→ inter lacing jets→ take-up winder →final product

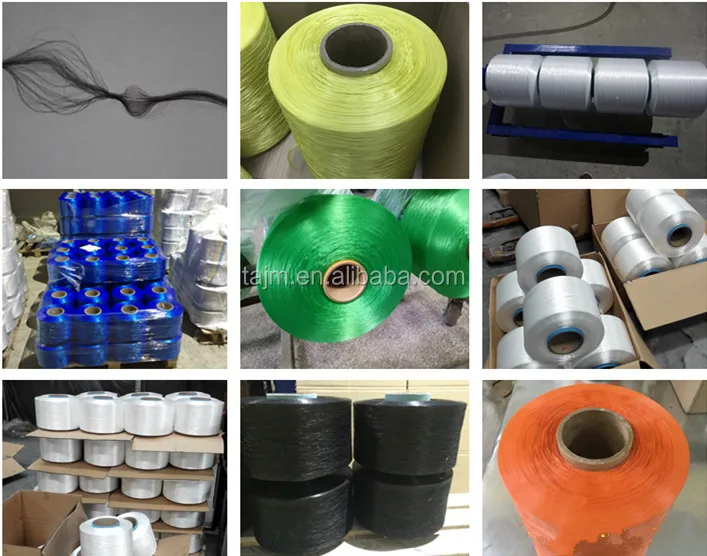

Yarn/Fibre pic :

Yarn/fiber Application:

1) Needle loom for knitting webbing and belt

2) Twisting machine for twising rope,cordage, twine

3) Braiding machine for braided rope, core-spun twisted rope for gift bag handle

4) Reinforced concrete fiber, cement building fibre

5) Sewing thread yarn for woven bag and sacks, JUMBO bag, flour bag, lifting handle, sacks, container bag etc

6)Chemical filter

Factory:

Taian Jiamei Machinery Technology Co. ,Ltd is specialized in extrusion technology machinery research ,design and manufacture . Have good experience of 30 years in machinery of extrusion technology .

Our main products include pp multifilament spinning line ,polyester multifilament spinning line , all kinds of plastic extruding machine .Our equipment is widely used in the industrial fields of braiding/knitting products ,construction reinforce fiber ,sewing thread ,rope ,narrow fabric etc .So far , many customer have gain very good economical benefits with our equipments .

Recent years , we start to develop international market , the machines have been exported to Spain, Romania, Russia ,Ukraine, India, Indonesia, Thailand, Africa etc .

Feature :

Fully Automatic PP Industrial FDY Yarn Multifilament Yarn Spinning Machine

Packing+Training:

1. Have skilled worker available come to support customer for this project , stay at customer,s factory 3-6 months .

2. Have our own yarn production factory , the customer can come and learn machine orperate at our yarn factory

3. Have two kind of drawing system for customer select , godet type and air oven type ,

4. Export to Russia ,Ukrine,European ,India etc , we have professional team including engineer

5. Convinient for testing running before delivery .

Support Facilities

Yarn Twisting machine

Vacuum furnace

Rope machine

Fiber cutting machine

Contact:

-

Thermal godet/spinning machine godet

-

GA747-III Flexible Sword Loom Simple Sword Loom No Ship To China

-

Rieter 20 2002 used starter

-

Refurbished high automatic dobby jacquard loom rapier loom loom

-

Tongda FA1569 Textile Cotton Yarn Machine Production Line Ring Spinning Machine Price

-

Large Capacity New China Silk 2-in-1 Yarn Twister Machine

-

Rieter K44 tension wheel

-

Textile Production Line Blowing Carding Machine

-

JD758B Towel bar loom

-

Home Small Loom Weaving Beginner Loom Special Loom

Other Products

-

$1450.00 / set

$1450.00 / set -

$103500.00 / set

$103500.00 / set -

$95000.00 / set

$95000.00 / set -

$92000.00 / set

$92000.00 / set -

$9950.00 / set

$9950.00 / set