200 kg / h recycled plastic PE PP PS resins making machine

-

Supplier: Jiangsu Aceretech Machinery Co., Ltd. -

Region: Jiangsu, China -

Contact: Mr Kelvin Bian -

Price: $20000.00 / 1 - 9999 sets

$2000.00 / >=10000 sets -

Min. Order: 1 set

Product details

| Package Preview: | ; | Condition: | New; |

| Packaging Detail: | Bubble film, stretch film, pallet 200 kg / h recycled plastic PE PP PS resins making machine; | Local Service Location: | None; |

| Brand Name: | ACERETECH; | Name: | 200 kg / h recycled plastic PE PP PS resins making machine; |

| Automatic weighing: | Optional; | After Warranty Service: | Video technical support,Online support,Spare parts; |

| Key Selling Points: | Long Service Life; | Remote monitoring: | Optional; |

| Supply Ability: | 100 Set/Sets per Year; | Machinery Test Report: | Provided; |

| After-sales Service Provided: | Video technical support,Online support; | Plastic Type: | Bopp,PE,PP/PE,EPS,PP,ABS,PS; |

| Filter: | Plate, Piston, Self-cleaning; | Payment Terms: | L/C,Western Union,T/T; |

| Place of Origin: | Jiangsu China; | Automatic packing: | Optional; |

| Marketing Type: | Hot Product 2019; | Core Components: | PLC,Gearbox,Motor; |

| Warranty: | 1 Year; | Applicable Industries: | Manufacturing Plant; |

| Recycle: | PE PP PS; | Video outgoing-inspection: | Provided; |

| Mother-baby double extruders: | Optional; | Pelletizing way: | Water-ring, Strand, Underwater; |

| key word: | recycled plastic machine; | Port: | SHANGHAI; |

| Showroom Location: | None; | Warranty of core components: | 1 Year; |

| Screw: | Bi-metal, 2 years guarantee.; |

200 Kg / H Recycled Plastic PE PP PS Resins Making Machine

Product Description

The acs series compacting and pelletizing system combines function of crushing, compacting, plasticization and pelletizing to one step.applied in the plastics recycling and pelletizing process. ACS system is a reliable and efficiency solution for plastics films, raffias, filaments, bags, woven bags and foaming materials re-pelletizing.

Final productions produced by acs system are in the form of pellets/ granules, can directly put into the production line for film blowing, pipe extrusion and plastics injection, etc.

Final productions produced by acs system are in the form of pellets/ granules, can directly put into the production line for film blowing, pipe extrusion and plastics injection, etc.

Tips:

1. All prices and parameters shown above are automatically generated by the system, if you want to know the exact information, please click "Send Inquiry" to contact us.

2. Because of the time difference, we suggest that you can choose "Send Inquiry" instead of "Chat Now"

3. When sending us an inquiry or message, Please tell us your usual contact information, then our sales manager can contact you quickly.

Aceretech Recyclable Plastics Include:

* LLDPE/LDPE/HDPE/PE/EPE film, crushed material, lithium battery film, foamed pearl cotton

* PP/OPP/BOPP/CPP film, woven bag,

non-woven fabric (melt blown)

* PA66 fishing net, silk, factory trim, carpet

* PET/BOPET bottle flakes, film, silk, waste cloth, foam,optical film

* PTT wire

* EPS/XPS crushed material, cold briquetting foam, hot melt foam, insulation board

* HIPS/PC/ABS home appliance housing, electronic waste, factory plastic

* PVB crushed material, flakes

* PU

Suitable Products

Final Products

Product Paramenters

SPECIFICATIONS | ||

Machine Model | ACS | |

Target Recycled Material | HDPE, LDPE, PP, BOPP, CPP, OPP, PA, PC, PS, PU, ABS | |

Final Product Shape | Particles | |

System composition | Belt Conveyor, Cutting Compactor, Single Screw Extruder, Filtration, Pelletizer, Water Cooling Device, Dehydration Section, Conveyor Fan, Product Silo. | |

Output Range | 150kg/h-1200kg/h | |

Feeding Device | Belt Conveyor (Standard), Roll Hauling off device (Optional) | |

Compactor Volume | 300L-1400L | |

Diameter of screw | 80mm-180mm (Standard) | |

Material of screw | 38CrMoAlA (SACM-645), Bimetal (Optional) | |

L/D of screw | 31/1, 32/1, 34/1, 36/1 (According to the characteristics of recycling) | |

Heater of barrel | Ceramic heater or Far-infrared heater | |

Cooling of Barrel | Air cooling of fans through blowers | |

Vacuum deashing exhaust | Two Double-zone vacuum degassing system (Standard) | |

Pelletizing type | Water-ring pelletizing/ water-strands pelletizing/ Under-water pelletizing | |

