Stepping lap core cutting machine transformer core wire

-

Supplier: Wuxi Haoshuo Technology Co., Ltd. -

Region: Jiangsu, China -

Contact: Mr Rene Chen -

Price: $100000.00 /set -

Min. Order: 1 set

| Video external inspection: | if | Name: | Stepping lap core cutting machine transformer core wire |

| color: | green | Slitting speed (m/min): | 80 - 120 m/min |

| Main selling point: | automatic | Maximum slitting bar: | 12 |

| Slitting width (mm): | 40 - 1200 mm | Marketing Type: | Hot Products 2022 |

| type: | Fully automatic | Packaging Details: | Seaworthy packaging for the corer is shipped in a 40ft container. |

| Supply capacity: | Annual output of 100 core cutting machines | port: | Shanghai |

| Core Components Warranty: | 1 year | Applicable industries: | Transformer manufacturing, silicon steel slitting, CRGO steel slitting |

| strength: | 20, 30, 35KW | Core components: | PLC, engine, motor, gear |

| Coil width(mm): | 1000 - 1250 mm | Coil inner diameter (mm): | 480 - 520 mm |

| Width slitting error (mm): | 0 - 0.1 mm | Weight (kg): | 20000 |

| Certification: | EU standard | Warranty: | 1 year, 1 year |

| CNC system: | delta | Material: | Silicon steel |

| place of origin; place of origin: | Jiangsu, China | Slitting thickness (mm): | 0.23 - 0.5 mm |

| Showroom location: | not any | payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram |

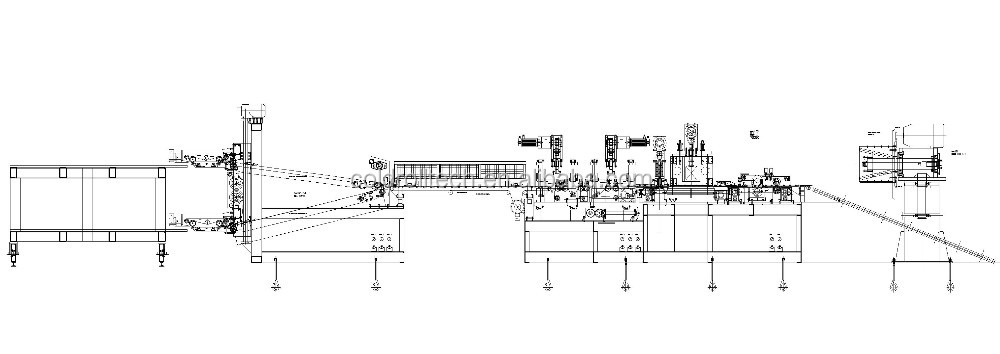

| Dimensions (L*W*H): | 12.6*6.5*2M | Line size: | 17.5mx 4.0mx 2.5m |

| brand: | HS | application: | transformer |

| Health status: | new | Mechanical test report: | if |

| After-sales service provided: | Engineers can repair machinery overseas |

Stepping lap core cutting machine transformer core wire

Product Description

This line is a fully automatic transformer core cutting line, suitable for V-free silicon wafers and punching of different shapes, including stepped lap cores. The line adopts servo motor feeding, servo motor punching, PLC control, and the screen can be set to touch screen. After cutting, the different shaped pieces are separated and placed in an orderly manner.

|

thing |

HJX300 |

HJX400 |

HJX600 |

|

Coil weight |

1000kg |

1000kg |

1000kg |

|

CRGO coil width |

30-330mm |

40-440mm |

60-660mm |

|

thickness |

0.23-0.35mm |

0.23-0.35mm |

0.23-0.35mm |

|

length accuracy |

±0.2mm |

±0.2mm |

±0.2mm |

|

cutting burrs |

≤0.02mm |

≤0.02mm |

≤0.02mm |

|

HMI |

10.4” touch screen |

10.4” touch screen |

10.4” touch screen |

|

total power consumption |

20KW |

30KW |

35KW |

|

Line size |

17.5mx 4.0mx 2.5m |

17.5mx 4.2mx 2.5m |

17.5mx 4.5mx 2.5m |

|

total gross weight |

16 tons |

17 tons |

19 tons |

core cutter

main ingredient

Double head hydraulic uncoiler

Speed control board with sensor in buffer pit

Servo feeding device

Pneumatic servo positioning V-groove machine

Pneumatic punching machine

Pneumatic 135° (or -45°) shearer (adjustable to 0°)

Pneumatic 45° Shearer

Servo rail positioning device

Belt conveyor with safety guard

Automatic Stacking Collection Conveyor

Product stacker

Operation control cabinet

Machine Features

Fully automatic line for different core cuts

Servo feeding, punching, with step lap function

High speed, high precision and easy operation

Centerline positioning, automatic stacking

International famous brand electric pneumatic components

our service

Customized machine one-stop service

Overseas installation operation training

One year warranty for the whole machine

Lifetime technical support

core cutter

core cutter

Other Products

-

$350000.00 / set

$350000.00 / set -

$120000.00 / set

$120000.00 / set