Crude oil refinery peanut oil degumming, dephosphorization, decolorization

-

Supplier: Jingdezhen Huiju Technologies Co., Ltd. -

Region: Jiangxi, China -

Contact: Mr Bill Zou -

Price: $1750.00 / 1 - 2 pieces

$1650.00 / >=3 pieces -

Min. Order: 1 piece

| After-sales service provided: | Free spare parts, video technical support, online support | place of origin; place of origin: | Jiangxi, China |

| Voltage: | 220v, 380v | After Warranty Service: | Video technical support, online support, spare parts |

| Core components: | spare parts | Main selling point: | automatic |

| application: | Fresh Nut Seed Refinery | Production capacity: | 98%-100% |

| Applicable industries: | Restaurant, household, edible oil refiner | Health status: | new |

| Maximum capacity: | 500 kg/h | port: | Qingdao, Ningbo, Shanghai, Shenzhen |

| Local service location: | not any | type: | oil refiner |

| Packaging Details: | wooden box | Auto grade: | automatic |

| Video external inspection: | if | weight: | 140kg |

| Certification: | Chief Executive | Core Components Warranty: | 1 year |

| Supply capacity: | 100 pieces per day | payment terms: | L/C,Western Union,T/T,MoneyGram,alibaba trade insurance, Paypal |

| brand: | Huiju | Oils: | Linseed Oil, Soybean Oil, Rap Seed Oil, Tea Seed Oil, Basil Oil, Sesame Oil, Pine Nut Oil, Sunflower Oil, Almond Oil, Walnut Oil, Peanut Oil, Coconut Oil, Olive Oil, Palm Oil |

