High Quality 4 Hole 10*7 Inch Concave ATV&UTV Aftermarket Wheels

-

Supplier: Qingdao Forcar Motorsport Co., Ltd. -

Region: Shandong, China -

Contact: Mr Bruce Liu -

Price: $30.00 / 80 - 299 pieces

$20.00 / >=300 pieces -

Min. Order: 80 pieces

| market: | Global | Certification: | TUV/JWL/VIA/SFI/ISO16949,TUV/JWL/VIA/SFI/ISO16949 |

| Numbering: | FCAM611 | Hole: | 4,4 hours |

| alien: | -15.5mm | width: | 7 inch |

| design: | custom design | payment terms: | L/C, T/T |

| size: | 10*7 inch | finishing: | Black |

| diameter: | 10 inches | Material: | Aluminum A356&A356.2 |

| Packaging Details: | International standard box; plastic bag; protective bag; foam | color: | Black |

| car model: | ATV & UTV | Warranty: | lifetime |

| Package preview: | port: | Qingdao/Ningbo/Shanghai port | |

| place of origin; place of origin: | Shandong China | Supply capacity: | 500,000 pieces per year |

| brand: | car in front | Name: | alloy wheels |

| Polycarbonate: | 101.6mm | MOQ: | 100PCS |

| process: | cast rim |

High Quality 10*7 Inch Concave 4 Hole ATV&UTV Aftermarket Wheels

If you want to see more rims click on the photo

This isgraysonfromShandong Fuka Racing Group Corporation. Forcar Motorsport Wheels and Forcar Motorsport design team has more than 10 years of experience in alloy wheel design and manufacturing, which has won the trust and praise of all customers. We can also provide special service for alloy wheels, alloy wheels, auto alloy wheels, auto wheels, rims, rims, plates, OEM. Allow me to briefly introduce as follows:

Forcar aluminum A356.2 cast and T6 forged alloy wheels in sizes from 10" to 28" with VIA, JWL, TUV, ISO, DOT certificates;

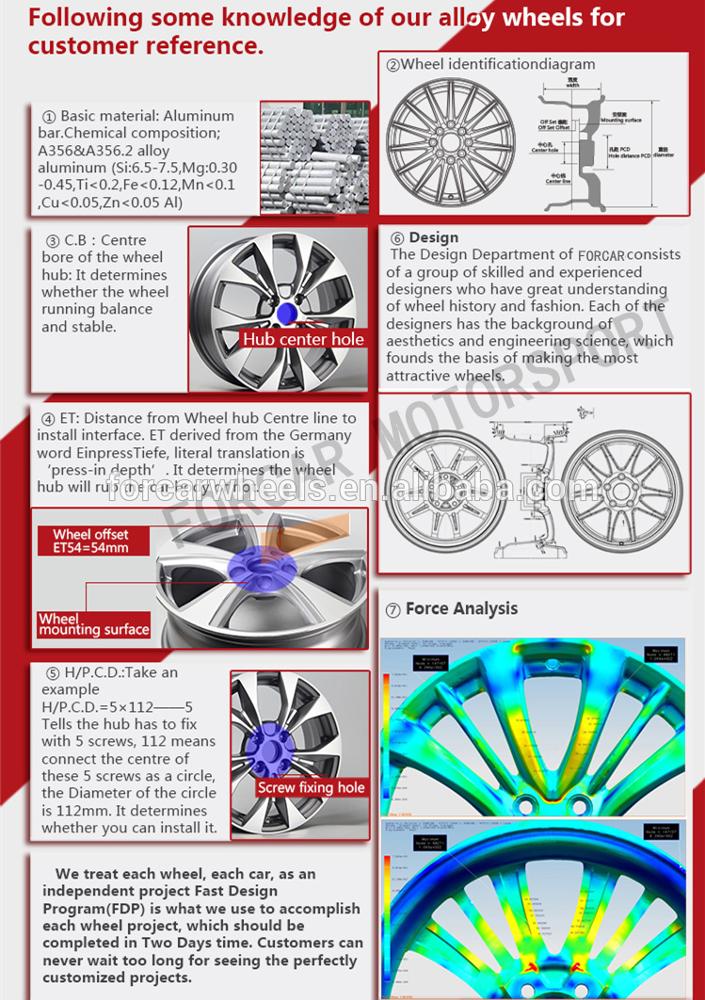

1. Chemical composition: A356&A356.2 alloy steel (Si 6.5-7.5, Mg 0.30-0.45, Ti<0.2, Fe<0.12 Mn<0.1 Cu<0.05 Zn<0.05 Al)

2. Finishes: Black, Silver, Bronze, Matte Black, Grey, Ultra Black, Ultra Silver, Machined Face, Machined Lip, Color Line, Chrome Plated, Vacuum Chrome Plated, Anodized, Fully Polished, Milled, Sandblasted , two-color, etc.

