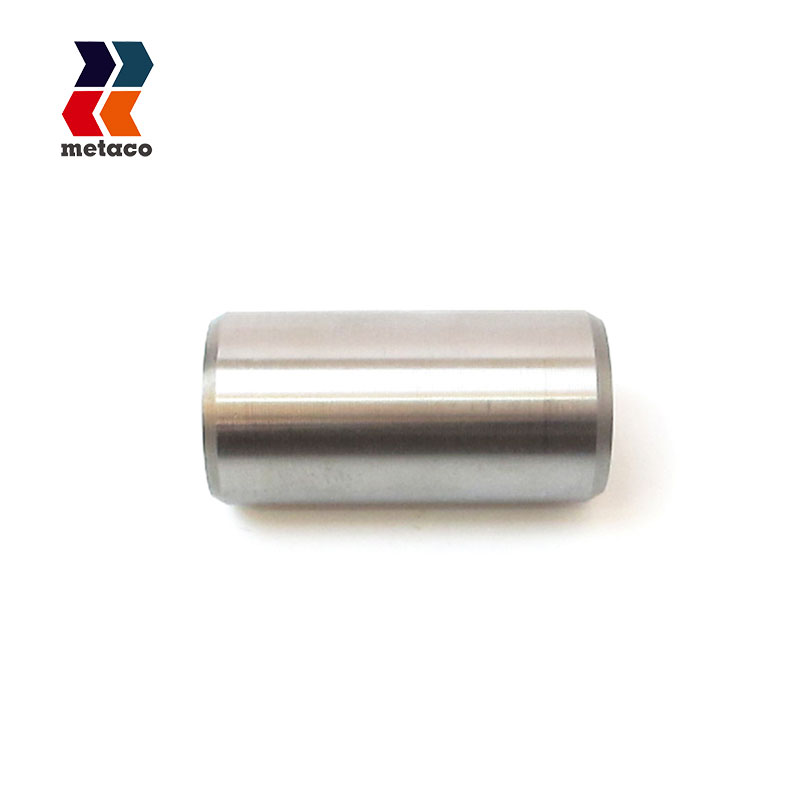

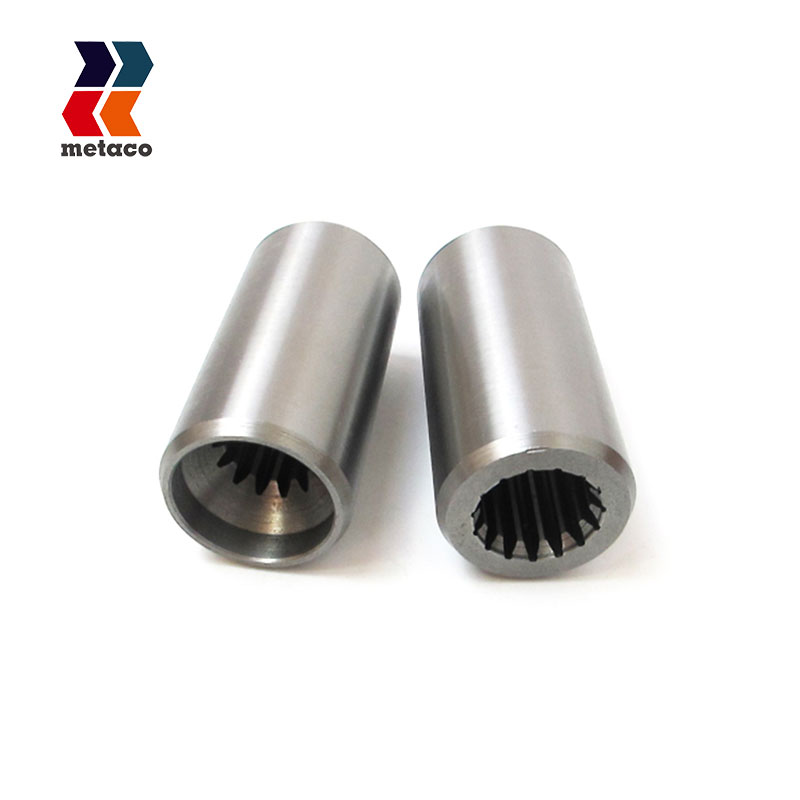

Automobile Steering System Axial Formed Alloy Steel Spline Coupling

-

Supplier: Yantai Metaco Electromechanical Equipment Co., Ltd. -

Region: Shandong, China -

Contact: Mr Lyman Wang -

Price: $3.00 / >=100 pieces -

Min. Order: 100 pieces

| application: | Automobile chassis system | structure: | gear |

| Supply capacity: | 1000 pieces per week | port: | Qingdao; Yantai; Tianjin. |

| Processing: | accept | Package: | Neutral packing |

| brand: | Metaco | Flexible or Rigid: | boring |

| process: | Normalization | product name: | Automobile Steering System Axial Formed Alloy Steel Spline Coupling |

| Processing: | Rotary forging | Element: | axis |

| Key words: | Stainless steel spline coupling | Packaging Details: | Plastic bags, cartons, plywood boxes, or according to customer requirements. |

| Standard or non-standard: | Non-standard | model: | custom made |

| color: | Nature | Material: | Steel, copper, stainless steel, carbon steel, cold rolled steel, etc. |

| payment terms: | L/C, T/T, Western Union | Origin: | Shandong China |

| Serve | |

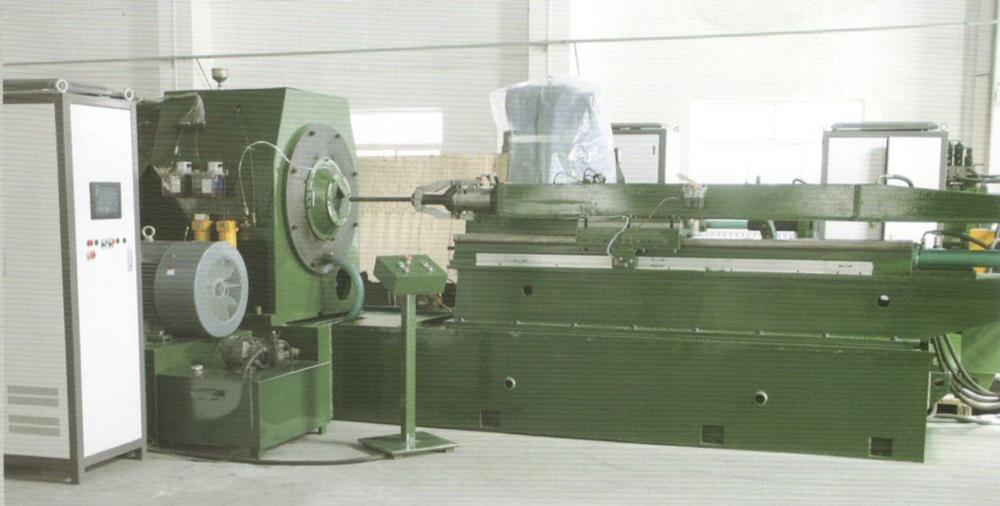

Professional customized rotary forging equipment

Provide rotary forging process

Forging die design and manufacture

Rotary special parts

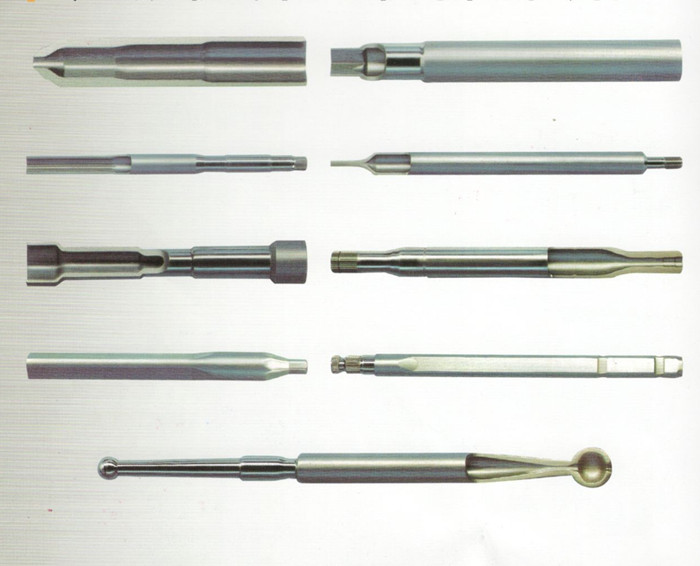

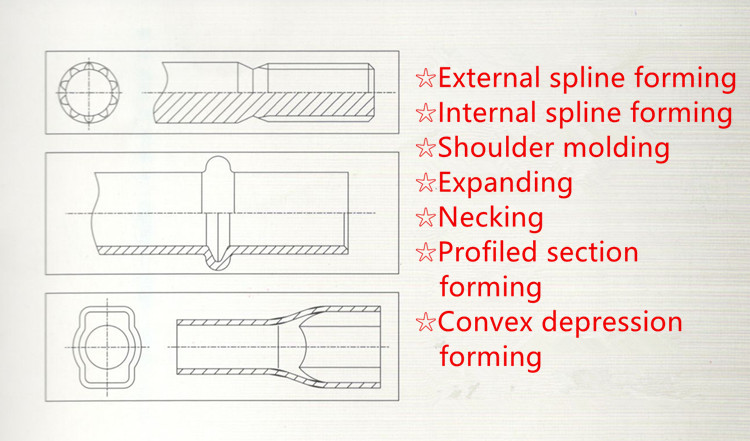

The rotary forging process has its unique and significant advantages.

The processed hollow steering columns, hollow transmission shafts and tie rods are widely used in automobiles, aircrafts and other fields.

vibration axial forming

Vibratory axial forming has the advantages of force reduction, stress release, sufficient lubrication, high precision, high efficiency, and cold work hardening.

External spline forming, internal spline forming, shoulder forming,

Diameter expansion, neck reduction, profile forming,

Concave-convex molding, etc.

factory

workshop

The Metaco product range includes bright steel, shafts, piston rods, track components, automotive clamps, dies and other machined metal components.

Capabilities include metal cutting, turning, milling, planing, grinding, EDM, CNC and complex machining. Metaco also benefits from local resources including casting, forging, heat treatments such as nitriding, carburizing and heat treatment, PVD coating and more.

Packaging details: packing, solid bicycle saddle, wooden box, etc.

Delivery Details: 15-30 days.

New Zealand customers

Our customers have established long-term and friendly relationships with us.

Iranian customers

Our customers are all over Japan, South Korea, New Zealand, Pakistan and Iran, etc.

Q: Do you make customized/customized products according to our design drawings?

A: Yes, we can not only manufacture your products according to your drawings, but also assist you in designing new products.

Because we use 3D SolidWorks software, this means we can develop products from your concept.

Q: How long is your delivery time?

A: Generally, we can produce in less than 20 days. It may take longer if your product is more complex.

Q: How thick can your CNC machining machine process?

A: Our laser cutting machine is 4000w, and the size of the processing range is 3050x1525.

Generally, carbon steel is less than 16mm, and stainless steel is less than 10mm.

Q: With Trade Assurance, you will enjoy:

A: 1. On-time delivery guarantee

2. Product quality assurance.

3. Payment Protection for Your Covered Amount

4. For your convenience, we provide various payment methods.

-

Flexible Coupling VS110 Rexnord-Falk VIVA Elastomer Coupling

-

L035 L050 L070 L095 rubber coupling with jaws

-

Jaws Love Joy

-

Industrial High Quality Star Flexible Shaft Coupling Claw Coupling

-

SWC-BH type high-speed universal coupling universal drive shaft

-

SLGR MINUC065 SWC-I100DH-304+30 power output cardan shaft finishing engineering machinery shaft

-

Flexible gr rotex 38 KTR GS GR coupling rubber spider pad

-

Factory direct powder metallurgy sintered steel spline coupling

-

Drum Gear Shaft Coupling For High Speed Turbine Gear Coupling China Factory

-

China Supplier High Pressure Coaxial Drive Shaft Chain Coupling Steel Sprocket Flexible Roller Chain Coupling