RESEM 10T/d Convert Waste to Energy Used Tire Pyrolysis Recycling Machine

-

Supplier: Shangqiu Ruixin General Equipment Manufacturing Co., Ltd. -

Region: Henan, China -

Contact: Ms. luisa zhang -

Price: $60000.00 /set -

Min. Order: 1 set

| Single package size: | 1750X260X260 cm; | Power(W): | 20KW; |

| Delivery Detail: | 0 days after payment; | Heating material: | Coal, charcoal, fuel gas, fuel oil; |

| Thickness of reactor: | 14mm&16mm; | Warranty: | 1 Year; |

| Weight: | 35-40 Ton; | Brand Name: | RESEM; |

| Place of Origin: | Henan China (Mainland); | Certification: | ISO9001:2008/CE; |

| Type: | Pyrolysis; | Raw material: | Waste tyres, scrap plastic, waste rubber; |

| Package Type: | Naked Package; | Power in total: | 22-30Kw; |

| Life: | 6 years; | Mode of cooling: | Water cooling; |

| Rotate speed of reactor: | 0.4--0.8 turn/minute; | After-sales Service Provided: | Engineers available to service machinery overseas; |

| FUEL OIL: | 45-50%; | Voltage: | 380V; |

| Size of reactor: | D2600mm L6600mm; | Dimension(L*W*H): | 2600mm*6600mm; |

| Single gross weight: | 35,000 KG; | Selling Units: | Single item; |

| Condition: | New; | Material of reactor: | Q245R/Q345R boiler plate; |

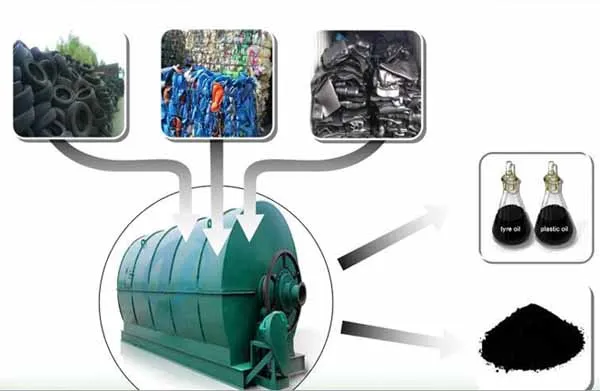

Waste Tires to oil pyrolysis plant design

Working process:

Pyrolysis machine specification

| Items | Contents | |||||

| Raw material | Waste tyres, scrap plastic, waste rubber | |||||

| Structure form | Horizontal | |||||

| Model | HA-5-PT | HA-8-PT | HA-10-PT | HA-15-PT | 2HA-20-PT | |

| Size of reactor | D2000mm | D2200mm | D2600mm | D2800mm | D2600mm | |

| L4500mm | L6600mm | L6600mm | L7700mm | L6600mm | ||

| 24-hour capacity | 5 tons | 8 tons | 10 tons | 12 tons | 20 tones | |

| Operating pressure | Constant pressure | |||||

| Heating material | Coal, charcoal, fuel gas, fuel oil | |||||

| FUEL OIL | 45-50% | |||||

| CARBON BLACK | 30% t0 35% | |||||

| STEEL WIRE | 10% to 15% | |||||

| GAS | 10% to 12% | |||||

| Material of reactor | Q245R/Q345R boiler plate | |||||

| Thickness of reactor | 14mm&16mm | |||||

| Rotate speed of reactor | 0.4--0.8turn/minute | |||||

| Mode of cooling | Water cooling | |||||

| Power in total | 22-30Kw | |||||

| Life | 6 years | |||||

Given below wastes that you can recycle:

1. Waste Plastic

2. Rubber

3. Plastic or rubber parts from vehicles

4. House garbage, Plastic cable, Plastic bag, Sole

5. Mixed plastic (HDPE, LDPE, PE, PP, Nylon, PS, ABS etc.)

6. Leftovers of paper, Submarine cable

7. Mixed waste plastic from waste paper mill

8. Multi Layered Plastic

9. Waste engine oils etc.

Pyrolysis machine final production

Shangqiu Ruixin Genaral Equipment manufacturing Co., Ltd is a high-tech enterprises integrating scientific research, production, sales, service, import and export.

