Fully automatic pu sole making machine footwear pouring production line pu sports shoes and safety shoes molding machine

-

Supplier: Foshan Luzhou Pu Machinery Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Sarah Chen -

Price: $40000.00 /set -

Min. Order: 1 set

| Raw materials: | Polyurethane (=ISO+POLY) | Main selling point: | Energy saving, automatic, high precision |

| place of origin; place of origin: | Guangdong, China | Marketing Type: | Hot Products of 2019 |

| payment terms: | L/C,Western Union,T/T | Dimensions (L*W*H): | 8000*9000*2350mm |

| Feature 2: | Automatic mold opening and closing | Video external inspection: | if |

| After-sales service provided: | Engineers can repair machinery overseas | Required labor: | 2~3 people |

| Showroom location: | not any | brand: | Luzhou |

| Supply capacity: | 20 sets per month | Warranty: | 1 year |

| application: | pu soles, insoles, safety shoes, sandals and all other types of pu shoes | strength: | 34KW |

| Production capacity: | 500 to 5000 pairs/day | Packaging Details: | plastic film or discussion |

| weight: | 2800 | Packaging Preview: | |

| Health status: | new | Feature one: | Robotic injection, banana type |

| Mold Station: | 24, 36, 60, 80 or more for choice | Voltage: | 220V/380V |

| port: | Guangzhou, China | Mechanical test report: | if |

| Core components: | PLC, motor, pump | Applicable industries: | manufacturing plant |

| Core Components Warranty: | 1 year |

Fully automatic pu sole making machine footwear pouring production line pu sports shoes and safety shoes molding machine

Applications

The equipment is used to produce polyurethane insoles, outsole, high heels, leather shoes, casual shoes, safety shoes, travel shoes, slippers, sandals, flip-flops and other polyurethane shoes.

Product components

The equipment includes a three-component low-pressure pu foaming machine and a banana-type automatic production line. According to the customer's production capacity, the production line has 24, 36, 60, 80100,

120 or other mold stations are available.

|

Numbering.

|

|||

|

Applicable Foam Type

|

|||

Why choose it:

Why choose it:

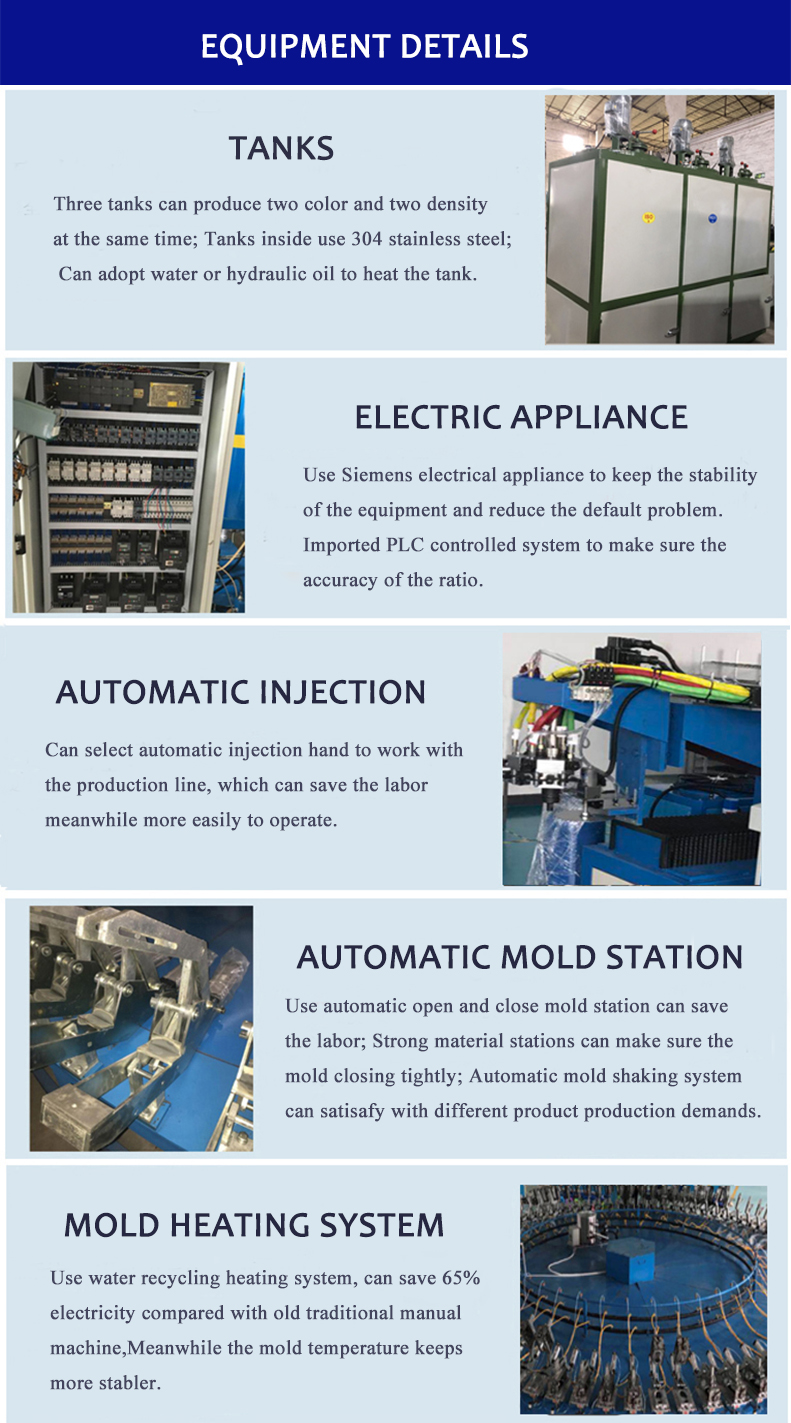

1. Most of the components such as metering pumps and electrical components are imported, which greatly improves the reliability and service life of the equipment;

2.Molds can be opened and closed automaticallyWith a pneumatic system, it canSave labor costs, only about 2 to 4 people are needed for production.

3. Mold circulation heatingwater heating system, it canSave 3/2 electricityIt also makes the temperature of the mold more stable compared to traditional manual machines.

4. The injection can be robot controlled or not, customized for customers.

-

Injection Rubber Slipper Strap Making Machine

-

Sandals Flip Flops Making Machine Making Ladies Slippers For Sale

-

Rotary 20 stations blowing slippers machine women's shoes

-

PVC TPR TPU Monochrome Blow Plastic Shoes High Elasticity Breathable Crystal Slippers Sandals Injection Molding Machine

-

PVC PU Rubber Shoes Sole Vertical Injection Molding Machine for Shoe Making

-

Used refurbished rotary shoe sole injection molding machine with new electronic parts

-

High Quality Customized Fashion Products 1 Color PVC Slippers Sandals Shoes Injection Molding Machine

-

Semi-Auto Monochrome Plastic TPR PVC Sneakers Injection Molding Machine JL-258

-

pvc inflatable shoe machine india

Why choose it:

Why choose it: