Space-saving automated single column stacker ASRS Single Column Stacker Crane

-

Supplier: Wangu Intelligent Control Precision Manufacturing (Guangzhou) Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Cindy Lina -

Price: $600.00 /unit -

Min. Order: 1 unit

| model: | WG-SC-010 | place of origin; place of origin: | China |

| feature: | Simple, safe and convenient operation | Advantage: | high efficiency |

| usage: | Automatic storage and retrieval | Control Method: | Programmable Controllers |

| scale: | relaxing work | Supply capacity: | 100 sets per month |

| Package preview: | Running speed: | 0-200 M/min (adjustable) | |

| Certification: | ISO9001/CE | application: | Warehouse or logistics center |

| capacity: | 20-200kg | Packaging Details: | Standard export packing, plywood carton |

| high: | up to 26m | port: | Shenzhen, Guangzhou |

| payment terms: | Western Union, T/T, MoneyGram | product name: | Single column stacker |

product introduction

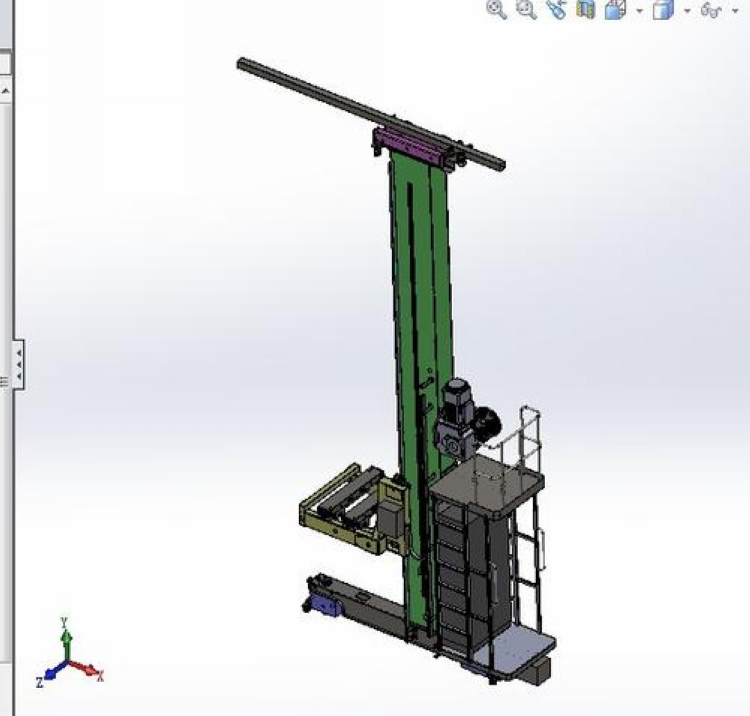

Our stacker is a custom-made automatic pallet stacking/retrieval device for automated warehouse storage solutions.

It performs movement in three directions in the roadway,

Horizontal reciprocating linear motion: XX direction;

Vertical lifting movement: YY direction: left and right,

The forks make telescopic movements in the ZZ direction to complete the loading and unloading of the goods.

Reference parameters of our stacker

|

product |

AS/RS |

|

Material |

Steel Q235 |

|

Loading |

500-6000kg/layer |

|

upright |

Single column or customized on request |

|

beam |

Customized on request |

|

Stacker height |

Customized on request |

|

color |

blue, orange, gray or customized |

|

Finish |

Anti-corrosion, outdoor powder coating, robot welding |

|

Installment instructions |

usable |

|

warehouse stacker |

||

|

Ordinary stacker Load capacity: 500-1500kg Height: 7-24m Speed: 160m/min |

Double station stacker Load capacity: 2000-6000kg Height: 24-35m Speed: 120m/min |

Single Mast Stacker Load capacity: 20-50kg Height: 3-6 meters Speed: 200 m/min |

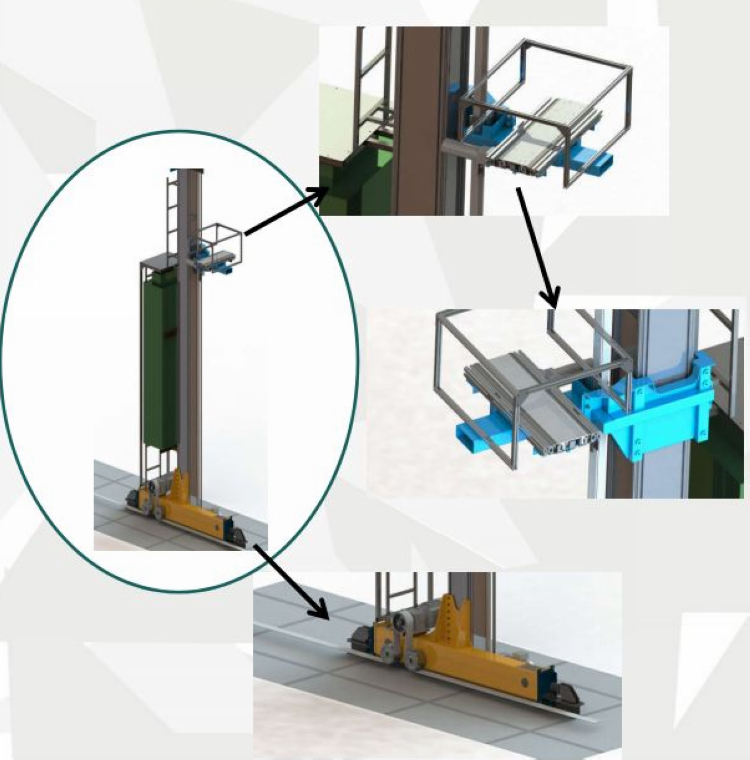

Description of the components of our stacker

1. Main steel structure

2. Walking drive device

3. Lifting device

4. Forks and wheels

5. Safety device

6. Control system/PLC

Advantages of our stackers

1. Can make full use of warehouse space/height

2. Save space

3. Reduce labor costs

4. Reduce the error rate of manual operation

5. Improve work management, etc.

More pictures of our stackers

-

500KG load-bearing folding warehouse storage cage wire mesh container cage

-

Metal Storage Rack Storage Rack Storage Rack Heavy Duty 4 Tiers Factory Warehouse Shelves

-

Shelf warehouse storage medium-sized 300kg large-span shelf system storage shelf metal heavy-duty shelf wheel storage rack

-

Medium-sized warehouse European pallet rack heavy metal shelf metal storage stacking rack

-

Modern grocery display store beveled shelf steel wood display wooden gondola shelf

-

Home or Market Store Miscellaneous Shelves Steel Wood Shelves With Cabinet Shelves Furniture

-

LIJIN factory direct sales light medium storage rack