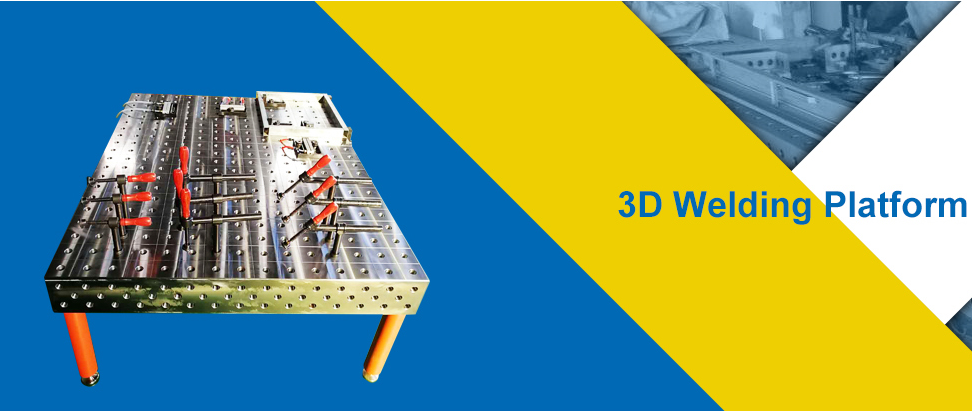

3D soldering station, jigs and fixtures in stock

-

Supplier: Hebei Forward Measuring Tools Co., Ltd. -

Region: Hebei, China -

Contact: Ms Amy Wang -

Price: $99.00 /piece -

Min. Order: 1 piece

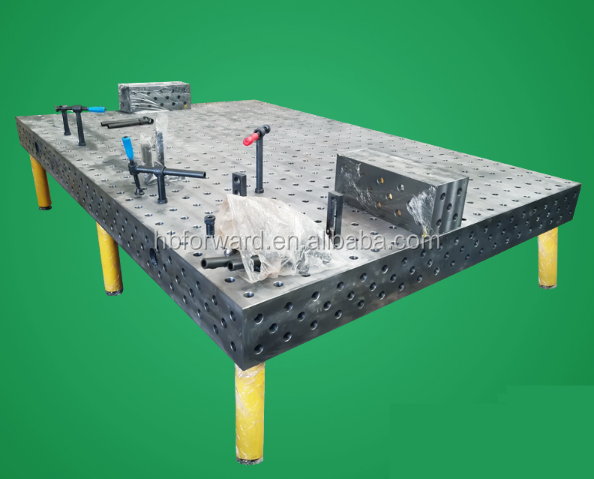

| Certification: | GS | Gridlines: | 100*100 |

| Sheet thickness: | 25mm | Hole distance: | 100±0.03 |

| payment terms: | T/T, Alibaba | brand: | forward |

| Warranty: | 1 year | place of origin; place of origin: | Hebei |

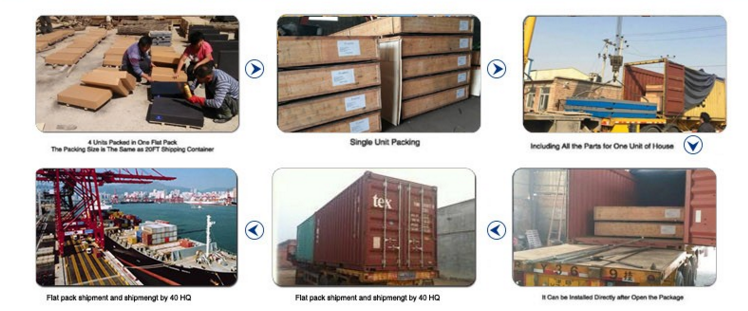

| Material: | HT300 | Packaging Details: | Plywood boxes |

| Supply capacity: | 1200 pieces per day | Flatness: | 0.05mm/1㎡ |

| Casting process: | chemical hard sand casting | port: | Tianjin |

| Roughness: | Ra1.6 | weight: | 450 kg |

| Customization support: | OEM production | model: | 4002 |

| series: | D28 |

3D Soldering Station with Stock Fixtures and Fixtures

3D Welding Workbench: Five working surfaces where positioning parts can be installed. It can also be extended by any of its five work surfaces.

• Divided by material: steel welding station (Q345) and casting welding station (HT300).

• It is divided into D28 series and D16 series according to its hole diameter.

Diagonal grid: D28 is 100*100mm; D16 is 50*50mm.

Supports: legs, steel frames and hydraulic lift boxes, upon request.

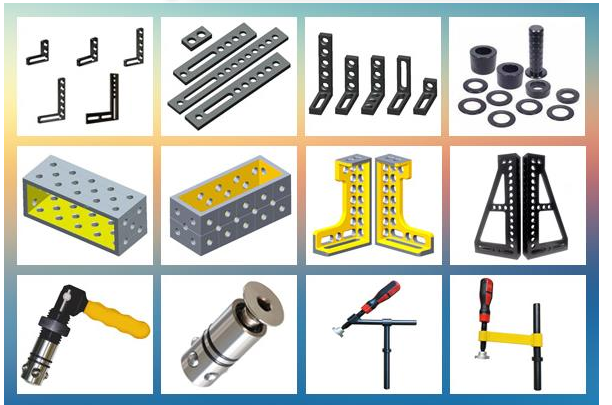

Components you can equip when you choose:

1. Support tools: U-shaped cube box, L-shaped cube box, angle support, angle gauge

2. Locating spare parts:

3. Clamping and fixing tools

4. Lock the workpiece spare parts

5. Auxiliary tools

feature:

• During assembly or welding, almost all workpieces can be held precisely at certain points or surfaces by means of locators, adapters, fasteners and supports.

• Inaccurate workpiece dimensions can be adjusted during pre-machining.

• It is easy to use the parts already in the workshop and simulate the assembly of the workpiece through CAD.

-

Measuring Tool High Precision Radius Gauge R1-R52 Radius Gauge

-

Portable Internal Combustion Tamping Machine

-

Hydraulic petrol engine turnout tamping machine for track turnout tamping work

-

Rail Tamping Machine Portable Rail Tamper for Railway Maintenance Work

-

Digital rail cant device used for measuring Track superelevation gauge railway maintenance equipment

-

Third rail gauge Contact rail ruler for railway inspection

-

Railway track measuring equipment rail Station Platform Clearance Gauge

-

Railway Joint Gap Measuring Device for Railway Track Joint Clearance Measurement

-

Rail Web Width Measuring Gauge

-

Railway Square Ruler T Shaple

Other Products

-

$38.00 / piece

$38.00 / piece -

$2.20 / piece

$2.20 / piece -

$53.00 / piece

$53.00 / piece -

$169.00 / piece

$169.00 / piece