Three-in-one busbar processing machine DHY-200 hydraulic copper busbar bending and punching machine

-

Supplier: JUGAO CNC MACHINE JIANGSU CO LTD -

Region: Jiangsu, China -

Contact: Mr Gary Gao -

Price: $1380.00 /set -

Min. Order: 1 set

| Input voltage/Control voltage: | Single-phase 50Hz, 220V | Main selling point: | multifunctional |

| Video external inspection: | if | Cutting range: | 200mm(width)X12mm(thickness) |

| Showroom location: | not any | Name: | CNC hydraulic busbar processing machine |

| Applicable industries: | Building material stores, machinery repair shops, manufacturing plants, retail, construction works, advertising agencies | Core components: | motor |

| Bending range: | 200mm(width)X12mm(thickness) | maximum. Thickness (mm): | 12 mm |

| Single package size: | 80X75X110 cm | The distance from the hole to the edge of the board: | 110mm |

| Punching range: | customizable | Rated working oil pressure: | 700 kg/cm² |

| Sales unit: | single product | Function: | cutting, punching and bending, cutting, bending, punching |

| Core Components Warranty: | 1 year | Packaging Details: | Three-in-one busbar processing machine DHY-200 Hydraulic copper busbar bending and punching machine, wrapped with plastic film and fixed in the container with steel wire |

| Processing material: | Copper Busbar/Aluminum Busbar | Marketing Type: | normal product |

| place of origin; place of origin: | Jiangsu, China | maximum. Width (mm): | 200 mm |

| Weight (kg): | 200 | Type of machine: | Busbar processing machine |

| Health status: | new | Warranty: | 1 year |

| Mechanical test report: | if | CNC or not: | normal |

| Gross weight per piece: | 200.000 kg |

Buyers can purchase machines directly by paying online.

Note: The price only includes sea freight from Shanghai port to buyer's local port. Does not include local customs clearance fees!

Three-in-one busbar processing machine DHY-200 hydraulic copper busbar bending and punching machine

feature

1. This machine provides the guarantee and supporting design of efficiency and safety requirements.

2. The machine is equipped with: bending, cutting and punching functions.

3. There is no burr for punching, the cutting surface is smooth, and the cutting angle is accurate. It works for puick and repeat batches.

4. High flexibility, small size, high power, high productivity and high work efficiency.

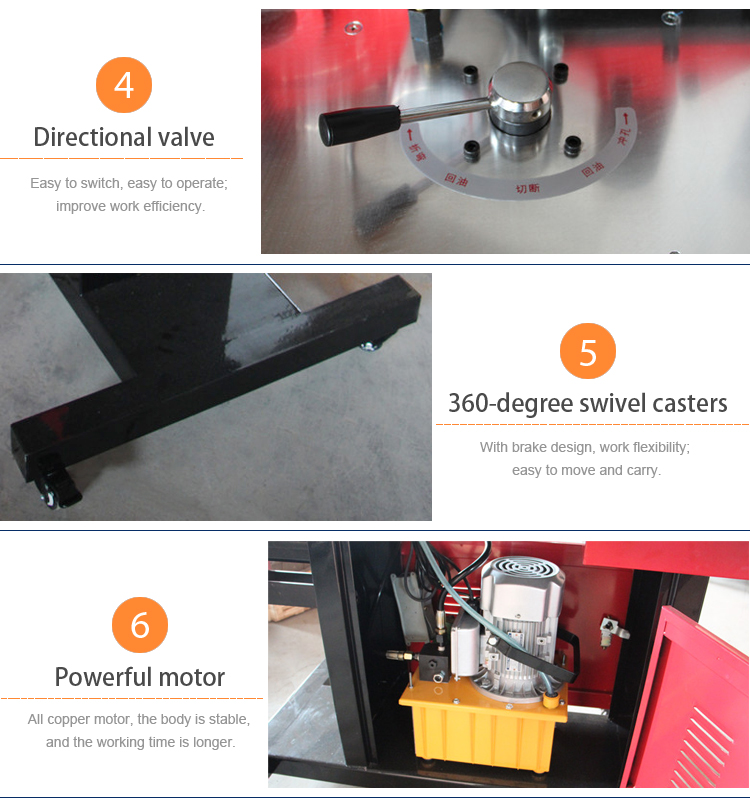

5. Safe and firm foot switch controls oil intake and oil return. Low noise, harmless disposal.

6. The finished product is beautiful and will not pollute the environment.

application

This processor is suitable for making large electrical cabinets, power distribution cabinets, switch cabinets and construction sites for power transmission and distribution construction projects. Suitable for large workshops and on-site construction, power transmission and distribution and distribution cabinets and switch cabinets, etc.

