FARI GM-5000 Plasma Surface Treatment Machine

-

Supplier: Shenzhen Fangrui Technology Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Tina Jiao -

Price: $3500.00 /set -

Min. Order: 1 set

| Warranty: | 1 year | Core components: | PLC, motor, pressure vessel |

| brand: | Fari | Card: | Fari |

| After Warranty Service: | Online support | place of origin; place of origin: | Guangdong, China |

| Mechanical test report: | if | Core Components Warranty: | 1 year |

| Minimum order quantity: | 1 set | After-sales service provided: | online support, free spare parts, online support |

| Applicable materials: | Plastic, Metal and Glass | Main selling point: | energy saving |

| Showroom location: | South Korea | Local service location: | not any |

| port: | Shenzhen | Health status: | new |

| strength: | 1000W | Marketing Type: | normal product |

| Input voltage: | AC220V 10% 50/60HZ | Supply capacity: | 100 sets per month |

| Applicable industries: | Manufacturing plants, food and beverage plants, household, printing plants | Video external inspection: | if |

| payment terms: | L/C,T/T,Western Union,MoneyGram,Visa | Certificate: | EU standard |

| Name: | Plasma Surface Treatment Machine | Handling width: | 3-18mm |

| application: | Material Surface Activation and Modification |

product name | FARI GM-5000 Plasma Surface Treatment Machine |

brand | Fari |

color | white |

Number of nozzles | 1 |

operating mode | Panel power control, convenient and fast, remote analog control, alarm output control, on-site remote online control. |

Processing width | 3-5mm, 7-13mm, 15-18mm (optional) |

Full set of accessories | Plasma generator, plasma gun |

Certification | ISO9001, CE |

Input voltage | AC220V(±10v) |

Output Power | 1000W |

Dimensions (W*D*H) | 540(W)×210(D)×420(H)mm |

Plasma Power Frequency | 18-25 Hz |

Air supply pressure | 2-3bar |

Gross weight (including packaging) | 18 kg |

Applications

It is used for surface cleaning and activation treatment of printing and packaging, mobile phone and computer digital, silicone rubber, plastic products, metal products, glass precision, wire and cable, electronics, automobiles, medical biology, textile products and composite materials. It plays a key role in the subsequent bonding, printing, coding, spraying, gluing and welding processes.

Plasma surface treatment of cable materials.

Electric kettle with plasma finish.

Plasma surface treatment for cartoner.

feature

The use of chemical products to completely replace traditional material surface treatment, the process does not have any negative impact on the environment.

There are often organics and oxide layers such as grease and oil on the surface of the material, so plasma treatment can bring complete cleaning before sputtering, painting, adhesives, bonding, welding, brazing and PVD, CVD coating. surface, no oxide layer is necessary.

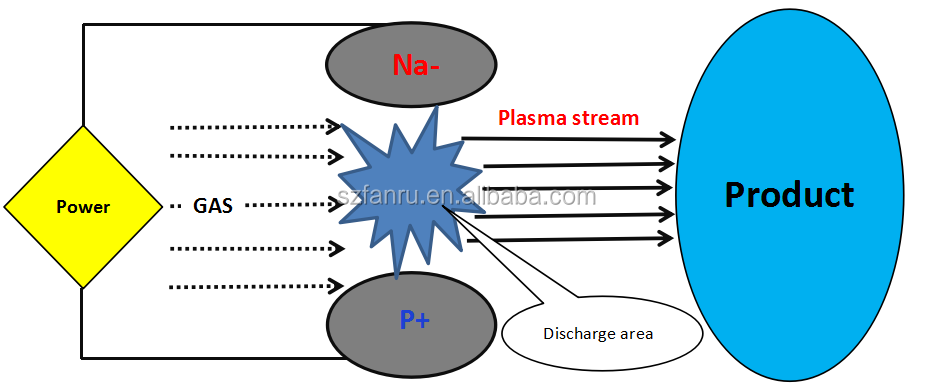

The reaction mechanism is a series of comprehensive physical and chemical reactions. The gas undergoes an ionization reaction under high pressure to generate highly reactive free radicals, which further react with organic pollutants on the surface of the material. The particles bombard the surface of the material to roughen the surface of the material and activate the surface of the material. , greatly increase the hydrophilicity of the material surface, so as to obtain good viscose, printing and spraying effects.

In production and development, we have made a number of technological breakthroughs and obtained a number of invention patents.

Our company has passed ISO9001:2015 quality system certification and CE certification.

Q: Are you a trading company or a manufacturer?

A: We are the manufacturer

Q: How long is your delivery time?

A: If the item is in stock, generally 3-5 days after receiving the order and paying in full. Or 5-7 days if the goods are not in stock, according to the order quantity.

Q: Do you have CE certification?

A: Yes, we have. We can send it to you if you need it.

Q: What are your payment terms?

A: 100% full payment. If you have further questions, please feel free to contact us via email.

Q: Is plasma toxic?

Please don't worry, plasma is non-toxic and will not harm your body

1. One year warranty.

2. During the warranty period, if the parts (except wearing parts) are damaged (non-artificial reasons), we will replace them free of charge (customers should pay the freight).

3. We can provide sample test for free.

4. We support OEM orders.

If you have any questions, please contact us, we will reply you within 24 hours and try our best to solve the problem for you

-

Corona Generator HW-2003G and Corona Station for Blown Film Machine Corona Treater

-

Manufacturer Corona Treater Made in China

-

Thermal splicing press for spindle belt/splicer/flat belt thermal splicer

-

Plastic film corona treatment machine

-

New Product High Efficiency 4 Axis 5 Bulk Diamond Plant Dispensing Machine

-

EVA 3D school bag printing machine

-

Rubber & Plastic Dispersion Kneader

-

High quality Italian socket welding machine for plastic pipes IAM-S./200-630

-

50 tons of FRP light pole hydraulic pultrusion machine

-

Mobile film surface corona treater

Other Products

-

$2150.00 / set

$2150.00 / set