wire straightening and cutting machine straightening and cutting machine

-

Supplier: Shandong Feihong Engineering Machinery Co., Ltd. -

Region: Shandong, China -

Contact: Ms Jianmei Jia -

Price: $9900.00 /set -

Min. Order: 1 set

| Marketing Type: | New Product 2020; | Supply Ability: | 60 Set/Sets per Month; |

| Payment Terms: | L/C,D/P,D/A,T/T; | Warranty: | 1 Year; |

| Weight: | 5 tons; | Wire Sizing Cutting Error(mm): | ≤1mm; |

| ITEM NAME: | Steel coil straightening and cutting machine; | Key Selling Points: | Competitive Price; |

| Control System: | CNC Controller; | Voltage: | 380 v; |

| Power: | 24KW; | Wire Straightening Diameter 2: | Round Steel3-7mm; |

| Brand Name: | Feihong; | Certification: | CE; |

| After-sales Service Provided: | Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Video technical support,Online support; | Wire Straightening Diameter: | Screw-Thread Steel 3-7mm; |

| Package Preview: | ; | Machinery Test Report: | Provided; |

| Use: | Wire; | Applicable Industries: | Building Material Shops,Construction works ; |

| Video outgoing-inspection: | Provided; | Port: | QingDao; |

| Core Components: | PLC,Engine,Motor; | Showroom Location: | Canada,United Kingdom,Russia,Sri Lanka; |

| Warranty of core components: | 1 Year; | Type: | Straightener & Cutter; |

| Packaging Detail: | Steel coil straightening and cutting machine will be nude packed in container, the parts and tool will be packed in wooden case. Machine is suitable for long distance sea shipment.; | Dimension(L*W*H): | 000x1300x1100mm; |

| Local Service Location: | Canada,United Kingdom,Russia,Sri Lanka; | Place of Origin: | Shandong China; |

| After Warranty Service: | Video technical support; | Wire Cutting Sizing(mm): | Infinitely adjustable; |

| Condition: | New; |

SIEMENS PLC rebar steel wire straightening and cutting machine

Steel wire straightening and cutting machine Siemens CNC control system straightened & cut wire machine is positioned in the high-end market within the industry. The technical aspects refer to the development of international advanced models in the late 1990s. Up to now, there are six standard models available, and they are supplied in bulk. Suitable for 3-16mm glossy coil reinforcement. Cold rolled ribbed steel bars, Hot-rolled ribbed steel coil straightening and length cut off

Technical Parameters – – Steel Coil Straightening and Cutting Machine

Technical Parameters – – Steel Coil Straightening and Cutting Machine

| Model | FHT3-7 |

| Wire Diameter | φ3-φ7mm for HRB335 hot rolled ribbed Class Ⅱ Disc deformed steel bar φ3-φ7mm HRB400 hot rolled ribbed Class Ⅲ Disc deformed steel bars |

| Cutting Speed | 70-100-130 |

| Cut to lenght tolerance | +-1mm |

| Total rated power | 45+4KW |

| Coil pay-off | 1 set |

| Straightening Unit | 1 set Horiaental gun-stand |

| Cutting Unit | 1 set Straightening Roller, made of excellent wear-resisiting ,Alloy Steel,can straighten two wire at the same time .Perfect surface quality and uniform characterisitics. |

| Discharge and Collect Unit | 1 set Special Hydraulic Unit ,Accurate length |

| Discharge and Collect Unit | 1 set 12m in length |

| Control System | 1 set PLC from Germany |

| Spare parts and tools | freely |

Features of automatic Steel Coil Straightening and Cutting Machine

1) The equipment is controlled by Siemens CNC system, which automatically straightens, cuts and stores the steel bars (round steel, rebar).

2) The cut steel bars can be automatically aligned, saving time and effort, advanced storage setting, buffering and receiving mechanism, and no need to stop when packing.

3) The straightening process and the conveying mechanism are controlled by numerical control system, which can be steplessly regulated; the straightening speed is fast, (straightening speed can reach 136m/min), the straightness is high, and the safety is high.

4) The operator can conveniently operate two straightening machines in both forward and reverse directions, and the production efficiency is doubled. The equipment has a small footprint, moderate weight, easy assembly and disassembly, and convenient transportation.

5) Simultaneous input of length and quantity in multiple batches, computer storage and memory, efficient and convenient.