Voltage Standard | According to the Voltage of the Customer's Location | |

Optioanl device | Metal detector, Roll hualing off device, Masterbatch and additives feeder | |

Warranty | 13 months from the date of bill of lading | |

Technical services | project design, factory construction, installation and recommendations, commissioning | |

Model | Screw Diameter (mm) | L/D | Extruder motor (kw) | Output capacity (kg/h) |

ACS-H300/80 | 80 | 36 | AC 55 | 160-220 |

ACS-H500/100 | 100 | 36 | AC 110 | 300-380 |

ACS-H800/120 | 120 | 36 | AC 132 | 450-480 |

ACS-H1000/140 | 140 | 36 | AC 185 | 500-650 |

ACS-H1200/160 | 160 | 36 | AC 250 | 800-1000 |

ACS-H1400/180 | 180 | 36 | AC 315 | 1000-1200 |

Product Detail

Feeding

Motor drives of conveyor belt and hauling device cooperate with abb inverter. feeding speed of conveyor belt or roll hauling off

is fully automatic based on how full the compactor’s room is. metal detector can be combined with belt conveyor and can interlock

with control system, to warn and stop the system, in case that metal is found in feeding section.

Sliding Gate With Servo Motor

It can handle both hard and soft materials. The sliding gate controls the residence time of the material in the compactor to achieve the effect of pre-drying and ensure that clean and dry material enters the barrel. Material that fails to achieve the treatment effect will not be able to enter the next process. PLC accurately controls the quantity of forced feeding materials to ensure production capacity.

Intelligent Control

Intelligence Start: One button only Following set logistical sequence and materials processing requirement, interlocked system modules can start by "one button only”

Intelligence Stop: One button only Each related modular part in ACS system available to shut down by only one button.

Emergency Stop Emergency stop function is available in ACS system in case that uncertain risk occurred during machine running.

Remote Monitoring And Information Transmission

System program remote monitoring and transmission system,bluetooth both are available for ACS-Pro system realizing functions of remote monitoring and information transmission.

Single Screw Extruder

By screw’s rotation, the plastic material goes forward, to finish the processing of compacting, melting, homogenization. Material of screw adopts qualified nitride steel(38CrMoAlA), process of CNC, with nitride treatment, has the ability of corrosion

resistance and wear-resisting. With the specialized design of screw, even running with high speed, the material of polyolefin can

be well melted under lower temperature and lower melting pressure.

resistance and wear-resisting. With the specialized design of screw, even running with high speed, the material of polyolefin can

be well melted under lower temperature and lower melting pressure.

Barrel

It is part of screw pair, made of nitride steel, inner surface with nitriding treatment, to present higher surface hardness and better wear-resisting. The hot energy generated by heaters transmits through the barrel to the inside plastic materials, makes the plastic melting; with the temperature sensors and cooling fans which assembled on each heating zone.

Vacuum Degassing

Its function is to remove the low molecule and remain moisture from the melts which happened during the plastic raw material

melting.

The vacuum degassing system consists of vacuum pump, vacuum room, filtering tank, pressure guage and pipelines. Vacuum pump is water ring type, forms the high negative pressure by the water sealing, suitable to waste gas and water enforcingly separate.

melting.

The vacuum degassing system consists of vacuum pump, vacuum room, filtering tank, pressure guage and pipelines. Vacuum pump is water ring type, forms the high negative pressure by the water sealing, suitable to waste gas and water enforcingly separate.

Plasticization And Degassing

A specialized single screw extruder applied to gently melt the pre-compacted material. the plastic scraps will be well melted, plasticized in a 34d to 36d processing section. with double-zone vacuum degassing system, volatiles such as low molecular and moisture will be removed efficiency, especially suitable to heavy printed film and material with water content.

2 In 1 Option

This model combines our self-developed self-cleaning filter.The new SCF self-cleaning filtration system makes non-stopping recycling extrusion, especially suitable to highly contaminated materials re-pelletizing. SCF filtration system can handle and remove up to 5% contaminates in the melt flowing, can separate the contaminates as: paper, wood, aluminum, unmelted plastic and rubbers etc.

Melt Filtration

A regular single-plate/ piston double-station screen changer or non-stop double-plate/ piston four-station can be installed on head of extruder to present significant filtration performance. the requirements on the filter echnology depend heavily on the quality of the input material as well as the planned use of granules.

Pelletizing

Water ring pelletizing system set as the standard granulating method. self-adjusting pelletizing head for the best granulate

quality and long uptime thanks to consistently correct blades pressure. The production line can be equipped with three kinds of granulation methods: water circumferential cutting, water-cooled stretching, automatic stretching or underwater granulation.

quality and long uptime thanks to consistently correct blades pressure. The production line can be equipped with three kinds of granulation methods: water circumferential cutting, water-cooled stretching, automatic stretching or underwater granulation.

