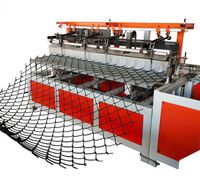

Square mesh weaving machine fiberglass mesh making machine for making wire mesh

-

Supplier: Anping Hongke Wire Mesh Machinery Factory -

Region: Hebei, China -

Contact: Ms Annie Lee -

Price: $3500.00 /set -

Min. Order: 1 set

| color: | client needs | Function: | weave |

| Weight (kg): | 750 | product name: | Fiberglass Net Making Machine |

| place of origin; place of origin: | China | Health status: | new |

| Supply capacity: | 50 sets per month | application: | Fiberglass mesh weaving |

| brand: | Hongke | Voltage: | 380V |

| Type of machine: | Fiberglass Net Making Machine | model: | production line |

| payment terms: | L/C,T/T,Western Union | port: | Tianjin harbor |

| Grid width: | 1000/1300/2000mm | Warranty: | 1 year |

| weight: | 750-1000kg | Packaging Details: | Seaworthy packaging |

| Applicable industries: | manufacturing plant | Power (kW): | 1.5 |

| After-sales service provided: | Engineers can repair machinery overseas | type: | Fully automatic |

| strength: | 1.5KW | Main selling point: | high productivity |

The glass fiber mesh production line consists of warping machine, loom and coating machine.

Specification:

Model | speed | Liang Chang | strength | weight | aspect |

ZJ-400 | 60-90RPM | 1370mm | 3kW | 750kg | 1700x2500x1100mm |

ZJ-800 | 60—90 rpm | 2920mm | 4kW | 1000kg | 1900x4500x1100mm |

warping machine

The warping machine consists of a yarn rack and a main unit that sorts the yarn onto the beam for weaving. The equipment is controlled by two stages of transmission and tension. The speed is turned off and the speed is controlled by the constant speed. Two rollers are used to compress the shaft surface synchronously, so that the disc surface is smoother and more compact, the single yarn tension is more uniform, and there is no yarn breakage and looseness during weaving.Infrared control, it will stop automatically when the yarn is broken.

Specification:

Model | speed | capacity | Product width | grid size | strength | aspect |

ZWJ-1000 | 150-180 rpm | 30-80 meters2/H | 1000mm | 3*3—10*10 | 0.8kw | 1600x2500x1500mm |

ZWJ-1300 | 150-180 rpm | 30-75 meters2/H | 1300mm | 3*3—10*10 | 0.8kw | 1600x2800x1500mm |

ZWJ-2550 | 100-130 rpm | 60-140 meters2/H | 200mm | 3*3—10*10 | 1.5kW | 1800x4200x1600 meters |

Fiberglass Net LoomIt is a kind of equipment for processing glass fiber materials, woven nets, glass fiber safety nets, wall nets, and glass fiber nets for backing. This machine can produce 1m, 1.2m, 1.5m, 2.0m, 2.3m, 2.4m width specifications; the grid density is adjustable between 4 and 12.

Specification:

Model | heating method | Capacity (m2/H) | Preheat time(minute) | grid width | Power (kW) | Dimensions (mm) |

TJL-D1000 | electrical | 600-900 | 15 | 1000mm | 48 | 6000x2000x3800 |

TJL-S1000 | electrical | 1600—2500 | 20 | 1000mm | 95 | 12000x2000x11000 |

TJL-SQ1000 | gas | 1600—2500 | 30 | 1000mm | 8 | 12000x2000x11000 |

ThisCoaterOur company produces two kinds of oil heating and electric heating, which can be customized according to customer needs. The machine includes: coating part, drying part and coiling part.

This machine is suitable for processing grinding wheel nets and glass fiber nets with a width of less than 2m. . The glue is evenly applied, the amount of glue applied is suitable, there is no displacement, and the winding is very smooth.

-

APACHE 0.5-2.5 1.5~5 2-6 6-12mm Fully automatic embossing vibrating screen mesh making machine equipment

-

Automatic High Speed Hot Sale Accordion Razor Barbed Wire Fencing Machine / Razor Blade Making Machine Factory Price

-

HBFL Chain Link Fence Making Machine Price/Wire Mesh Making Machine

-

For sale machinery for making fences with steel wire chains made in China

-

Flat Knitting Metal Wire Mesh Metal Tube Cord Circular Knitting Wire Mesh Machine

-

Manual machines for the production of mesh fences rabitsi Manual machines for the production of chain link fences

-

Automatic welding wire mesh machine factory price

-

Automatic Diamond Wire Mesh Chain Link Fence Mesh Making Machine Equipment Manufacturing Price

-

0.4mm-12mm Crimped Mesh Making Machine Wholesale and Manufacturer

-

chain link fence machine High speed full automatic galvanized diamond mesh