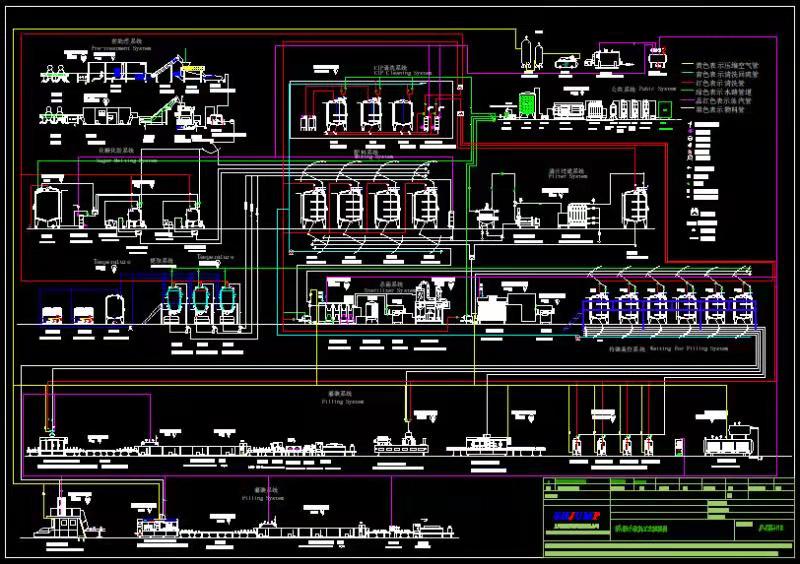

Ketchup Making System Machine Reverse Osmosis Water Mixing Homogenizer and Tin Can Filling System

-

Supplier: Shanghai Jump Machinery & Technology Co., Ltd. -

Region: Shanghai, China -

Contact: Ms May Feng -

Price: $440000.00 /set -

Min. Order: 1 set

Product details

| Mechanical test report: | if | Marketing Type: | normal product |

| Production capacity: | 1-30 tons/hour | Core components: | PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump |

| Core component warranty: | 1 year | Voltage: | 380v |

| port: | Shanghai | Warranty: | 1 year |

| Types of: | sauce machine | Material: | stainless steel 304 |

| Local service location: | Egypt, Canada, Turkey, Germany, Vietnam, Philippines, Saudi Arabia, Indonesia, Pakistan, Mexico, Russia, Thailand, Malaysia, Australia, Morocco, Kenya, Argentina, South Korea, Chile, United Arab Emirates, Colombia, Algeria, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan | application: | make ketchup, ketchup |

| Showroom location: | France, Vietnam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Thailand, Morocco, South Korea, Chile, Colombia, Algeria, Sri Lanka, Bangladesh, Kazakhstan, Ukraine, Uzbekistan, Malaysia, Australia | place of origin; place of origin: | China Shanghai |

| Package preview: | Total power: | 80 kW | |

| payment terms: | L/C, T/T | Video shipment inspection: | if |

| State of health: | new | Supply capacity: | 50 sets per year |

| Certification: | CE certification | strength: | by capacity |

| Packaging Details: | Wooden box packaging plastic wrap | Processing type: | Tomato paste dilution and filling machine |

| Applicable industries: | Manufacturing plants, food and beverage factories, food stores, food and beverage stores, fruit processing customers | Dimensions (L*W*H): | by capacity |

| model: | JP-MY-0803 | After warranty service: | On-site maintenance and repair services |

| weight: | 1000 kg | After-sales service provided: | On-site installation, commissioning and training |

| Automatic type: | fully automatic | brand: | jump |

| Automatic level: | automatic |

Product parameters

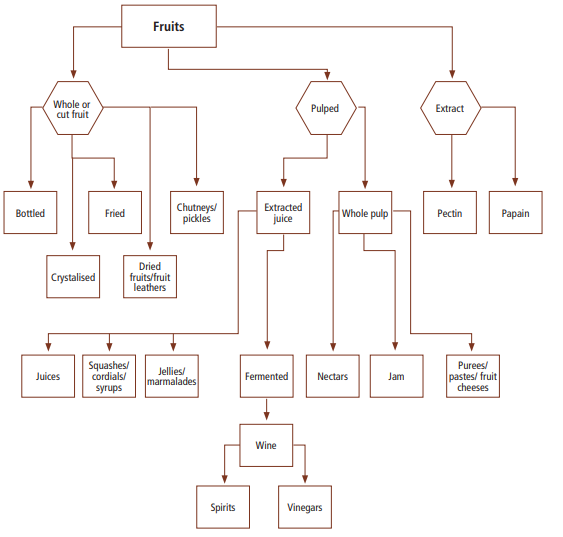

Overview of fruit processing projects (custom data contact us) | ||

capacity | 100kg-10t per hour | |

raw material | Fresh fruit: mangoes, pineapples, tomatoes, berries, apples, bananas, figs, papayas, pears, etc. | |

finished product | Juices, fruit purees, concentrated juices, jams, dried and frozen fruits, etc. (For more fruit product choices, see the end of the article) | |

