Electric Power Steering (EAS) System, EPS 2M CORREIA BELT

-

Supplier: Ningbo Fulong Synchronous Belt Co., Ltd. -

Region: Zhejiang, China -

Contact: Mr LIN JIAN -

Price: $22.16 / 200 - 499 pieces

$18.46 / 500 - 999 pieces

$15.02 / 1000 - 4999 pieces

$8.30 / >=5000 pieces -

Min. Order: 200 pieces

Product details

| Health status: | new | car model: | Land Rover |

| payment terms: | Letter of Credit, Wire Transfer, Paypal | port: | Shanghai/Ningbo |

| type: | Servo 2M | Supply capacity: | 1,000,000 pieces/year |

| Original serial number: | OEM | Packaging Details: | Neutral carton: 400*500*280mm |

| product name: | Electric power steering belt | brand: | CNFULO |

| Certification: | 16949 | Warranty: | 60,000 miles |

| place of origin; place of origin: | Zhejiang, China | size: | 310-2M-17 |

Company Profile

Founded in 1984, Fulong is now a national high-tech enterprise and has passed ISO9001 and TS16949 certification. It has a national laboratory (CNAS) and a municipal innovation center, and has formulated more than ten national and industry standards. And expand 30,000 square meters, and build a number of automatic production lines for automobile synchronous belts and PK belts to ensure OEM quality.

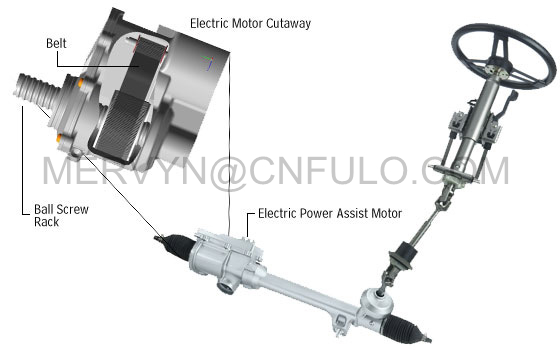

(EPS timing belt, EPS steering system)

Product Description

Hannover, February 2009. BMW, ZF Steering and ContiTech have developed an Electromechanical Power Steering (EPS) with Axial Parallel Layout (APA), which has been successfully used in the BMW 1 and BMW 3 series since 2006 and has therefore been used in the BMW 1 and BMW 3 series. Proven itself in production applications. The system makes an important contribution to environmental protection and optimal driving comfort, as it reduces energy consumption and thus CO2 emissions and requires only minimal steering effort. ContiTech has developed the helical toothed belt CONTI SLT POWER for the timing belt drive of electric power steering.

The electromechanical steering systems of BMW, ZF Steering and ContiTech mainly consist of electric motors, recirculating ball screw spindles and timing belt drives. Compared to the hydraulic version, this type of electromechanical servo system does not require energy in a straight line, thus significantly reducing fuel consumption - up to 0.3 liters per 100 kilometers. It also significantly reduces carbon dioxide emissions. In addition, EPS-APA optimizes driver comfort, as very high forces of up to 13 kN are generated with minimal steering force via the recirculating ball screw spindle on the draw rod. In addition, the steering force can be adjusted to be speed-dependent and progressive by means of suitable software. Another environmentally relevant benefit of EPS-APA is that the system does not require hydraulic oil. Due to the modular structure of the EPS system, it can be easily used in different types of vehicles.

High demands are placed on the timing belt drive of the EPS steering system. Compared to belts operating in an engine environment, belts in steering gear must be able to withstand very low temperatures just above the road surface. It is for this reason that ContiTech Power Transmission has developed the CONTI SLT POWER timing belt. SLT stands for "Extra Low Temperature" as the belt is designed for a temperature range of -40°C to +120°C. “In testing, even peak readings at -45°C and +130°C. This advancement was achieved by using a special EPDM low temperature elastomer that is highly resistant to ageing, cold and Heat resistance," explains Hermann Schulte, R&D Manager at ContiTech Power Transmission Group. Integral fiberglass cords also provide belts with exceptionally high fatigue strength, water resistance and dimensional stability under reverse bending stress.

