High quality organic npk compound fertilizer making machine drum granulator for sale

-

Supplier: Qingdao Oriental Agri-Tech Co., Ltd. -

Region: Shandong, China -

Price: $1000.00 /set -

Min. Order: 1 set

| application: | Granular fertilizer making machine | brand: | East |

| Dimensions (L*W*H): | custom made | port: | Qingdao, China |

| Packaging Details: | Small products or parts by sea are mostly packed in nylon bags, wooden boxes and tin boxes. The key parts of large equipment are independently protected. Most of the exposed or plastic film shielded customers with special packaging requirements need to communicate with our factory in advance | payment terms: | letter of credit, wire transfer |

| color: | customer request | After-sales service provided: | On-site installation and commissioning training, on-site maintenance and repair services |

| Type of machine: | Granulator | place of origin; place of origin: | Shandong China |

| Product Category: | fertilizer | usage: | Production of NPK Compound Fertilizer Granules |

| Health status: | new | capacity: | 10000-300000T/Y |

| Voltage: | custom made | Material: | Carbon steel |

| Raw materials: | Organic/Inorganic Materials | product name: | Dry Granulator |

| type: | Rotary Granulator | Warranty: | 1 year, 1 year |

| Certification: | ISO9001 | Name: | Organic Fertilizer Granulator |

| strength: | custom made | weight: | 1-10 tons |

| Supply capacity: | 300,000 tons/year |

Drum granulator

Rotary drum granulator is one of the key equipments in the fertilizer industry, suitable for high, medium and low content cooling, heating, spraying, ammoniated granulation and large-scale fertilizer production.

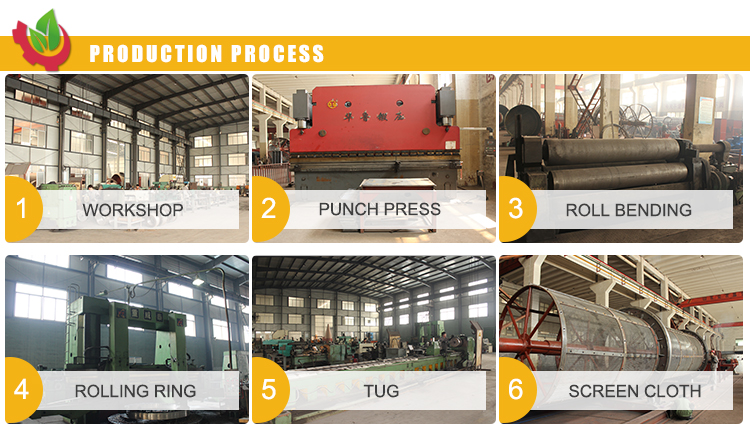

The cylinder body adopts special stainless steel and rubber sheet lining structure. It automatically removes scars and removes burrs. It has the advantages of high particle strength, high output, anti-crossing, wear resistance, low energy consumption, long service life, convenient operation and maintenance, etc.

Remarks: Production speed, granulation rate and particle diameter are affected by different formulations, processes and raw materials.

Drum granulator features

1) It is used for the production of high, medium and low concentration compound fertilizers, with a wide range of applications and low investment costs.

2) The shell of the granulator is lined with special rubber, which is corrosion-resistant and has a long service life.

3) High ball strength, good appearance quality, convenient operation and maintenance.

| Model | shell diameter (mm) | capacity (tons/hour) | inclination of the shell (degree) | Rotating speed (rev/min) | Motor Power (kilowatt) |

| ORT-01A | Φ1400 | 3-4 | 2-2.5 | 13.5 | 11 |

| ORT-02A | Φ1600 | 5-8 | 2-2.5 | 12 | 15 |

| ORT-03A | Φ1800 | 8-10 | 2-2.5 | 11.5 | 18.5 |

| ORT-04A | Φ2000 | 10-15 | 2-2.5 | 10.2 | twenty two |

| ORT-05A | Φ2200 | 16-20 | 2-2.5 | 9.7 | 30 |

| ORT-06A | Φ2400 | 20-22 | 2-2.5 | 9.7 | 45 |

| ORT-07A | Φ2600 | 22-30 | 2-2.5 | 9.2 | 55 |

-

Chicken manure granulator fertilizer/twin roll extrusion granulator fertilizer for sale

-

Industrial large capacity ZL rotary dry granulator granulator mixing granulator food powder processing production line

-

Ganulator Machine Chemicals, Minerals, Inorganic Powder Granulator Fertilizer Double Roll Press Machine Customized 15kw, 30kw CN; JIA 1t

-

Cat litter bentonite granulator/dry powder granulator

-

Organic fertilizer granulator

-

Latest Design Urea Fertilizer Production Equipment

-

1000-1800 kg organic fertilizer bentonite pellet machine per hour

-

Fully automatic urea fertilizer plant/NPK fertilizer production line fertilizer machine

-

Disc Granulator Fertilizer Disc Granulator

-

npk fertilizer manufacturing machinery factory

Other Products

-

$450.00 / set

$450.00 / set