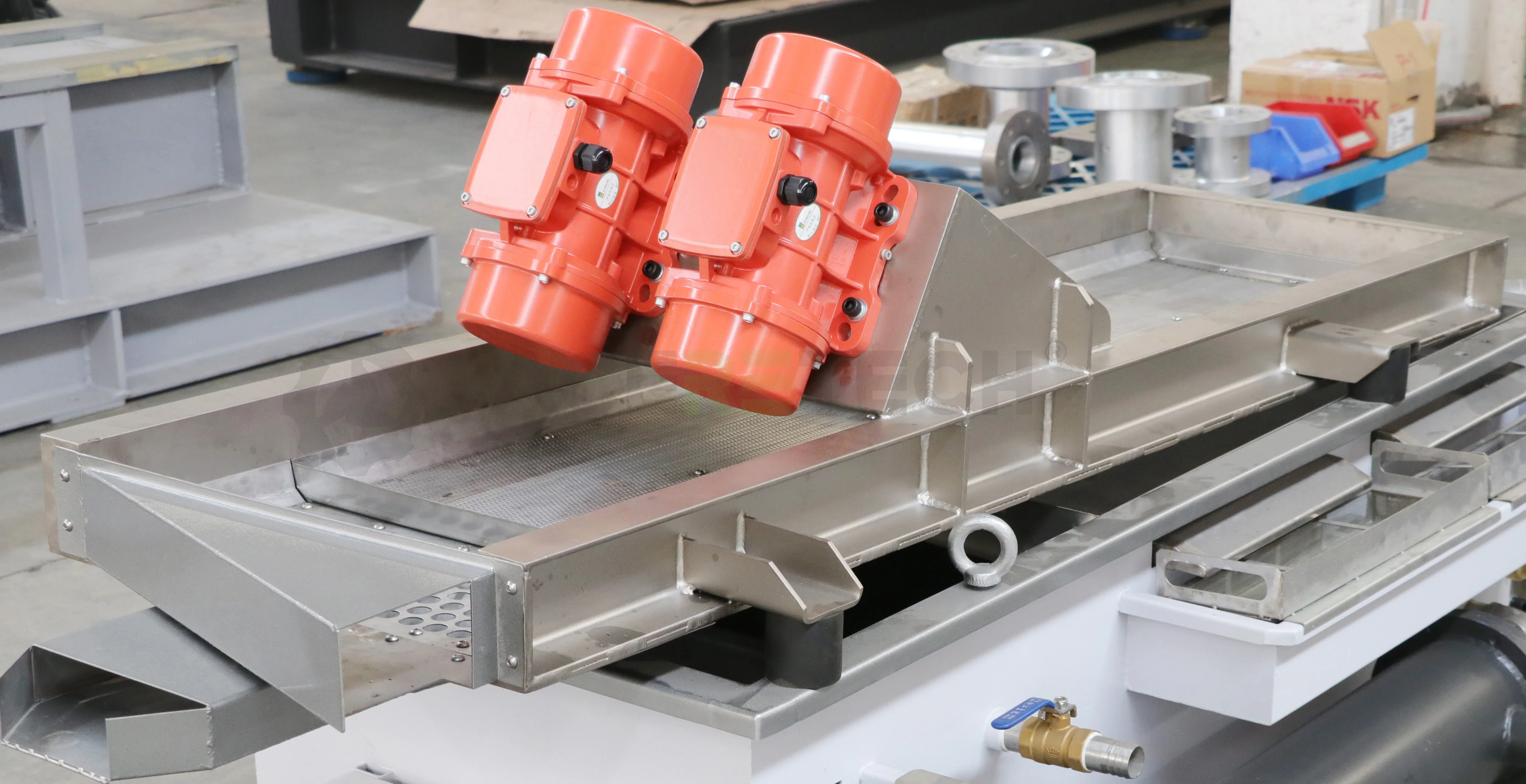

Vibration Dry And Packing System

Advanced dewatering vibration sieve combining with horizontal- type centrifugal dewatering present high-performance dried pellets and lower energy consumption.

Production Silo

Storage in the production silo.

Plastic Granules

Final output: Plastic granules

IF YOU WOULD LIKE TO KNOW MORE INFORMATION ABOUT US, PLEASE DO NOT HESITATE TO

CONTACT US

Our Company

FAQ

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME

● ACERETECH is original manufacturer.

● If you interested in our products and we can fulfill your request , you may pay a visit to ACERETECH Factory.

● The meaning of visiting supplier, since seeing is believing, ACERETECH Machinery with own manufacture and developed& research team, we can send you engineers and make sure the high efficiency after-sales service.