3. Process: low pressure, gravity casting, forging

4. Quality assurance: ISO/TS 16949:2000 quality system, German TUV, American SFI, DOT, Japanese VIA, JWL, ISO 9001:2008 quality system, national compulsory "C" certification

1. Design according to customer's samples or photos;

2. Make new designs according to different wheel patterns or concepts;

3. Carry out original design based on customer sketches or concept drawings;

4. Automobile assembly inspection;

5. Strength simulation and optimization before mold development

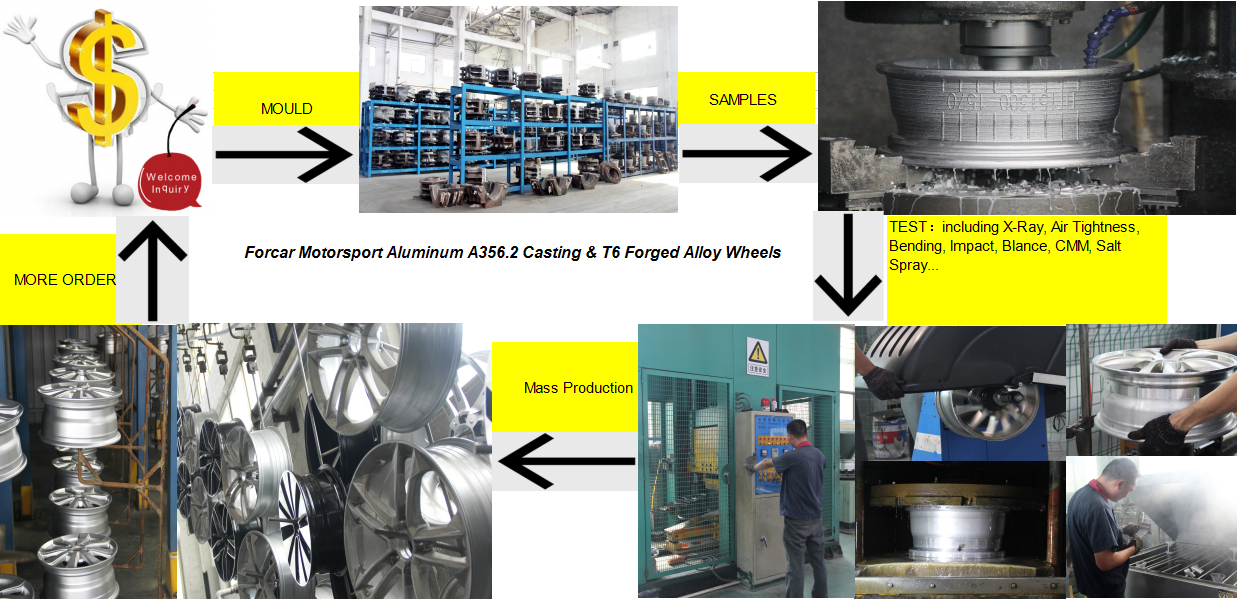

Rim sample or picture→deposit→drawing→mold→production→wheel sample→test (strict quality control including X-ray, airtightness, bending, impact, whitening, CMM, salt spray...)

Facilities and capacity

Testing before packaging

Packing and loading: international packing carton; poly bag; protective bag;

-

New sports version of four-wheeled motorcycle, scenic desert ATV, all-terrain kart, large power

-

Jantes 10 12 14 Inch Concave ATV & UTV Wheels For Sale

-

Amphibious All-Terrain Vehicle for Rescue and Flood Rescue

-

Hot sale emergency anti-flood land amphibious all-terrain vehicle

-

Makes 14" ATV and UTV Aftermarket Wheels

-

Concave 12/14" ATV&UTV Aftermarket Alloy Wheels

-

China High Quality Utility Buggy Quad Bike Off Road Gasoline Road Legal 400CC Go Karts Farm UTV With EPA For Sale

-

All Terrain Vehicle Dirt Vehicle Road Legal Dune Gas Power ATV UTV 200cc Kids Quad Utility Vehicle Sports Cart

-

Wholesale Jova Blanks China 18 Inch Rim Motorcycle Rim Car Wheel Ipw

-

Concave ATV & UTV 10 Inch 4 Hole Aftermarket Auto Rim

Other Products

-

$275.00 - $300.00 / piece

$275.00 - $300.00 / piece -

$20.00 - $30.00 / piece

$20.00 - $30.00 / piece -

$90.00 - $500.00 / piece

$90.00 - $500.00 / piece -

$48.00 - $300.00 / piece

$48.00 - $300.00 / piece -

$32.00 - $40.00 / piece

$32.00 - $40.00 / piece -

$33.00 - $35.00 / piece

$33.00 - $35.00 / piece -

$200.00 / piece

$200.00 / piece -

$20.00 - $30.00 / piece

$20.00 - $30.00 / piece