Final product Brix | 7-12 brix (juices), 22-36 brix (purees and jams), 65-75 brix (concentrates) | |

Voltage | 380V 50Hz/ 110V 60hz 415V 50Hz (can be adjusted according to the customer's national standard) | |

energy consumption | Energy-saving type, about 100-500kw, | |

operator required | About 6-20 people | |

The main material of the machine | SUS304 or SUS316 | |

cooling water consumption | About 80-3200M3 | |

workshop space required | About 500-1500M2 | |

steam consumption | About 300-5000kg/H | |

place of origin; place of origin | China | |

manufacturer history | 30 years | |

Warranty | 12 months after commissioning | |

Further end product and package options are available below | ||

What products can we provide? We provide all kinds of fruit processing production lines! Machinery for the manufacture of:

Juices, syrups, pulps, purees, pastes, concentrates, nectars, jams, jellies, jams, pumpkins, etc.

Bottled fruit, dried fruit, fried fruit, crystallized fruit, pickled fruit, etc.

Fruit extract, fruit powder, pectin, essence, oil, etc.

Fruit wine, vinegar, etc.

Fruit strips, fruit cakes and other fruit snacks.

Description and pictures of key machines for reference

(The machine list is customized according to your detailed requirements, please contact us for accurate information)

key machine | illustrate |

Bucket elevator | 1. The smooth bucket structure does not pinch fruit, suitable for tomatoes, strawberries, apples, pears, apricots, etc. 2. Stable operation, low noise, frequency conversion speed regulation. 3. Anti-corrosion bearing, double-sided seal. |

blower | 1 For washing fresh tomatoes, strawberries, mangoes, etc. 2 Special surfing and bubbling design to ensure thorough cleaning and reduce damage to fruits. 3 Suitable for many kinds of fruits or vegetables, such as tomatoes, strawberries, apples, mangoes, etc. |

