Manufacturer of vacuum hopper plastic material autoloader fo

-

Supplier: Zhangjiagang Wolter Machinery Co., Ltd. -

Region: Jiangsu, China -

Contact: Ms Sophia Grace -

Price: $1.00 /set -

Min. Order: 1 set

| Supply Ability: | 200 Set/Sets per Month; | Payment Terms: | T/T; |

| After-sales Service Provided: | Free spare parts; | Place of Origin: | China (Mainland); |

| Other models: | separated 1.3kw 1.5kw 2.2kw 3kw 4kw 5.5kw 7.5kw 11.5kw 12kw and higher; | Warranty: | 1 Year; |

| Usage: | injection molding machine/ blowing molding machine etc.; | Power(W): | 1.1kw; |

| Weight: | 15KG; | Keywords: | plastic vacuum autoloader, plastic feeder, vacuum hopper loader; |

| Port: | Shanghai; | Automatic dust removing: | yes, air-sweeping; |

| Brand Name: | WOLTER; | Blower type: | Carbon brush; |

| Hopper capacity: | 7.5L; | Condition: | New; |

| Blower brand: | AMETEK; | Loading capacity: | 250kg/hr; |

| After-sales Service Provided: | Engineers available to service machinery overseas; | Certification: | ISO9001; |

| Voltage: | customized (single phase); | Application: | Plastic Material Loading; |

| Packaging Detail: | (Manufacturer of vaccum hopper plastic material auto loader) wooden case packing size: 400*400*660 mm / set.; | Structure style: | self-contained hopper loader; |

| Dimension(L*W*H): | 335x345x595; |

plastic material auto loader

1. Manufacture

2. Wholesale / Retailed

3. Quality warranty

4. Easy operate

5. Different models

"WOLTER" brand vacuum feeding machine widely used in injection molding machines, extrusion machines and other raw materials transport industry. As the auxiliary equipment realizing full-automation processing, featured with convenient installation, easy operating, long distance transmission and stable production.

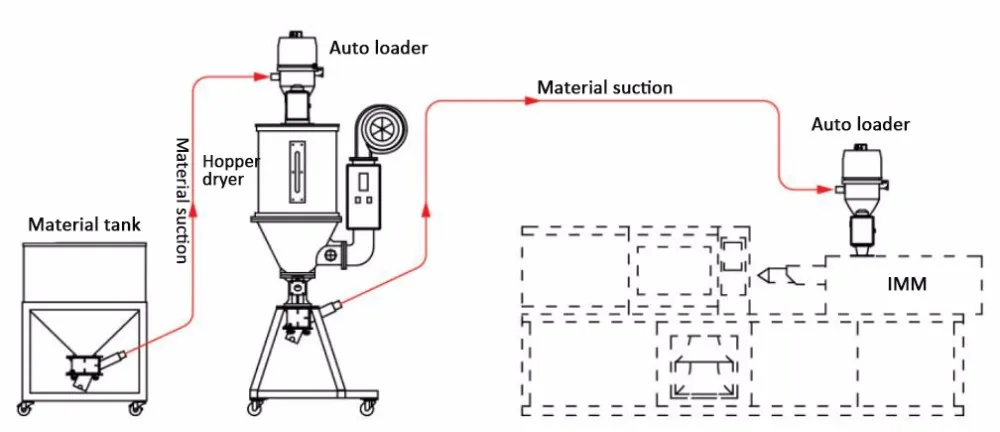

Vacuum Hopper Loader can automatically feeding the material to injection molding machine. When the lack of material in the injection molding machine barrel, it gives signal to the loader to suck material to injection molding machine barrel by ventilation principle. When the material reaches to a certain degree, the loader will stop working until shortage of material again.

Features of Self-contained hopper autoloader

1. Smal footprint & low weight, to be placed directly on other machine for auto loading.

2. Microcomputer controlled.

3. Alarm for overload and lack of material.

4. 300G equipped with high-speed rectifier motor with delicate size and strong suction force, suitable for new material.

5. 400G with vortex high pressure blower, featured with low noise, long service life and energy saving.

6. Cable control board dedign, easy to set and control with distance.

7. Filter for air and dust (Optional part)

Installation diagram

300G

400G

Q1: Are you trading company or manufacturer?

A: We are factory which has over 15 years' manufacturing experience and 80% engineer work have more than 10 years.

Q2: How long is your delivery time?

A: 5 - 20 days after order confirmed. Based on the item and quantity.

Q3: What's the MOQ?

A: 1 set.

Q4: What is your terms of payment?

A: If amount ≤ 1000 USD, 100% in advance, if amount ≥ 1000 USD, T/T 30% as deposit, and 70% balance before shipping. We'll show you the photos of the products and package.

Q5: Where's your general loading port?

A: Shanghai port and Zhangjiagang Port

Q6: Can you do OEM?

A: Yes, we can do OEM.

Q7: Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

Q8: How to deal with the faulty?

A: First, our products are produced in strict quality control system, but if any faulty, we'll send new spare parts for free in one warranty year.

Secondly, our technician will periodically follow up customer to help to do maintenance and ensure equipment operation 7/24 be guaranteed.

Q9: How can get the shipping cost?

A: You tell us your destination port or delivery address, we check with Freight Forwarder for your reference.

-

Xinyi plastic raw material vacuum automatic feeding machine

-

Automatic hopper loader automatic vacuum automatic loader hopper loader

-

Thickened lifting bucket grain elevator hopper lifting bucket HDPE material customization

-

Best Cheap Coffee Bean Feeder and Vacuum Loading Material

-

Plastic Granule Raw Material Vacuum Auto Loader 300G Hopper Loader Industrial Conveyor For Plastic Injection Molding Machine

-

LD Manufacturing Plant T64 Twin Screw Feeder Single Screw Extruder Feeder

-

LD Factory Manufacture Twin Screw Furder Single Screw Extruder Supplier

-

HAL-300G Automatic Hopper Loader Small Vacuum Automatic Loader For CE Compliant Plastic Pellet Injection Molding Machine

-

Hengju Hot Sale 3HP Plastic Material Vacuum Automatic Multi Hopper Loader

-

Fully automatic plastic raw material screw feeder for PVC PP PE granule granule and powder feeder conveying to hopper

Other Products

-

$3040.00 / set

$3040.00 / set -

$13430.00 / set

$13430.00 / set -

$3040.00 / set

$3040.00 / set -

$3040.00 / set

$3040.00 / set -

$662.00 / set

$662.00 / set