SEE ACERETECH MACHINE HOW TO ENSURE THE QUALITY

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strict control by inspecting personnel.

● Each assembly is in charge by a master who has working experience for more than 15 years

● After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory

THE AFTER-SALE SERVICE OF ACERETECH MACHINERY

● After finishing the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools.

● After the commissioning, we will package the equipment by the standard export package for shipment.

●According to the customer's request, we can arrange our engineers to customers' factories to do the installation and training.

● Engineers, sales managers, and after-sales service managers will form an after-sales team, online and offline, to follow the customers' project.

IF YOU WOULD LIKE TO KNOW MORE INFORMATION ABOUT US, PLEASE DO NOT HESITATE TO CONTACT WITH US.

● ACERETECH is original manufacturer.

● If you interested in our products and we can fulfill your request , you may pay a visit to ACERETECH Factory.

● The meaning of visiting supplier, since seeing is believing, ACERETECH Machinery with own manufacture and developed& research team, we can send you engineers and make sure the high efficiency after-sales service.

SEE ACERETECH MACHINE HOW TO ENSURE THE QUALITY

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strict control by inspecting personnel.

● Each assembly is in charge by a master who has working experience for more than 15 years

● After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory

THE AFTER-SALE SERVICE OF ACERETECH MACHINERY

● After finishing the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools.

● After the commissioning, we will package the equipment by the standard export package for shipment.

●According to the customer's request, we can arrange our engineers to customers' factories to do the installation and training.

● Engineers, sales managers, and after-sales service managers will form an after-sales team, online and offline, to follow the customers' project.

IF YOU WOULD LIKE TO KNOW MORE INFORMATION ABOUT US, PLEASE DO NOT HESITATE TO CONTACT WITH US.

FAQ

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME

● ACERETECH is original manufacturer.

● If you interested in our products and we can fulfill your request , you may pay a visit to ACERETECH Factory.

● The meaning of visiting supplier, since seeing is believing, ACERETECH Machinery with own manufacture and developed& research team, we can send you engineers and make sure the high efficiency after-sales service.

SEE ACERETECH MACHINE HOW TO ENSURE THE QUALITY

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strict control by inspecting personnel.

● Each assembly is in charge by a master who has working experience for more than 15 years

● After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory

THE AFTER-SALE SERVICE OF ACERETECH MACHINERY

● After finishing the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools.

● After the commissioning, we will package the equipment by the standard export package for shipment.

●According to the customer's request, we can arrange our engineers to customers' factories to do the installation and training.

● Engineers, sales managers, and after-sales service managers will form an after-sales team, online and offline, to follow the customers' project.

● ACERETECH is original manufacturer.

● If you interested in our products and we can fulfill your request , you may pay a visit to ACERETECH Factory.

● The meaning of visiting supplier, since seeing is believing, ACERETECH Machinery with own manufacture and developed& research team, we can send you engineers and make sure the high efficiency after-sales service.

SEE ACERETECH MACHINE HOW TO ENSURE THE QUALITY

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strict control by inspecting personnel.

● Each assembly is in charge by a master who has working experience for more than 15 years

● After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory

THE AFTER-SALE SERVICE OF ACERETECH MACHINERY

● After finishing the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools.

● After the commissioning, we will package the equipment by the standard export package for shipment.

●According to the customer's request, we can arrange our engineers to customers' factories to do the installation and training.

● Engineers, sales managers, and after-sales service managers will form an after-sales team, online and offline, to follow the customers' project.

IF YOU WOULD LIKE TO KNOW MORE INFORMATION ABOUT US, PLEASE DO NOT HESITATE TO CONTACT US

VIEW MORE

You may like

-

Unvulcanized Steel Cord Scrap Rubber Steel Wire Separator

-

Tire recycling plant for waste recycling equipment

-

Semi-automatic waste tire recycling into rubber powder machine tire cutting machine

-

High-performance used tire recycled rubber production line rubber powder making machine tire recycling production line

-

Reclaimed rubber production equipment

-

Used tire cutting machinery, tire recycling machinery for sale

-

Factory sale 1-2 tons waste tire rubber shredder recycling plant

-

Waste tire wire separator/tire wire remover/tire wire remover

-

Zero consumption tire doubling machine used tire doubling machine for sale

-

waste tire recycling machine used tire recycling shredder factory in pakistan

Other Products

-

$140000.00 / set

$140000.00 / set

Related Search

manual ps cup making machine suppliers

non woven pp shopping bag making machine

pe pp plastic pelletizing machinery

recycled plastic material

recycling plastic uk

pp pe making machine

full auto recycl plastic to oil suppliers

recycling plastic oil machines

waste recycling plastic plant

used recycling plastic