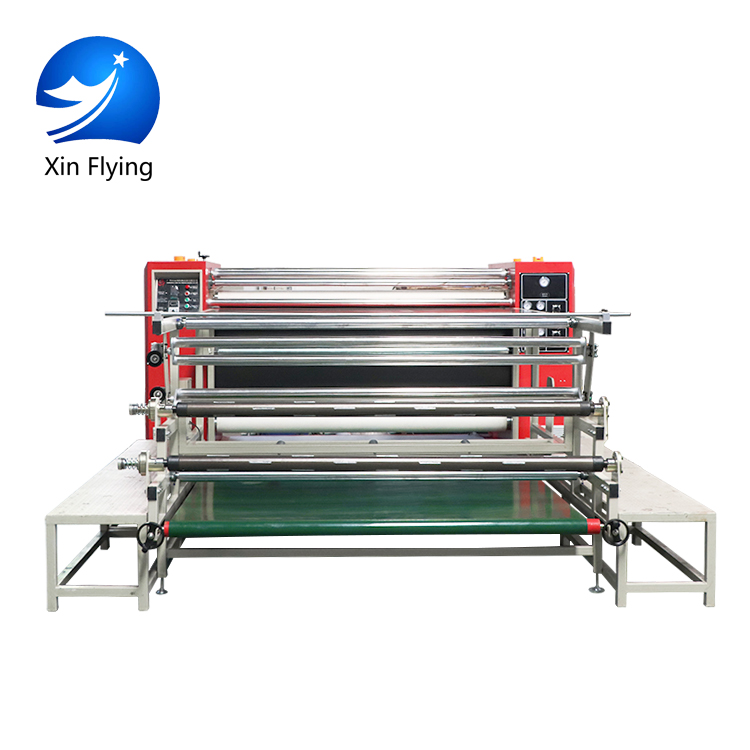

Roller sublimation printing heat press machine for sale roll to roll heat transfer machine

-

Supplier: Guangzhou Xin Flying Digital Technology Co., Ltd. -

Region: Guangdong, China -

Contact: Mr Ken Liu -

Price: $1500.00 /set -

Min. Order: 1 set

| brand: | ink method | type: | spread heat |

| After Warranty Service: | Video technical support, online support, spare parts, on-site maintenance and repair services | Oil drum: | 600mm |

| Minimum order quantity: | 1 set | Type of machine: | multifunctional heat transfer |

| strength: | 34kW | Core Components Warranty: | 3 years |

| port: | Guangzhou/Shenzhen Port | Local service location: | United States, Italy, Vietnam, Philippines, Peru, Pakistan, Mexico |

| application: | fabric heat press | printing speed: | 1-8 m/min |

| Plate type: | Roller heat transfer machine | Auto grade: | automatic |

| Marketing Type: | New Products 2020 | usage: | fabric printer |

| Core components: | pressure vessel | Warranty: | 1 year |

| place of origin; place of origin: | Guangdong, China | Health status: | new |

| Packaging Details: | PVC inner packaging, iron cage outer packaging Packaging size: 1150*1280*2900mm | Supply capacity: | 200 sets per month |

| Colors and Pages: | Polychromatic | payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram |

| Function: | transfer mode | Video external inspection: | if |

| Showroom location: | Turkey, United States, Italy, France, Vietnam, Philippines, Peru, Saudi Arabia, Mexico, Russia | Dimensions (L*W*H): | 3900mm*2640mm*1260mm |

| Printing area: | 1600 mm / 63 inches | Certification: | Chief Executive |

| heating method: | Oil based heating tube | Mechanical test report: | if |

| Applicable industries: | clothing store | After-sales service provided: | Engineers can go overseas to service machinery, online support, free spare parts, on-site installation, commissioning and training, on-site maintenance and repair services, video technical support |

| Voltage: | Three-phase 220V/380V | Main selling point: | long lasting |

| weight: | 1000kg |

Roller sublimation printing heat press machine for sale roll to roll heat transfer machine

scope:

|

Product number |

InkFa4217 |

InkFa 6017 |

Ink Fa8017 |

|

Specification |

420*1700mm |

600*1700mm |

800*1700mm |

|

Drum diameter |

16.5"/420mm |

23.6"/600mm |

31.5"/800mm |

|

Running power |

28kW |

34kW |

54kW |

|

Package dimensions |

1100*1260*2580mm |

1300*1530*2880mm |

1500*1650*2700mm |

|

gross weight |

1200kg |

2000kg |

2700kg |

|

transfer speed |

1-6m/min |

1-8m/min |

1-10m/min |

|

Transmission width |

63 inches/1600 mm |

||

|

Voltage |

Three-phase 220V/380V |

||

|

transfer speed |

Adjustable speed, 150-280m/h |

||

|

Heating type |

oil heating |

||

|

temperature range |

0-399℃ |

||

|

time limit |

0-999 seconds | ||

| workbench | 3m | ||

|

How to operate |

Three release and two close |

||

|

pressure |

with pressure reinforcement system |

||

|

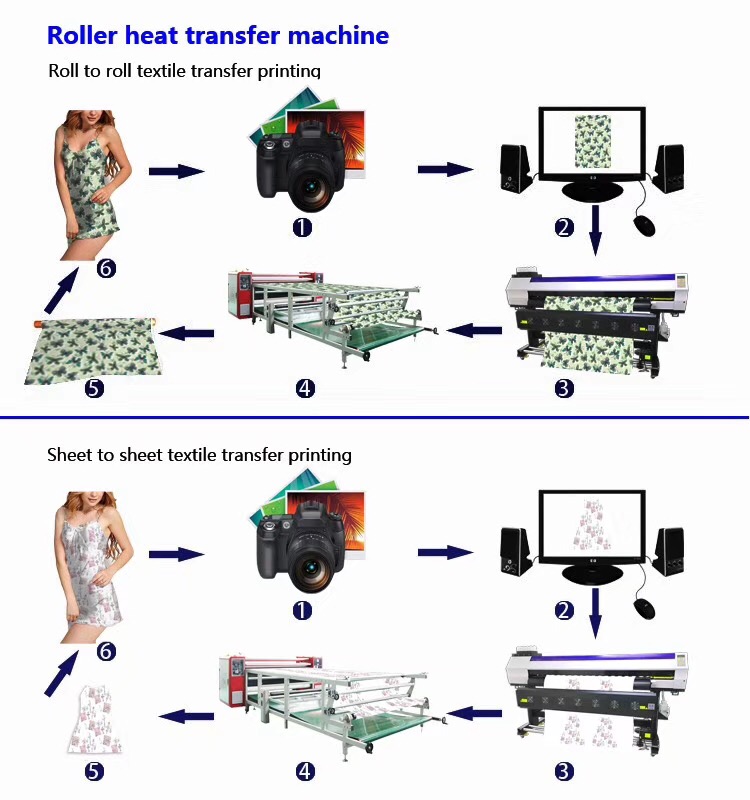

transfer model |

Both for roll-to-roll and sheet textiles |

||

|

Other available widths |

2600mm, 3200mm; Customized size according to your special order |

||

feature:

1. High-end composite steel roller with Teflon coating on the surface, uniform roller temperature and low energy consumption;

2. Equipped with an adjustable air pressure system to adjust the pressure according to different transfer materials, the transfer speed is faster and the color is more beautiful;

3. The self-developed equipment control system adopts high-end electrical components and high-precision parts, and the equipment transmission is more stable;

4. The blanket is automatically separated, and the high-precision silicone pressure balance rod is used to adjust the pressure between the blanket and the roller, effectively reducing the tension of the blanket and prolonging the service life of the blanket;

5. Adopting scientific design, three sets and two sets (three sets: cloth set, transfer paper, protective paper; two sets; cloth collection, protective paper), the equipment operation is more convenient and labor-saving; double-layer oil drum, 100% full heating Oil, surface temperature ±1-2℃;

Roller heat transfer machine details

1. Protect the paper controller that adjusts the delivery speed.

2. Independent switch of external pressure system, pressure control button, easy to operate

3. Emergency stop device. In case of emergency, press the emergency stop device, the machine will stop immediately, with higher safety.

4. The roller pressing device is that the cloth and the blanket are closely attached to the roller, and the blanket is not easy to be deflected.

5. Carbon brush collector ring, 24 hours continuous operation, stable current transmission and high safety

6. Using DuPont full aramid fiber blanket, the blanket is resistant to high temperature, not easily deformed, the surface is smooth, and the fabric transfer has no color difference.

application

It is suitable for sublimation transfer printing in large banners, flags, T-shirts, non-woven fabrics, clothing fabrics, towels, blankets, mouse pads and other products, especially the continuous transfer of fabrics. It can continuously print at a speed to meet the needs of customers for mass printing.

Packaging and Shipping

The machine is packed in PVC, and the machine is packed in an iron cage to prevent collision and damage during transportation. Iron frame packaging is more stable.

-

15 in 1 combination heat press machine sublimation digital display advanced heat transfer machine suitable for T-shirt/mug/hat//slate/glass/dapeng

-

Professional Manufacturer 38 x 38cm Heat Press Machine US Standard 15 x 15 Dye Sublimation Heat Press Machine for T-shirt Pocket Pad

-

Heat Transfer Printing Machine good quality stable heat sublimation printing sublimation calender

-

5 in 1 Heat Press Multifunctional T-shirt Sublimation Printing Machine

-

Ruida Heat Press Machine 8 in 1 Single LCD Display Combined Heat Press Machine 8 in 1 Dye Sublimation Printing

-

BestSub Craft Mug Press Machine 11oz 15oz 20 oz 30oz Plus Sublimation Tumbler Heat Press Mat Cup Press Machine

-

BestSub Custom 11oz 15oz 20 oz 30oz Plus Dye Sublimation Roller Heat Press Cushion Cup Printing Machine

-

Pus For Sale High Pressure Heat Press Large Format 80cm 100cm

-

Guangzhou factory 420mm sublimation roller heat transfer machine for fabric transfer

-

6 station multicolor automatic t-shirt heat press transfer machine pneumatic heat press printing fabric