Newly designed waste tire recycling machine for rubber powder tire recycling machine production line

-

Supplier: Zhengzhou Yuxi Machinery Equipment Co., Ltd. -

Region: Henan, China -

Contact: Mr John Cai -

Price: $35600.00 /set -

Min. Order: 1 set

| payment terms: | L/C,Western Union,T/T,MoneyGram,Trade Assurance; | Core Components Warranty: | 2 years; |

| Origin: | Henan, China; | Applicable industries: | manufacturing plant; |

| Weight (kg): | 240,000 kg; | Marketing Type: | normal product; |

| type: | tire machine; | Showroom location: | Egypt, Turkey, Brazil, Indonesia, India, Mexico, South Africa; |

| Final product: | rubber particles; | brand: | Yuxi; |

| Mechanical test report: | if; | year: | 2022; |

| port: | any port in China; | Raw materials: | American tire recycling waste rubber tire recycling plant; |

| Dimensions (L*W*H): | 3500*3200*2800mm; | Supply capacity: | 20 waste tire rubber powder machines per month; |

| Main selling point: | automatic; | Power (kW): | 300 kilowatts; |

| Health status: | new; | Video external inspection: | if; |

| Tyre machine type: | tire recycling machine; | Warranty: | 2 years; |

| Voltage: | 220V/380V; | Core components: | engine, bearing; |

| capacity: | 10 tons; | Packaging Details: | 1. The host is packed in bare, container, or according to customer requirements. 2. Small pieces are packed in wooden boxes. High-efficiency semi-automatic waste tire recycling machine waste tire rubber powder machine; |

Rubber powder production line is a new type of innovative equipment.

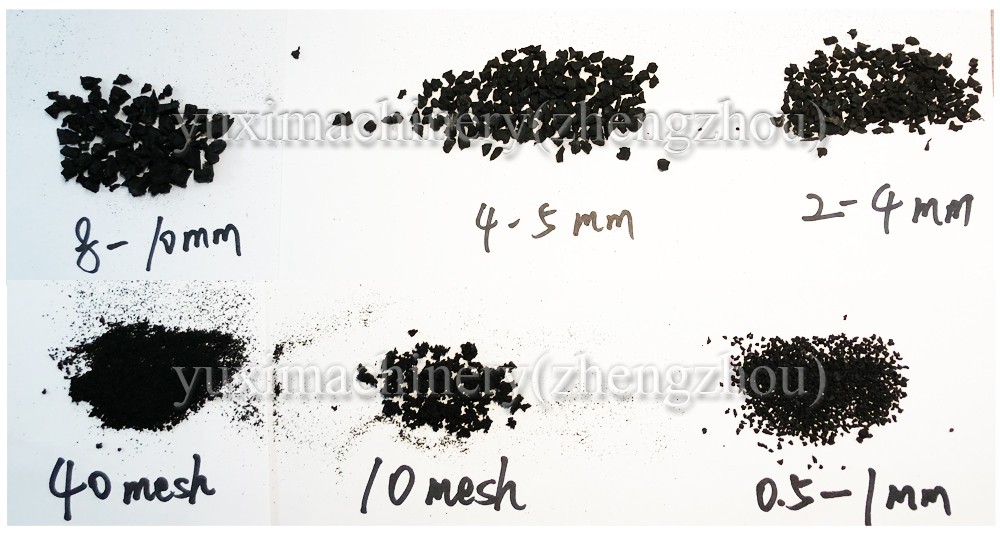

Rubber powder production line for processing waste tires and rubber into fine rubber powder

. The final product size can reach 30-120 mesh, without steel wire and fiber.

capacity | 500-10000kg/h | ||||

Scope of application | Tire diameter: 400-3000mm | ||||

output size | 5-100 mesh, can be customized | ||||

complete separation | Rubber chips, steel and fibers can be automatically separated. Using PLC control system, only 4-6 people can operate a tire recycling (pellet) production line with a capacity of 3000kg/h. Low energy consumption. 3000kg/h tire recycling production (granule) line installed powder is about 800kw. | ||||