grinder | For crushing fruit into pieces and further pulping |

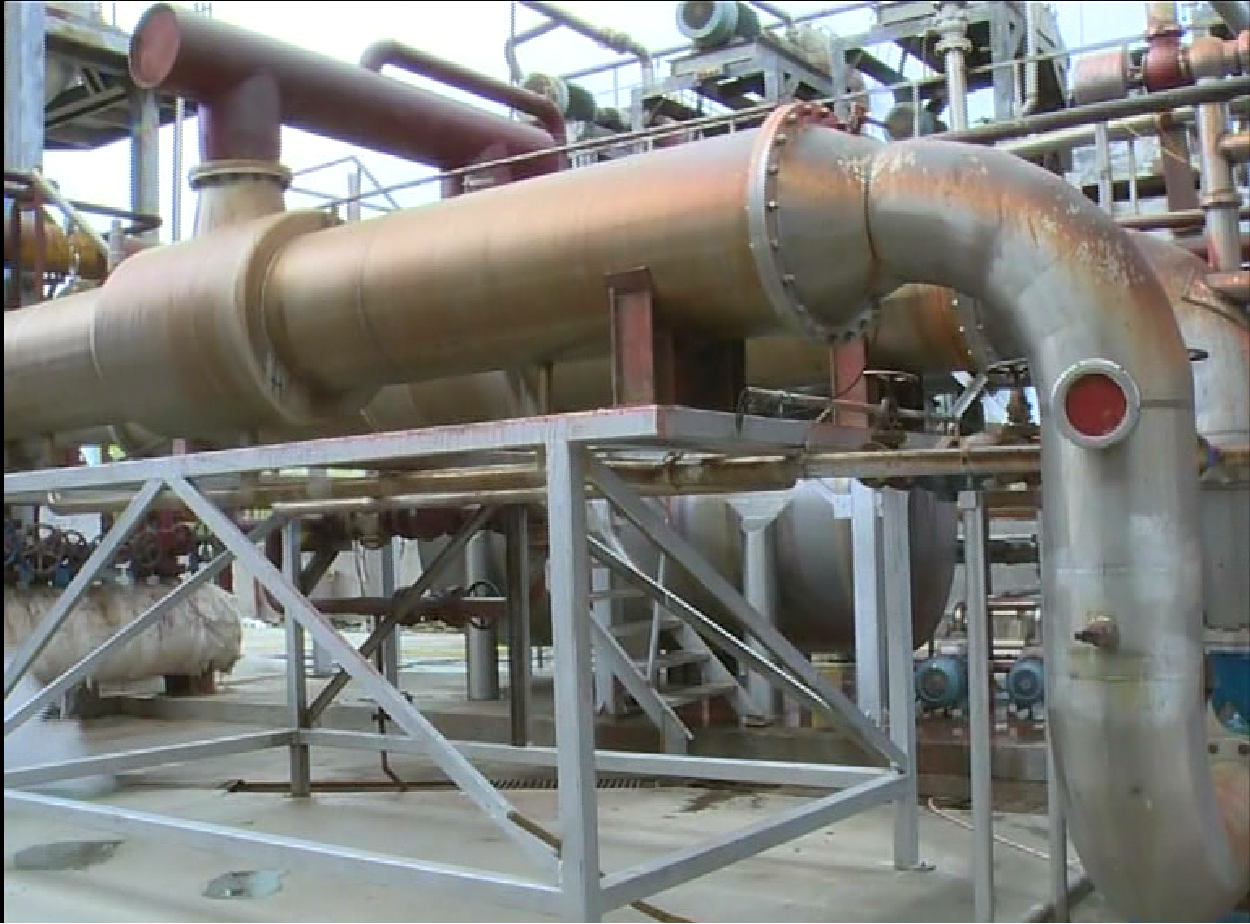

1. Inactivate enzymes and protect the color of the paste. 2. Automatic temperature control, adjustable air outlet temperature. 3. Multi-tube structure with end caps 4. If the effect of preheating and deactivation fails or is not enough, the product flow will automatically re-enter the pipeline. | |

1. It is widely used in the extraction and dehydration of various acini, drupe and vegetables. 2. The unit adopts advanced technology, high pressure, high efficiency, high degree of automation, and convenient operation and maintenance. 3. The extraction rate can reach 75-85% (based on raw materials) 4. Less investment, high efficiency | |

Evaporator | 1. Adjustable and controllable direct contact heat treatment unit. 2. The shortest possible residence time, a thin film along the full length of the tube reduces retention and dwell time. 3. Specially designed liquid distribution system to ensure correct pipeline coverage. The feed enters from the top of the calandria The distributor ensures the formation of a thin film on the inner surface of each tube. 4. The steam flow and the liquid flow in parallel, and the steam drag improves the heat transfer. steam and remaining liquid Separation in a cyclone. 5. Efficient separator design. 6. Multi-effect arrangement provides steam economy. |

1. The unit is composed of a product receiving tank, a superheated water tank, a pump, a product double filter, and a tubular superheater Water generation system, tube-in-tube heat exchanger, PLC control system, control cabinet, steam inlet system, valves and sensors, etc. 2. Introduce Italian technology and meet European standards 3. Large heat exchange area, low energy consumption and easy maintenance 4. Adopt mirror welding process to keep the pipe joints flat 5. Automatic backtracking for insufficient sterilization 6. CIP and automatic SIP are provided together with aseptic filling machine 7. Real-time control of liquid level and temperature | |

1. Suitable for aluminum foil (Bag-in-drum&Bag-in-box) composite aseptic bags of 5L-220L. 2. It is composed of aseptic filling head, precision electronic balance, PLC control system, steam barrier and protection system, and operation platform 3. The filling room is protected by steam and always kept in a sterilized state. 4. Fully automatic SIP and CIP available |

Our advantage

only one!

We are a unique supplier in China and even in the world. We have a machinery manufacturing factory, we have a juice manufacturing factory, and we have a product trading company.

We are the only ones who can provide you with:

Full line of machines

+Machine running experience

+Factory management experience

+ Product marketing experience

+ Full chain material supply

(concentrated juice, packaging material barrels/aseptic bags/bags, etc., canning machines, etc.)

Value-added services!

Layout Design Services

We carry out precise processing line layout design according to the customer's factory size; if required, we can carry out the layout design of the whole factory. All pipes, cables, connections will be accurately calculated.

Installation and commissioning and labor training services

After receiving the confirmed order and deposit, we immediately start to apply for a visa to your country; when the machine arrives at your factory, our engineers are ready to start the commissioning service. Our engineers will go to your factory to install and adjust the processing line to achieve normal production in the shortest time. Our engineers are responsible for teaching workers how to operate, clean, maintain and repair all machines until workers can operate the processing line well.

Pilot production and formula research

We have our own laboratory and mini processing line. Before your line goes into production, we can conduct trial production in our laboratory, and we can also provide you with formulation studies if required.

VIEW MORE

You may like

-

Commercial Electric Spice Grinder Dry Food Powder Grinder Making Machine Chilli Pepper Spice Granule Grinder

-

250g Electric Coffee Bean Grinder Chili Grinder Nut and Spice Grinder Spice and Sauce Maker

-

500g salt grinder, corn dispenser, spice grinder seasoning processing machine

-

CM-02A 100g CE Commercial Spice Grinder

-

Factory Supplier Electric Spice Grinder Spice Powder Grinder

-

Industrial Salt Electric Chili Grinder Spice Grinding Packing Machine

-

Industrial food sauce mixer sauce cooking mixer sandwich pot machine sauce sandwich pot industry

-

CM-10B 500g Hot Sale Commercial Electric Herb Spice Grinder

-

Hot sale factory direct sale dry_spice_grinder grinders_spice spice grinder business supplier

-

High Quality Onion and Garlic Powder Grinder

Related Search

reverse osmosis water filter system

reverse osmosis water purifier

2 stage reverse osmosis water filter suppliers

water treatment reverse osmosis system

reverse osmosis system

commercial reverse osmosis system

pyrolysis machine with recycling water cooling system

reverse osmosis fresh water generator

reverse osmosis plants

making pipes machine