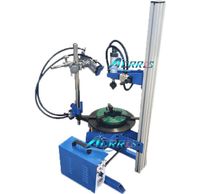

Rotary welding machine 100 kg

-

Supplier: Hitop Machinery Manufacturing Co. Ltd -

Region: Shandong, China -

Contact: Ms Li Amy -

Price: $735.00 /set -

Min. Order: 1 set

Product details

| Origin: | Shandong China | Applicable industries: | Clothing store, building material store, machinery repair shop, manufacturing plant, farm |

| Supply capacity: | 500 sets per month | Weight (kg): | 100 kg |

| aspect: | Depends on the model, 500*475*410 | Core component warranty: | 1 year |

| Rotating speed: | slowly | Main selling points: | portable |

| port: | Qingdao Port | Core components: | PLC, engine, motor |

| Marketing Type: | New Products 2020 | Warranty: | 1 year |

| weight: | 100 kg | Video shipment inspection: | not available |

| Showroom location: | Malaysia, Australia | Health status: | new, new |

| payment terms: | L/C, D/P, D/P, T/T | type: | Welding positioner |

| After-sales service provided: | Video technical support | color: | blue or customized |

| equipment: | 100kg servo welding positioner | product name: | welding locator |

| Speed mode: | Frequency conversion stepless speed regulation | usage: | welding positioning |

| Mechanical test report: | if |

Product parameters

Model | SH-CNC100 | input power | 220V |

Load capacity 0°/90° | 100Kg/50Kg | Rated Center of Gravity | 100mm |

Rated eccentricity | 100mm | table diameter | 400mm |

rotating electrical machine | 86 steps | Table speed range | 0.1-3rpm |

flip angle | 0~90° | Turning method | manual |

Table height(mm) | 512 | Dimensions (mm) | 520X575x512 |

product description

product description

The main structure of the 100 kg welding positioner of Shanghong Machinery is composed of a workbench, a manual turning mechanism, a control box, a geared motor, an electric control box and other parts. The workpiece is fixed on the worktable for rotation and tilting, so that the welding seam is in the most favorable welding position, so as to improve the welding quality and production efficiency, and reduce the labor intensity of workers.

Product Description

Rotation part:

A 2.2KW AC frequency conversion motor is selected with a worm gear reducer and a slewing bearing to drive the table to rotate. The gravity of the slewing bearing is partly stressed, which can more effectively protect the motor reducer and increase the service life.

Flip part:

A 3KW AC brake motor is selected with a worm gear reducer plus half teeth to realize the bipolar protection of the overturning part. One is the motor braking function, and the other is the self-locking function of the reducer. At the same time, the double half-tooth structure realizes more stable and safe overturning.

table part:

The diameter of the standard table top is 1600mm, and it is processed with 35mm thick 45# steel plate. The processing thickness is about 32mm, with a T-shaped groove. The standard table top has only one positioning hole, and the through hole type can also be customized according to customer requirements. The table size can be customized according to customer requirements.

Rack part:

The whole set of double-layer steel plate is welded and processed, the mechanical structure is reasonable, the whole machine is strong, simple and elegant.

Electrical control part:

The inverter is selected from Tianye, the warranty period is 12 months, and the wireless remote control is selected to facilitate user operation.

Auxiliary part:

It is recommended to use vertical machine clamps or clamps to fix the workpiece.

application

Manufacturing Technology

Product packaging

VIEW MORE

You may like

-

Pipe work piece rotating machine turntable 30kg mini welding positioner for sale

-

220V 30kg 100kg 300kg China Pipe Flip Positioner Welding Turntable Sales

-

Control tube welding positioner with foot switch 50kg per tube

-

10kg automatic welding positioner welding turntable for pipe rotation welding

-

Welding Positioner

-

China Wuxi YC Automatic Welding Positioner with Automatic Rotary Welding Table

-

Three-jaw shaft tube welding positioner

-

Small welding positioner/electric rotary table for MIG/50KG welding table with WP200 manual chuck/rotator wdbwj-0.5

-

rotary welding table 10 kg rotary welding positioner with 65 mm chuck and foot pedal

-

Welding turntable/rotary table/welding positioner can stop by itself Load capacity 300KG with 400mm welding chuck

Other Products

-

$1555.00 - $1755.00 / set

$1555.00 - $1755.00 / set -

$1550.00 - $1750.00 / set

$1550.00 - $1750.00 / set