Required area of equipment | About 680 square meters, 7m high | ||||

Blade characteristics | long lasting. High utilization rate and multiple maintenance | ||||

Double Shaft Shredder |

Double shaft shredder pretreatment |

The entire tire is approximately50-80mm rubber |

piece. |

motor:As required |

wire separator |

input material≤50mmTire rubber block finished product |

product≤20mm. andwere ableremove 96%of |

tire wire. |

motor:As required |

reducer:As required |

high speed crusher |

Feed≤20mmtire rubber block |

Finished product≤2-6mm. |

motor:As required |

blade:As required |

Product Size:One or more sizes are discharged simultaneously. |

dust |

Dust collection system collects dust and fibers |

crusher by air duct |

Serving. |

Dust removal standard:can be customized |

According to the standards of different countries |

Rubber Grinder |

Rubber grinder is a kind of equipmentSmash 2- |

6mmPure rubber particles into fine powder |

10-140 meshin room temperature. |

motor:As required |

Product Size:One or more sizes are discharged simultaneously. |

What is the final product you want to process?

Application areas:

• Paved sports fields: running tracks, school sports fields, garden paths, bowling alleys, sidewalks, recreation fields, basketball courts, etc.

•Automotive industry: train floors, brake disc ribbons, car and truck floors, shockproof sleeves, weather strips, buffers, shock absorbers, marine daily materials, tires, tire linings, etc.

• Construction and Equipment: Adhesives/Sealants, Hospitals, Corporate Flooring, Insulating Rubber Materials, Carpet Mats, Livestock Straw Mats, Extruded Products, Modular Products, Coatings, Bricks, Sheets, Waterproofing, etc.

1. Packing: 1) Wrap with protective film;

2) Packed in standard import and export wooden boxes or cartons.

2. Transportation: logistics; by car; by train; by transportation; by air, etc.

Q: What kind of tires can be crushed for recycling?

A: Such as cars, trucks, construction vehicles and various tires.

Q: What products do I end up getting?

A: Rubber particles, powders, steel wires and fibers.

Q: What is the capacity range of the waste tire recycling line?

A: We can supply the whole tire powder production line of 500-5000kg/h!

Q: Can you customize the production line according to our budget?

A: Of course. Our factory has a professional team of engineers to design the most suitable solution according to your needs.

Q: Is there a live demonstration of the machine at work available to visit?

A: Of course. Please confirm the exact visit schedule when it is convenient for us to make an appointment with the client, so that the work location can be arranged in advance.

Q: Do you accept L/C payment terms?

A: Of course. We accept letters of credit at sight

Q: What about the delivery time?

A: 60 days after deposit.

Q: Provide installation and technical guidance?

A: 25-30 days for installation work, 2 engineers are trained on site.

-

1-6 axis/shaft type rubber gasket cutting machine for gaskets or rubber rings

-

Rubber pressure bladder for Almex Eupno Beltwin vulcanizing presses

-

Metal Plastic Crusher Biaxial Pet Bottle Grinding Multifunctional Tire Shredder Tire Crusher

-

Factory Direct Sales Truck Radial Tire Retreading Machine/Tyre Retreading Equipment

-

Scrap Tire Sidewall Polishing Machine Circular Cutting Blade

-

Waste Tire Recycling Machine Tire Pulverizer Machine for Rubber Pulverizer

-

Scrap Big Truck Tire Sidewall Cutting Machine Mechanical Recycling Tire Cutting Machine Recycling Machine

-

open mixing mill

-

UT-A2100 Portable Heat Press Machine PVC Conveyor Belt Vulcanizing Machine Air-cooled Crimping Machine

-

Rubber floor tile vulcanizing machine/rubber floor mat making machine

Other Products

-

$29850.00 / set

$29850.00 / set -

$25600.00 / set

$25600.00 / set