technical parameter

| Model | DHY-200 |

| Function | Three functions, cutting, punching and bending |

| with electro-hydraulic pump | Foot valve control with solenoid valve |

| Processing material | Copper Busbar/Aluminum Busbar |

| Processing range | 200mm wide, 3-12mm thick |

| desk size | 800mmX750mmX1100mm |

| Input voltage | Single-phase 50Hz, 220V (we can meet your needs) |

| Rated oil pressure | 700 kg/cm2 |

| cutting force | 30T |

| Cutting range | 200mm(width)X12mm(thickness) |

| bending force | 35T |

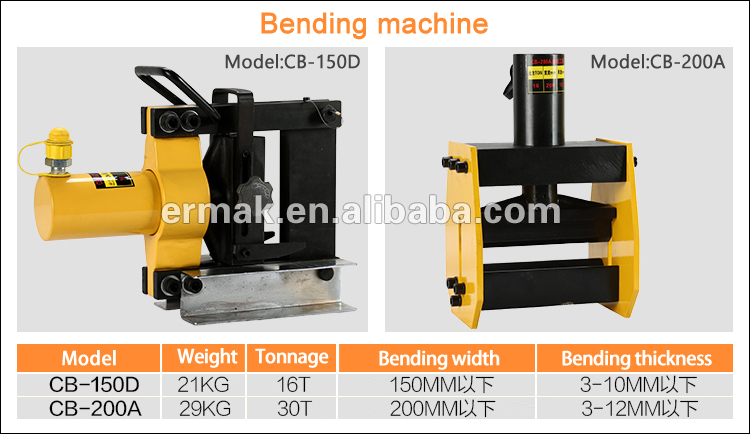

| Bending range | 150mm(width)X10mm(thickness) |

| Bending angle | 0-90° |

| punching force | 31T |

| Punching range | Shock (Φ7, 9, Φ10.5, Φ13.8, Φ17, Φ20.5, Φ22) can be customized |

| The distance from the hole to the edge of the plate | 110mm |

| weight | 200kg |

feature:

CH-60.CH-70 split hydraulic punching machine is specially used for punching metal plates such as angle iron, flat iron and copper plate. It is especially suitable for operations in electric power, construction and other industries.

feature:

CWC-150.CWC-200 is a tool for cutting copper and aluminum busbars. The knives are made of alloy steel and heat treated. The fracture is smooth and tidy, flat and not deformed, and there is no waste on one side. CWC-200V copper bar is cut into arc copper chips.

feature:

CB-150D hydraulic bending machine is suitable for bending metal materials such as copper, aluminum and iron plates. It has a curved angle style. The bent bus bar will not be twisted, and the workpiece can be easily taken out after bending. The product is sturdy. When bending long copper strips, N-type or L-type can be used to take out the card, so that the whole row can be taken out without hindrance. The busbar can be bent 0-135° in its vertical plane.

Please click here>>>>Contact us for more ex-factory prices, shipping and discounts.

|

|

warranty period:

Our product quality guarantee period is 12 months from the date of bill of lading. During the warranty period, if the quality is unqualified due to our reasons, we will provide spare parts for free. If the failure is caused by improper operation of the customer, we will provide the customer with spare parts at the cost price. We can also provide flexible extended warranties based on actual conditions.

After-sale service:

Under the condition that you provide round-trip air tickets, visa procedures, accommodation and other conditions, our engineers can come to your factory to install and show the operation details. In turn, your engineers can come to our factory to learn installation, operation and maintenance for free.