The comfort benefits of particularly low noise levels also played an important role in the development of BMW, ZF Steering and ContiTech. The sprocket and belt profiles have been specially developed for this application and feature a 5-degree helix angle, ensuring trouble-free tooth engagement and optimized acoustics. To ensure that no belts generate noise levels higher than 45 decibels, each belt is acoustically tested before delivery. "It's a book that's commonly found in ordinary libraries," Schulte compares. During production, each belt has an individual identification mark to ensure the uninterrupted product traceability required by the steering system. The timing belt drive offers a high degree of overload protection: under extreme loads, the belt can jump without damage. The high quality of the product enables the maintenance-free life of the entire steering system to exceed 15 years.

High demands are placed on the timing belt drive of the EPS steering system. Compared to belts operating in an engine environment, belts in steering gear must be able to withstand very low temperatures just above the road surface. It is for this reason that ContiTech Power Transmission has developed the CONTI SLT POWER timing belt. SLT stands for "Extra Low Temperature" as the belt is designed for a temperature range of -40°C to +120°C. “In testing, even peak readings at -45°C and +130°C. This advancement was achieved by using a special EPDM low temperature elastomer that is highly resistant to ageing, cold and Heat resistance," explains Hermann Schulte, R&D Manager at ContiTech Power Transmission Group. Integral fiberglass cords also provide belts with exceptionally high fatigue strength, water resistance and dimensional stability under reverse bending stress.

The comfort benefits of particularly low noise levels also played an important role in the development of BMW, ZF Steering and ContiTech. The sprocket and belt profiles have been specially developed for this application and feature a 5-degree helix angle, ensuring trouble-free tooth engagement and optimized acoustics. To ensure that no belts generate noise levels higher than 45 decibels, each belt is acoustically tested before delivery. "It's a book that's commonly found in ordinary libraries," Schulte compares. During production, each belt has an individual identification mark to ensure the uninterrupted product traceability required by the steering system. The timing belt drive offers a high degree of overload protection: under extreme loads, the belt can jump without damage. The high quality of the product enables the maintenance-free life of the entire steering system to exceed 15 years.

ContiTech has developed the helical toothed belt, CONTI SLT POWER, for the timing belt drive of BMW, ZF steering systems and ContiTech's electromechanical steering systems.

ContiTech, based in Hannover, is a world number one. 1 rubber and plastics technologist in the non-tire rubber field. The company develops and manufactures functional components, assemblies and systems for

employee. In 2008, it achieved sales of around 3 billion euros.

ContiTech is a division of Continental AG. With sales of more than 24 billion euros in 2008, Continental is one of the world's top automotive suppliers. As a supplier of braking systems, systems and components for powertrain and chassis, instrumentation, infotainment solutions, vehicle electronics, tires and technical elastomers, the company contributes to improving driving safety and protecting the global climate. Continental is also a strong partner in the field of connected car communications. Today, the company employs nearly 140,000 people at approximately 190 locations in 35 countries.

factory

National Laboratory

Packaging and Shipping

touch

Export Department

Sales Manager

Mr. Zhou Merwen

Email: MERVYN(AT)CNFULO.COM

Website: http://www.cnfulo.com

Tel: 0086 (0)574-6378-7729

Fax: 0086 (0)574-6378-0109

Tel: 0086 13566062254 (WhatsApp/WeChat)

Address: No. 300 Cilong West Road, Longshan Town, Cixi City, Ningbo City, Zhejiang Province, China

VIEW MORE

You may like

-

ND RHD reveal steering gear box oem QAF500110 QAF500120 QAF000040 for land rover

-

For FORD EXPLORER 2013-2015 Steering System Parts Hihg Factory Quality Power Rack EB5Z3504A DB5Z3504C

-

ZUA factory direct sales of high-quality automotive power steering system accessories gearbox steering rack and pinion Japanese car best price

-

Suitable for Audi A4 A5 A6 A7 A8 Q5 Q7 rack and pinion steering box bearing

-

AE5Z-3504-BE Fusion AE5Z3504BE AE5Z3504DE AE5Z3504EE Power steering rack

-

ALNSU Wholesale Auto Steering Systems Mechanical Steering Gear Rack For Corolla NZE170 ZRE171 ZRE173 45510-02600

-

Corolla steering gearbox NZE170 ZRE171 ZRE173 45510-02600

-

Ford Ranger EVEREST BT50 15-18 EB3C3D070BF 38014333013 38014333011 LHD Electric Power Steering Rack and Pinion

-

Hot Sale Electric steering gear EB5Z3504A for FORD EXPLORER 2013-2015

-

3GD827469A 3GD 827 469A 3GD-827-469A auto parts rear view camera for volkswagen passat golf tiguan cc

Other Products

-

$8.30 - $22.16 / piece

$8.30 - $22.16 / piece