Low carbon steel straight wire drawing machine for wire binding

-

Supplier: Hebei Sade Machine Manufacturing Co., Ltd. -

Region: Hebei, China -

Contact: Ms Alice Zhang -

Price: $9100.00 /set -

Min. Order: 1 set

| brand: | Sadd | Warranty: | 1 year |

| port: | Tianjin Xingang | payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram |

| Showroom location: | Morocco, South Korea, UAE, Colombia, Algeria | weight: | 2 tons |

| type: | programmable logic controller | Maximum incoming line: | 6.5mm |

| Marketing Type: | New Products 2020 | Inlet diameter: | 6.5mm |

| Outlet diameter: | 2mm | Function: | nail |

| Applicable industries: | Building Materials Store, Energy & Mining | Minimum outlet: | 2 mm |

| Mechanical test report: | if | strength: | 18.5-30 |

| weight: | 2000 | Core Components Warranty: | 2 years |

| Core components: | programmable logic controller | Voltage: | 380V/440V/110V, 50Hz/60Hz |

| Machine name: | Single wire drawing machine | Key words: | Drawing Machine |

| Packaging Details: | Bare metal, accessories or tools packed in carton or wooden case covered by plastic film. | Health status: | new |

| After-sales service provided: | Engineers can repair machinery overseas | place of origin; place of origin: | Hebei china |

| Main selling point: | high productivity | usage: | brushed steel/copper/brass/aluminum/stainless steel wire |

| Supply capacity: | 1 single wire drawing machine per month | Dimensions (L*W*H): | 1.7X0.115X1.75 |

| Block speed: | 245 meters | Video external inspection: | if |

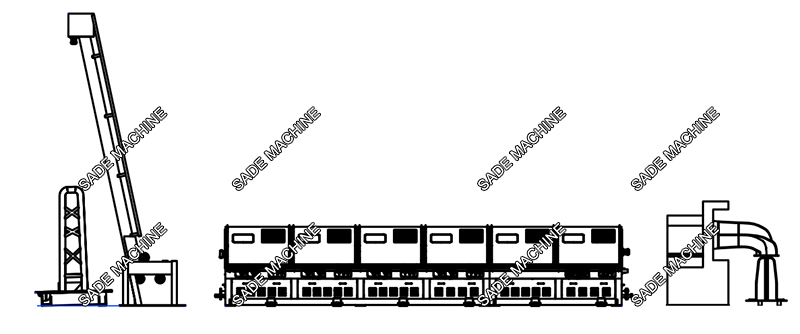

The machine is of high quality off the finished product line, with smooth surface and uniform thickness, using a good cooling system, water cooling and air cooling, with good quality, high reliability and low downtime. This model adopts PLC+ frequency conversion speed regulation, which is easy to operate.

The structure includes hydraulic pay-off, hydraulic descaling machine, brush descaling machine, main block and hydraulic take-up machine. The detail part can be designed and requested according to your detail needs.

technical parameter:

|

Project Design/Type |

LN9-900 |

LN9-800 |

LN9-700 |

LN10-600 |

LN10-400 |

|

Drum diameter/mm |

900 |

800 |

700 |

600 |

400 |

|

Drawing Pass/Time |

9 |

9 |

9 |

10 |

10 |

|

maximum. Incoming wire diameter/mm |

8-14 |

8-10 |

6.5-8 |

5.5-6.5 |

1.8-2.5 |

|

minute. Outlet diameter/mm |

3-5 |

3-4 |

2.5-3 |

1.8-2 |

0.75-1 |

|

Drawing speed/m/min |

300 |

360 |

480 |

750 |

840 |

|

Incoming line strength/kg/mm2 |

≤1300 |

≤1300 |

≤1300 |

≤1300 |

≤1300 |

|

Total compression rate/% |

85.94-87.24 |

84-85.94 |

85.21-85.94 |

89.29-90.53 |

87.24 |

|

Average compression rate/% |

19.58-20.48 |

18.42-19.58 |

19.13-19.58 |

21.00-21.02 |

18.61 |

|

Motor power/kW |

90-110 |

55-90 |

55-75 |

22-37 |

7.5-15 |

The structure includes hydraulic pay-off, hydraulic descaling machine, brush descaling machine, main block and hydraulic take-up machine. The detail part can be designed and requested according to your detail needs.

Recommended machine:

New descaling machine:

Advantage:

1.Water cooling reduces the heat generated during the drawing process, reducing

Die loss, improve wire quality.

2.The finished wire is of high quality, with a smooth surface and uniform thickness.

3. Tungsten carbide sprayingdrum kit, long lasting

4.High speed, variable frequency speed regulation

Pit Annealing Furnace

Annealing furnace is a cycle-operated electric furnace, which is mainly used for heat treatment of metal and alloy parts in equipment.

The resistance furnace is composed of furnace body, furnace lining, heating element, furnace cover mechanism, furnace bottom plate, power distribution cabinet, control system and other accessories.

-

Annealed wire high-speed linear drawing machine, galvanized wire winding machine

-

Monoblock drawing machine for steel bar drawing

-

wet drawing machine

-

Automatic Sheet Metal Polishing Deburring Machine Wide Band Sander For Cutting And Stamping Parts

-

Fire extinguisher barrel deep drawing hydraulic press

-

Cold Rolling Equipment Manufacture 3 Ribbed Steel Bar Machine

-

Small wire drawing machine for making copper wire

-

3 drum wire drawing machine / wire drawing machine

-

0.7mm-0.13mm kitchen Baibao wire drawing machine, stainless steel wire drawing machine

-

Nail horizontal single block wire drawing machine