JUKl overlock Sewing Machine DD Motor Auto Induction Suction&Thread Cutting Device

-

Supplier: Grand Precision Industrial Ltd. -

Region: Guangdong, China -

Contact: Mr Kimstem Wu -

Price: $350.00 /unit -

Min. Order: 1 unit

Product details

| function: | Auto Induction Suction&Thread Cutting Device for sewing; | Machinery Test Report: | Not Available; |

| Port: | zhongshan/Hongkong; | Core Components: | PLC,Motor; |

| Applicable Industries: | Garment factory; | Video outgoing-inspection: | Provided; |

| pressure: | 0.8kpa; | Automatic Grade: | Semi-automatic; |

| Marketing Type: | Hot Product 2019; | Certification: | ISO9001:2008; |

| name: | Auto Induction Suction&Thread Cutting Device; | Payment Terms: | L/C,T/T; |

| Voltage: | 220v,220V; | Packaging Detail: | Carton Packaging, About 8~10kg sets; |

| Place of Origin: | Guangdong China; | After-sales Service Provided: | Video technical support,Online support; |

| After Warranty Service: | Video technical support,Online support,Spare parts; | Condition: | New; |

| Local Service Location: | None; | Showroom Location: | None; |

| Warranty of core components: | 1 Year; | model: | GMD1-GTC-8-JUKI; |

| Supply Ability: | 500 Unit/Units per Week; | Brand Name: | GRAND; |

| Warranty: | 1 Year; |

GTC Series Microcomputer Direct Drive Motor Automatic Induction Suction Thread Cutting Device (For Overlock Sewing Machine, Patent Product, Special Design):

Mainly equipped with "pneumatic thread cutter group + direct drive motor and control system" integrated into "automatic presser foot lift, front and rear suction tangent dust collection" microcomputer intelligent new automation product, operation is simpler and easier to use, the focus is on its installation " "Compatibility" is very strong, all kinds of domestic and foreign brands of old and new overlock sewing machines can be installed, more convenient, more intuitive, wider range, facing the new trend of the future development of industrial sewing technology.

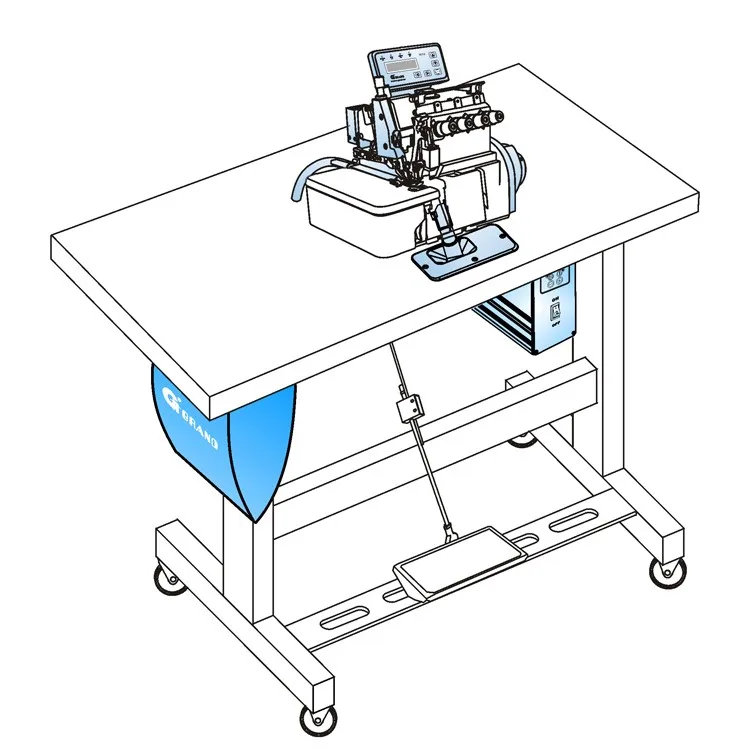

GMD1-GTC-8-P-JUKI Direct-drive motor automatic induction suction wire cutting device (direct-drive motor + two or three pairs of radio eyes + pneumatic thread cutter group + presser foot + air suction dust collection device, with JUKI Overlock sewing machine series) Product pictures are as follows, for reference only:

The schematic diagram of component installation is as follows:

|

Product name: |

Microcomputer direct drive motor automatic induction suction thread trimming device (direct drive motor + two or three pairs of radio-sensors + pneumatic thread cutter group + presser foot + air suction dust collection device, with JUKI heavy machine overlock sewing machine series) |

| Product model: | GMD1-GTC-8-P-JUKI |

| Features: |

1.Using servo direct drive motor and control system, super power saving;

2. Electric eye sensor, which can automatically lift the presser foot to run and sew to achieve time-saving effect;

3. Electric eye sensor, which can set the number of stitches to control the automatic stop of sewing suction and thread trimming to save money;

4. Inductive induction, the number of stitches can be set to control the two sections of automatic suction before and after sewing to achieve air-saving effect;

5. Use reflective electric eye with pneumatic cutter group, fixed knife can adjust the angle to extend the life of the cutter body; cutting and cutting can be used at the same time, maintenance-free;

6. No need for skilled employees, let new and old employees stand on the same starting line.

7, save time, materials, labor, comprehensive production capacity increased by about 30%.

8. This product is suitable for heavy machine, Yamato, Pegasus, Yinjian and domestic overlock sewing machines.

9. If there are special circumstances, please contact the engineering department directly.

|

Compared with similar KS \ KH products, this product has many advantages:

| GTC series thread cutting device | KS KH thread cutting device | |

| 1 | With button type manual thread trimming function, it is easy to use in special cases | without manual thread trimming function |

| 2 | Front stitch can be cut | Can't cut front suture |

| 3 | No need to stop the cutting suture, can increase the output by 30% | Must stop the cutting suture |

| 4 | Back cut stitching length can be selected | Back cut stitching cannot be selected in length |

| 5 | Consistent stitch length after cutting to improve product quality | Uneven stitch length after cutting |

| 6 | Can cut elastic bands, shoulder straps, etc. | Elastic bands, shoulder straps, etc. cannot be cut |

| 7 | Single process sewing can save 16CM line | Can't save line |

| 8 | Suction air only at the moment of tangent, saving energy and reducing noise | Always sucking air while sewing |

| 9 | Even newbies can operate | Must be skilled |

It is suitable for the sewing operation of pants, pajamas, sportswear, work clothes, blouses and handkerchiefs.

Factory instance :

VIEW MORE

You may like

-

Manufacturer Britex BR-GT880D direct drive 3 4 5 line brand new industrial overlock sewing machine

-

Hot selling Britex 747 high speed four 4 thread overlock sewing machine industrial overlock sewing machine

-

Industrial 4-wire high-speed automatic overlock sewing machine

-

RONMACK Automatic Overlock Sewing Machine Cylindrical Bed Sleeve Cuff Pants Leg Automatic Sticking Knitted Fabric Garment Sewing Machine

-

Jack C4 Automatic Overlock Sewing Machine Wholesale Price

-

Hot sale carpet overlock sewing machine desktop household overlock sewing machine

-

FEIYUE YAMATA overlock sewing machine fully automatic computer intelligent overlock sewing machine

-

BT 703 Home Mini Overlock Sewing Machine Home Max Marketing Motor Power Technical Parts Sales Video Weight

-

OVERLOCK SEWING MACHINE

-

FN2-4D-B Mini Overlock Sewing Machine

Other Products

-

$180.00 / unit

$180.00 / unit -

$80.00 - $90.00 / unit

$80.00 - $90.00 / unit -

Related Search

overlock sewing machines

juki overlock sewing machine

overlock sewing machine view as

industrial sewing machine clutch motor

crochet stitch overlock sew machin suppliers

700d overlock sewing machine

servo motor for sewing machine

sewing machine motor

sewing machine industrial overlock

3 4 thread sewing machine overlock