Since our company was founded in 1999, the company has gained successfully 3 patents and more than 24 utility model patents; completed the "ISO9001 international quality system certification", "ISO14001 Environmental Management System Certification Cert ","CE certification". Our company was named municipal enterprise technical centers, The top ten most innovative technology-based business model of Henan Province, " Henan Province, energy saving technology innovation demonstration enterprise certificate "," Shangqiu Environmental Protection Special Equipment Manufacturing Industry Association unit "and other honorary titles.

RESEM has ONE sub-company named Henan Clean Smart Environmental Technology Co.,ltd, and THREE manufacturing factories in China, we also have 4 foreign branches all over the world. We have our own factory and professional team, which can provide you more perfect and widely after-sales service.

RESEM has passed the ISO9001:2008 and the ISO14001 2004, which marks the great progress it has made in the quality of the products and environmental protection. RESEM’ factory covering an area of 30000 square meters. We have 35 professional engineers and skillful technicians with rice installation and commissioning experience. Monthly production capacity exceeds 20 sets. There are more than 300 staff members including the managements, the sales and the technical workers. All the staff work hard on the way to success on the purpose of to serve the customer, to develop the technology.

We have advanced and complete demo machine in our factory, And there are many pyrolysis plant projects around our company, It takes about one hour's drive from Zhengzhou Xinzheng International Airport to our factory. RESEM will be responsible for picking up customers. Welcome to RESEM to see our demo machine and running machine anytime.

National Patent

Shangqiu Ruixin General Equipment Manufacturing Co., Ltd. (RESEM), established in 1999, after 17 years of development, has obtained 6 national invention patents and 17 utility model invention patents, passed ISO9001 and ISO14001 international certification system, and built a wide platform for the Chinese petrochemical industry, ‘production and research integration’ field and ’military and civilian cooperation’.

RESEM 20 Tpd Tire Pyrolysis Project in Texas, USA

1. Professional service team to provide technical support for pre-sale, sale and after-sale.

2. We will provide installation instructions on your working site, test machines and provide training for your workers.

3. 12 months quality warranty for main machine.

4. 24 hours feedback response: solve your problems online or on your working site.

5. Accessories and spare parts are available at cost price all year round.

RESEM products mainly include Waste tire and waste rubber, plastic pyrolysis equipment; Crude oil, fuel oil, waste oil and lubricating oil Distillation equipment; Carbon black deep processing machine and tires crushing equipment. After purification, the oil quality will be improved. It can take place of diesel, and can be directly used in vehicles. And RESEM have exported more than 389 sets of equipment to many countries and areas, such as Turkey, Albania, Macedonia, Iran, Ecuador, Poland, India, Malaysia, and Bangladesh and so on.

RESEM 2017 New tech 10 tons Waste 0il Distillation Plant to Diesel

-

1-6 axis/shaft type rubber gasket cutting machine for gaskets or rubber rings

-

Rubber pressure bladder for Almex Eupno Beltwin vulcanizing presses

-

Metal Plastic Crusher Biaxial Pet Bottle Grinding Multifunctional Tire Shredder Tire Crusher

-

Factory Direct Sales Truck Radial Tire Retreading Machine/Tyre Retreading Equipment

-

Scrap Tire Sidewall Polishing Machine Circular Cutting Blade

-

Waste Tire Recycling Machine Tire Pulverizer Machine for Rubber Pulverizer

-

Scrap Big Truck Tire Sidewall Cutting Machine Mechanical Recycling Tire Cutting Machine Recycling Machine

-

open mixing mill

-

UT-A2100 Portable Heat Press Machine PVC Conveyor Belt Vulcanizing Machine Air-cooled Crimping Machine

-

Rubber floor tile vulcanizing machine/rubber floor mat making machine

Other Products

-

$58000.00 / set

$58000.00 / set