RY-100-5S 3 Axis 4 Axis 5 Axis CNC Metal Cutting CNC Engraving Machine Metal DIY

-

Supplier: Shenzhen Yu Diao Cnc Technology Co., Ltd. -

Region: Guangdong, China -

Contact: Mr fengsheng Hong -

Price: $15000.00 / 1 - 4 sets

$14000.00 / 5 - 9 sets

$13000.00 / >=10 sets -

Min. Order: 1 set

Product details

| brand: | determined | System Configuration: | Taiwan SynTech/Japan MITSUBISH |

| Spindle speed (rpm): | 24000 rpm | Mechanical test report: | if |

| Positioning accuracy (mm): | 0.02mm | Maximum processing speed: | 6 m/min |

| Core component warranty: | 1 year | Warranty: | 1 year |

| port: | Shenzhen | Package preview: | |

| X, Y, Z: | 120*120*100mm | positioning accuracy: | ±0.005/300mm |

| Weight (kg): | 100 | Packaging Details: | In accordance with international logistics standards |

| Main selling points: | competitive price | Maximum operating speed: | 128m/min |

| Dimensions (L*W*H): | 400*400*400 | Marketing Type: | normal product |

| Spindle power (kW): | 1 | Repeatability (X/Y/Z) (mm): | ±0.02 |

| Spindle speed range (rpm): | 1 - 24000 rpm | aspect: | 400*400*400mm |

| place of origin; place of origin: | Guangdong, China | Video shipment inspection: | if |

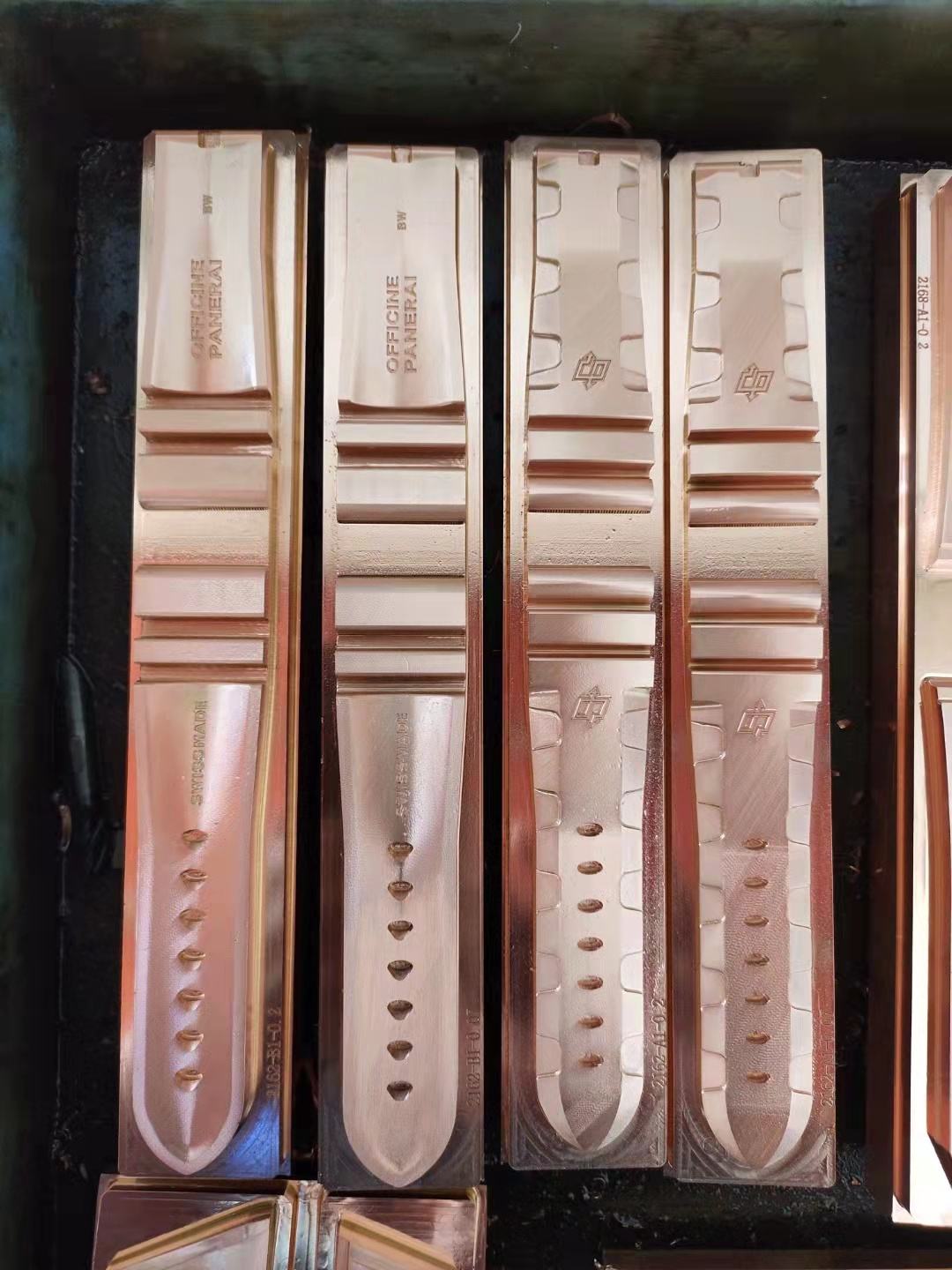

| Core components: | PLC, bearings, gearboxes, motors, spindles | application: | 3c products, other applications, hard materials, 3C accessories, precision molds, precision electrodes, medical industry |