6) The unloading rack is made fine, the length of the steel bar can be read directly from the scale, and the adjustment is simple.

7) The main machine adopts servo motor cutting technology, synchronous belt transmission, accurate positioning and no noise.

8) The smallest steel bar with a minimum shear of 1000mm is stable and maintenance-free.

Shandong Feihong is a leading numerical control steel processing equipment manfacturer, which designs and provides practical automatic numericalcontrol steel processing services program for the steel processing field and construction site in the field of highway, high-speed railway and housing construction in over 20 countries and areas around the world to have the global customer enjoy steel automatic processing services with ultra-highquality and professional design unique

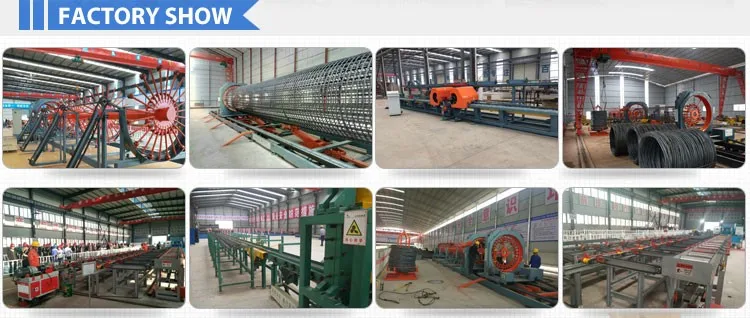

Welcome to our factory

Our Honor and Certificate

Packing & Delivery Time

Packing

Straightening and Cutting Machine will be nude packed in container, the parts and tool will be packed in wooden case.suitable for long distance sea shipment.

Delivery Time

25-30 days after received the down payment.

Related Product

Our Service

♦Pre-sale Service

Quality & Price is built on each transaction's satisfaction

Customized Design Reasonable Equipment based on your request,our team's hard research & existing project proposal

♦Sale Service

Strict QC Inspection---8-Level Quality Assurance System off the production line

Details & Video Sent to help your workers know how the device works

OEM&ODM Service with Professional R&D and Design Team

♦After-Sales Service

Maintenance Response in 24 hours After-Sales Service Team

Oversea Technical Support Experience

Customer Reviews Satisfaction is nearly 100%

FAQ

1. Q: Are you a factory or trading company?

A: We are a professional manufacturer with strong capability in research, development and manufacturing, you can not only get the factory price but also can enjoy the “ultra-high quality and professional design” unique to Feihong.

2. Q: Where is your factory located? How can I visit there?

A: Our factory is located in Jining City, Shandong Province, China. We have branch Office in Qingdao sea port city, which is very convenient for shipment.

All the customers, from home or abroad, are warmly welcome to visit us!

3. Q: Can you do OEM?

A: Yes, we can do OEM as client’s requirement.

4.Q: All products have a warranty?

A:YES, Our warranty term is One Year.

5.Q:What about the delivery time?

A:Usually 15-30 days after down payment, the exact delivery time is according to the production season and order quantity.

6. Q: What is the biggest advantage of the company??

A: Stable Better Quality and Perfect Service .

Our company is a state high-tech enterprise, our rebar processing machinery are used in hundreds of infrastructure projects both with China and abroad. We are the framework agreement supplier to CREC(CHINA RAILWAY ENGINEERING CORPORATION).

We have the most complete after-sales service support system ,"8-level quality assurance system," truly lifelong maintenance, customer satisfaction is almost 100%.

Contact us

-

Fast Wire Machine Straightener and Cutter 2-5mm Wire Straightener

-

HWASHI Drum Wire Straightening and Cutting Machine

-

Steel pipe straightening, derusting and painting multifunctional all-in-one machine

-

0-65m 9+4 13KW large-scale frequency conversion CNC steel bar metal straightening and cutting machine

-

AF-2C Industrial Automatic Feeder Pneumatic Feeder

-

China supplier automatic steel coil bar straightening and cutting machine CNC double wire straightening machine lowest price

-

Automatic steel wire coil straightening and cutting machine stainless steel straightening and cutting machine

-

LE3-6 wire straightening and cutting machine automatic wire straightening and cutting machine

-

Steel coil automatic uncoiler hydraulic decoiler and feeder strip decoiler 10 ton decoiler

-

High efficiency GT4-12 steel wire routing and cutting machine

Other Products

-

$4000.00 / set

$4000.00 / set