Metal Foundry Custom Made cast iron steel valve body parts by Investment casting

-

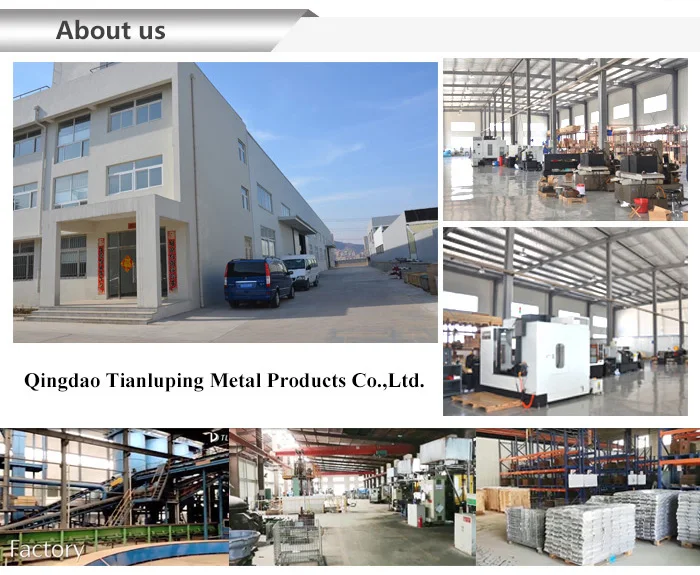

Supplier: Qingdao Tianluping Metal Products Co., Ltd. -

Region: Shandong, China -

Contact: Mr Eric Lu -

Price: $0.60 / >=500 pieces -

Min. Order: 500 pieces

| Process: | Precision Casting; | Certificate: | ISO9001; |

| Brand Name: | TLL(or OEM brand); | Port: | Qingdao; |

| Model Number: | TLL-ZL; | Body material: | 316LStainless steel; |

| Payment Terms: | T/T; | Delivery: | 30~45 Days; |

| Service: | OEM Custom Fabrication; | MOQ for mass production: | 500PCS; |

| Dimension: | Customer's Drawings casting parts; | Supply Ability: | 1500 Piece/Pieces per Month; |

| Package Preview: | ; | Type: | Valve Bodies; |

| Packaging Detail: | 1. plastic bags 2. wooden cartons 3. pallet or packed as requirement; | Application: | Industry; |

| Color: | Customer's Requirement; | Packing: | Customers' Request; |

| Place of Origin: | Shandong China; |

| Item | Description |

| Service | OEM / ODM or Sample Production |

| Process Technology | lost wax casting process / soluble glass casting process / silicasol casting process/ die casting process /sand casting process / + Precision CNC Machining + Surface Treatment |

| Material we can cast | (1)grey iron, ductile iron , pig iron |

| (2)carbon steel, stainless steel, alloy steel | |

| (3)aluminum alloy, aluminium, A380, aluminum 6061 | |

| (4)zinc alloy ,copper, brass, bronze etc | |

| Size | Customized as customer's drawings |

| Weight Range | 0.02-50 KGS |

| MOQ | 500 Pieces |

| Tolerance | ±0.02mm |

| Surface Treatment | Heat Treatment, Polishing, Plating, Machining, Anodizing, shot, sand blasting, zinc plated, oxide, galvanized etc. |

| Testing | Three coordinate measurement machine for testing. |

| Certification | ISO9001:2008 |

| Standard | ISO , DIN, AISI, ASTM, BS, JIS, etc. |

OEM Material We manufacturer :

| Process Techonology | Material |

| Investment casting |

ASTMA148class80-40, ASTMA148Class80-50 A572GR60, AISI316 stainless steel, ST52, S355, GS-52.3, ASTMA48Class30B CK45, 1.7218-25CrMo4 |

| Sand casting |

GGG50,GGG30, ASTMA48 class25B, 42CrMo4, C22 ductile iron 65-45-12, AlCuMgpbF34, EN-JIS-500-7 EN1563 , EN10293-GE300 HT200, DIN17205-GS-25CrMo4 |

| Die casting |

C1040, A356, A380,AISI12 |

| Stamping Parts |

Steel , alloy , Aluminum or as above |

| Forging |

Steel , alloy , Aluminum ,Zinc , Copper , Brass ,or other as above |

| CNC Machining | Steel , alloy , Aluminum ,Zinc , Copper , Brass ,or other as above |

Engaged in the casting industry for 12 years, our foundry has built up the complete production lines and quality control systems. We supply OEM service and exports to Germany, Japan, USA, Canada, Korea, New Zealand, and so on.