| Health status: | new | Showroom location: | Vietnam, Peru, Thailand, Japan |

| payment terms: | Western Union, T/T, MoneyGram | Supply capacity: | 100 sets per week |

| Repeatability: | ±0.02 | Table size: | 100*100mm |

Product Description

1. The casting structure is stable, reasonable and beautiful. The cast iron of our company adopts HD250 grade casting, which has time aging and annealing aging, which ensures that the cast iron body is stable without deformation and durable. 2. The main parts of the fuselage adopt the first and second configuration parts imported from the same industry: for example: the guide rail adopts Taiwan Shangyin or Yintai or ABBA precision grade guide rail; the screw rod is Japan NSK, THK or Germany Rexroth (Rexroth); The first generation of bus absolute value control system and integrated drive; the servo motor adopts the high inertia of Panasonic servo motor in Japan; the wire adopts Japanese wire and customized wire;

Applicable industries: ceramics, glasses, fiberboard, mobile phones, molds, hardware (hardware accessories in various industries), glass, auto parts, electronic cigarettes, smart wear, PCD circuit boards, accessories, handicrafts, die-casting parts, jewelry, seal signs,

One | Machine tool technical parameters: | ||||||||

1 | The fuselage and all parts are made of nano castings | ||||||||

2 | table size | 130×130mm | |||||||

3 | T-slots (width x number x spacing) | / | |||||||

4 | maximum load | 10KG | |||||||

5 | feed height | 240mm | |||||||

6 | Spindle end face to workpiece distance | 0-170mm | |||||||

7 | Three-axis travel X/Y/Z | 200/170/170mm | |||||||

8 | Spindle diameter | Ǿ62mm | |||||||

9 | Spindle speed | 30000 rpm/60000 rpm | |||||||

10 | Spindle motor power | 2.5KW | |||||||

11 | Spindle magazine capacity | 8 | |||||||

12 | Tool change time | 5S | |||||||

13 | Spindle taper | Ǿ6mm | |||||||

14 | /tool magazine | / | |||||||

15 | Rapid movement rate X/Y/Z | 12/12/12 m/min | |||||||

16 | processing speed | 1-6 m/min | |||||||

17 | positioning accuracy | ±0.01/300mm | |||||||

18 | Repeatability | ±0.01/300mm | |||||||

19 | Processing Surface Accuracy | ≤Ra3.2 | |||||||

20 | Precision | ±0.02mm | |||||||

twenty one | Optional four-axis five-axis | Yes | |||||||

twenty two | A axis rotation angle | ±105 degrees | |||||||

twenty three | Fifth axis C axis rotation angle | 360 degrees | |||||||

twenty four | Five-axis linkage mode | 5-axis follow-up | |||||||

25 | Operating Voltage | 220V/60HZ | |||||||

26 | Machine size (length*width*height) | 400×400×400mm | |||||||

27 | weight | 100KG | |||||||

Second | Machine tool configuration details Brand parameters: | ||||||||

1 | System Configuration | Taiwan LNC M3000D | |||||||

2 | Spindle | 2.5KW high-precision, high-speed, high-quiet oil-cooled spindle | |||||||

3 | Ball screw rod | China grinding grade | |||||||

4 | Linear Guides | China high precision rail H25 | |||||||

5 | Servo unit | Easy Servo Motor | |||||||

6 | Wire Bearings | Taiwan TPI precision grade bearings | |||||||

7 | switching power supply | Mean Well Taiwan | |||||||

8 | electric switch | CHINT | |||||||

9 | converter | * Square Converter | |||||||

Shenzhen Yudiao CNC Technology Co., Ltd.

Contact: Hong Fengsheng

Contact number: 0086 13421359966 (WeChat or WhatsApp same number)

Address: Room 101, Building 1, No. 13, Dakang Road, Dakang Community, Yuanshan Street, Longgang District, Shenzhen

VIEW MORE

You may like

-

Price concessions CNC router mechanical cutting and engraving 3d CNC router

-

ATC CNC Mini Metal Milling Machine

-

3D CNC engraving machine

-

Electric Spindle CNC Milling Machine

-

High Precision 5 Axis Milling Machine

-

Milling Machine, Multi-axis CNC milling machine.

-

Automatic 3 axis high spindle speed metal mold CNC milling engraving machine for mold fine/finishing

-

PURUITEKEJI 3018 Pro CNC Mini Router CNC Woodworking Router

-

LEYO CNC Machining Milling Machine 5 Axis Vertical CNC Milling Center

-

Desktop CNC Router for Master Pattern Making