| Dimensions (L*W*H): | 165*85*140cm | Marketing Type: | Popular products |

| Mechanical test report: | if | Warranty: | 1 year |

| usage: | edible oil | life: | 15-20 years |

| Showroom location: | not any |

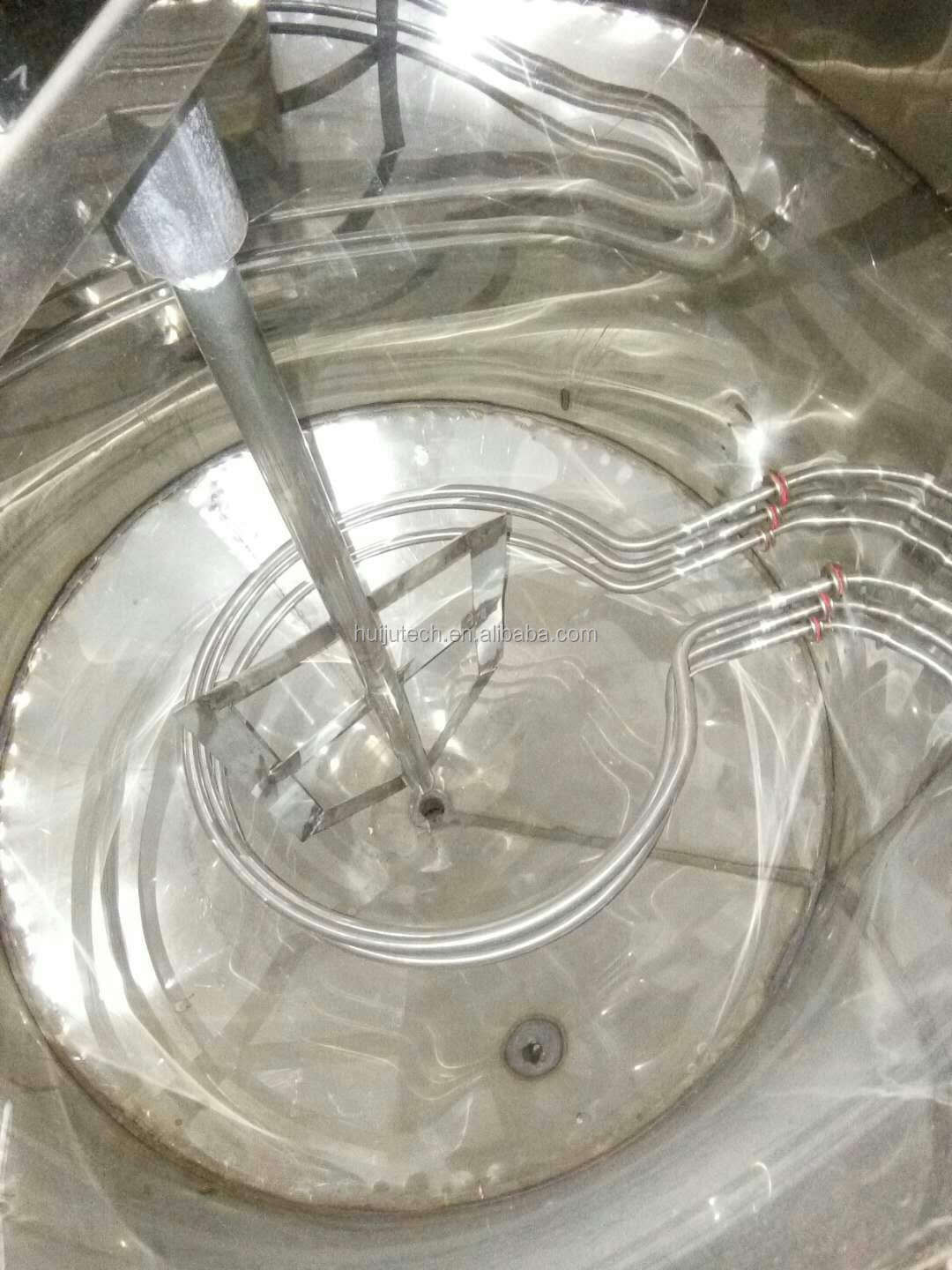

Crude oil refinery peanut oil degumming, dephosphorization, decolorization

|

Model: HJ-JLYJ200 Refiner Machine size: 165*85*140cm Gross weight: 140kg Function: degumming, dephosphorization, decolorization With filter system, a barrel of 75 kg is about 500 kg in 24 hours Voltage: heating power 4kw/220v/380v |

Common parameters of oil products

Composition of Crude Oil

|

Oil name |

Soap content (106) |

Phospholipid content |

Solid impurity content |

|

Rapeseed / Rapeseed |

2300 |

0.63 |

2%-6% |

|

peanut |

1100 |

0.84 |

1%-4% |

|

soybean |

2700 |

1.10 |

3%-7% |

|

sunflower seeds |

2200 |

0.57 |

2%-8% |

|

cotton seeds |

5000 |

0.70 |

3%-8% |

Composition of Refined Oils

|

Oil name |

Soap content (106) |

Phospholipid content |

Solid impurity content |

|

Rapeseed / Rapeseed |

30 |

0.005 |

≤0.05% |

|

peanut |

20 |

0.006 |

≤0.01% |

|

soybean |

60 |

0.006 |

≤0.03% |

|

sunflower seeds |

80 |

0.15 |

≤0.04% |

|

cotton seeds |

110 |

0.012 |

≤0.05% |

Function

HJ-JLYJ200 operation process

1. Pour the filtered oil into the first mixing tank (note: the height of the oil must exceed the heating tube)

2. Turn on the stirring switch, and the speed is 45-55 RPM (revolutions per minute) (Note: There is a knob on the side of the electric box to adjust the speed).

3. Turn on the heating switch and set the temperature of the thermostat to 62 degrees.

4. When the temperature reaches 62 degrees, slowly pour the prepared citric acid solution into the stirring tank (the ratio of citric acid and water is 50kg water to 2.5kg citric acid, and the ratio of oil to citric acid solution is 50kg oil and 0.5-1.5kg citric acid solution, the water temperature must be between 80-100 degrees)

5. Turn off the heat and agitation switches after 30 minutes. After 30-60 minutes of natural precipitation, remove the impurities from the glue outlet until clean oil is discharged from the glue outlet, and then close the glue outlet.

6. Turn on the stirring and heating switches and set the temperature to 110 degrees. 30-60 minutes after the temperature reaches 110 degrees, take a small sample and put it into the pot to test to confirm whether there is water in the oil. (Note: How to test the water content: Pour the finished oil into the pot, then heat the pot. If there is no water in the oil, you cannot hear the sound of water.)

If there is still water, continue heating until the sample is free of water. Then turn off the agitation and heat switches.

7. When the oil temperature naturally drops to about 80 degrees, set the oil pump switch to filter the oil into the oil filter tank. (Note: A portion of the mixed oil will come out when the filtration starts. Note that there is a 3-way valve under the box. When the wrench is at a ninety-degree angle to the tube, the oil will flow back. To the first mixing tank. Until the mixed oil is clear , align the wrench and the pipe, the oil goes into the finished tank).

If the oil needs to be decolorized, add 10 cm thick clay to the filter tank, which needs to be replaced every day in summer.

-

Mustard, soybean, sunflower seed oil press, 200-300kg/h, mustard oil press / circulating oil press

-

Volkswagen Sunflower Peanut Soybean Machine Oil Filter / Centrifuge Oil Filter Oil

-

Hot Sale Cold Mini Coconut Oil Press Oil Press Machine

-

Mini Household Oil Press Grain Cold Press Oil Press

-

Factory direct supply small oil press hydraulic press filter press wholesale price pp

-

20 tons automatic palm oil mill making machine palm fruit oil mill in malaysia

-

Black Seeds Mustard Seeds Nuts Almond Cashew Nut Oil Press Mill Press Extruder / Peanut Oil Press

-

Automatic Moringa Seed Oil Extractor Mini Oil Press for Sale

-

High efficiency sunflower oil production machine including Extraction / Refining / Filling

-

small edible oil refiner crude oil refiner, small vegetable oil refiner

Other Products

-

$2115.00 - $2350.00 / piece

$2115.00 - $2350.00 / piece -

$1700.00 - $1750.00 / piece

$1700.00 - $1750.00 / piece -

$619.00 / set

$619.00 / set -

$830.00 / set

$830.00 / set -

$229.00 / piece

$229.00 / piece -

$425.00 / set

$425.00 / set -

$1.00 / set

$1.00 / set -

$240.00 / piece

$240.00 / piece -

$1295.00 / set

$1295.00 / set