Why choose us:

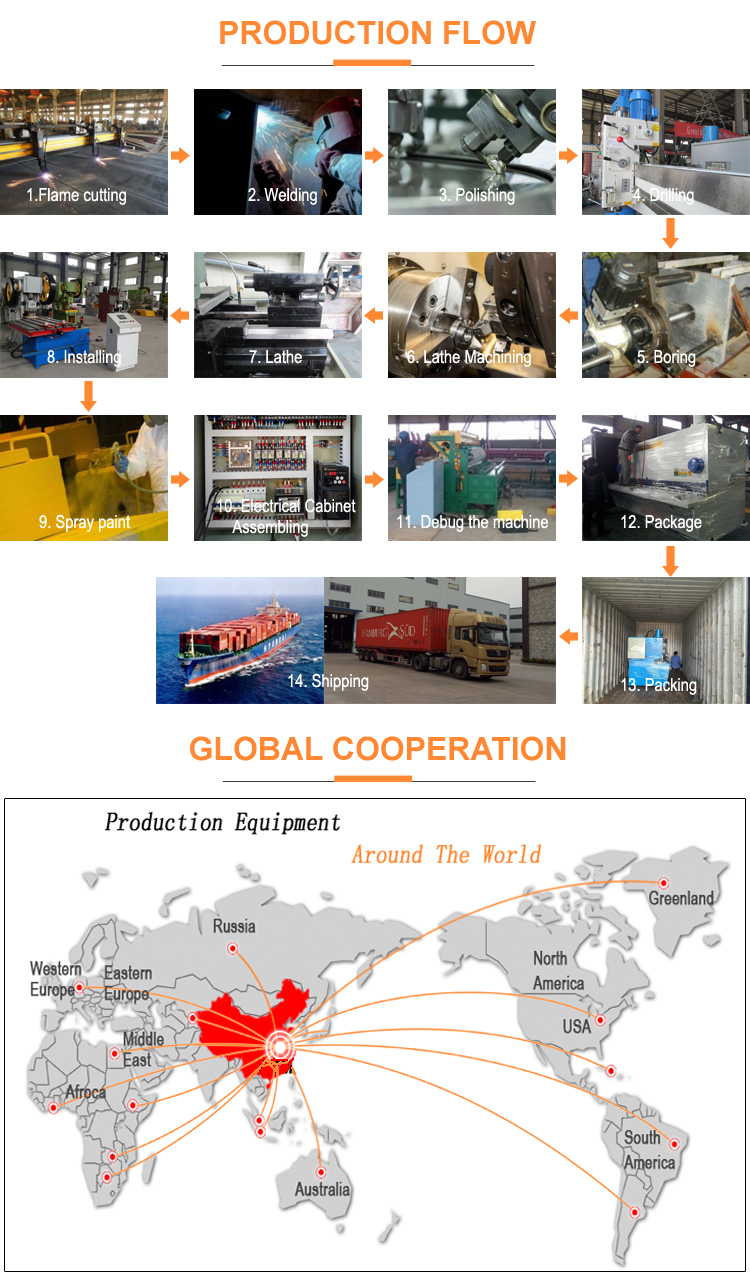

1. We run the machine for a few days and test it with your material. We will only ship if the machine is guaranteed to perform at its best.

2. Our elite team can provide you with professional, customized and all-round services around the clock. If you need any assistance, please contact us via WHATSAPP, Skype, Email or Phone.

How we can provide you with efficient service (metal processing solutions):

Divided into the following three steps:

1. Collect your requirements according to your actual work situation.

2. Analyze your information and provide us with feedback.

3. Provide options based on your specific needs. For example, register. For standard products, we can provide professional advice; for registered non-standard products, we can provide professional design.

|

|

-

Thickness 10mm busbar hydraulic pipe bender CB-150D copper busbar pipe bender

-

DHY-150 Punching, cutting and bending three-in-one multifunctional busbar machine

-

Three-in-one busbar processing machine VHB-200 hydraulic copper busbar bending cutting punching machine

-

Busbar punching bending cutting machine HB-150W three-in-one hydraulic automatic busbar processing machine

-

DHY-200 max 200 x 12mm 3 in 1 hole punching bending machine Copper hydraulic busbar processing machine

-

DHY-200 Three-in-one Hydraulic Busbar Cutting and Bending Machine

-

copper busbar bending machine hydraulic busbar bending machine busbar bending machine drilling cutting machine

-

Hydraulic Punching Copper Busbar Bending Machine Desan Busbar Machine

-

Multifunctional busbar processing machine Copper and aluminum cutting bending punching three-in-one busbar processing machine

-

Copper Aluminum Bending Busbar Processing Machine