OEM /ODM Custom Service |

SGS / TUV / ISO 9001:2015 Certified |

Over 12 Years' Casting Experience |

Clients in over 20 countries cooperate with us |

Our main products line includes die casting, sand casting, precision casting, stamping, forging, CNC turning and so on. Materials vary from grey iron, ductile iron, bronze, aluminum, steel, stainless steel, and so on.

Application:

1. Food Machine Hardware

Components of liquid food equipment

Tapping device for beer, milk and juice dispensers

Handles for pot, spoon and fork

2. Machine Hardware

Safety Locker Quick Coupling

Clip Pipe and Fitting

Other mechanical hardware

3. Pumps&Valves

4. Marine Hardware

5. Building Hardware

6. Mine, Oil, Textile Mechanical Parts

Component for mine equipments

Component for agricultural and textile machinery

Parts for hydraulic and air compressing equipment

FAQ:

1 . How to contact with your company?

Please send email to us or chat on line

2 .What does your company need to submit a quotation?

Drawing or sample, together with relevant information, such as quantity, weight, material.

3. Which kind of format of the drawing?

PDF, IGS, DWG, STEP, etc

4 . What if we do not have a drawing?

We can duplicate your sample and make drawing for your confirmation.

5. How soon before I get a sample?

weeks for mold and sample, 3-7 days for express.

6. How can we quote for you?

As our factory only supply OEM service(custom service)

Please send us enquiry by email, with all the technical drawings you have, with all of your requirements,

such as material grade, tolerance, machining demands, surface treatment, heat treatment, mechanical property requirements, etc. Our specialized engineer will check and quote for you, we would appreciate the opportunity and will respond in 3-5 working days or less.

It is also best if you can provide a sample, we can also quote depends on the sample.

-

Quick Connect Soda Club Terra DUO Art to External Co2 Tank Adapter 1.5m Hose Kit W21.8-14 or CGA320 with Pressure Gauge Quick Disconnect

-

ATOS solenoid valve SDHE-0714 10S SDHE-0718 10S SDHE-0713

-

DN50 electric ball valve high durable anti-corrosion UPVC plastic valve body 1 year Junzhou CN;ZHE ODM

-

High-quality stainless steel angle valve body Chrome-plated valve body Brushed valve body

-

GLOCK P1 SI Coiled Outer Tube Glock Metal Threaded Outer Tube 14mm Toy CCW

-

New Design Gas Valve LPG NG Butane Aluminum Valve Propane Grill Valve and Hose

-

Replaces Robertshaw Combination American 1/2 Psi Valve

-

Amazon Hot Sale New M18*1.5 Paintball Filling Station Paintball pcp Air Gun Tank Charging Valve Double Gauge with 50cm Hose

-

Manufacturer Sell High Quality 1-1/2 Inch DN40 Two Way Brass Electric Ball Valve

-

Factory Supply Grill Gas Stove Spare Parts Control Valve

Other Products

-

$1.20 - $1.80 / piece

$1.20 - $1.80 / piece -

$21.00 / piece

$21.00 / piece -

$4.00 / piece

$4.00 / piece -

$1.99 / piece

$1.99 / piece -

$1.00 / piece

$1.00 / piece -

$1.00 / piece

$1.00 / piece -

$10.00 / piece

$10.00 / piece -

$2.30 / piece

$2.30 / piece -

$0.50 / piece

$0.50 / piece -

$2.00 / piece

$2.00 / piece