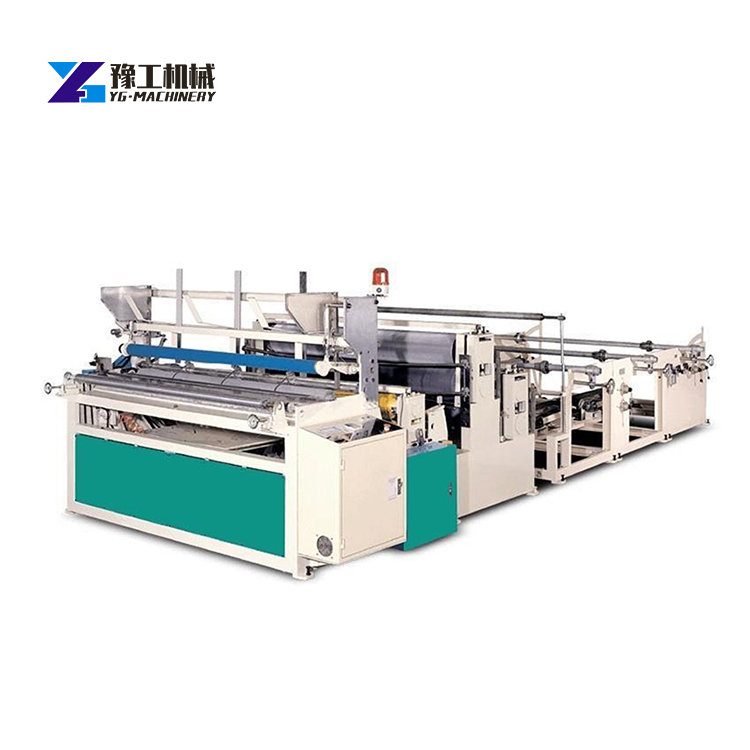

Fully automatic roll toilet paper and kitchen paper production line

-

Supplier: Henan Yugong Machinery Co., Ltd. -

Region: Henan, China -

Contact: Mr Karl Chan -

Price: $60000.00 / 1 - 9 sets

$50000.00 / >=10 sets -

Min. Order: 1 set

Product details

| Warranty: | 1 year | Trim Width: | 1880-3800mm |

| Origin: | Guangdong, China | Automatic level: | automatic |

| brand: | YG/Yugong | Dimensions (L*W*H): | 6500*3100*2600 mm |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | Core components: | Programmable Controllers |

| Packaging Details: | wooden box or | Machine capacity: | 150 rolls/min |

| weight: | 3800 kg | Raw paper width: | 2100mm |

| port: | Qingdao/Shanghai/Tianjin | Supply capacity: | 30 sets per month |

| type: | Paper production line | Health status: | new |

| Key machines: | paper cutter, toilet paper machine | Product Category: | napkins, facial tissues |

| Voltage: | 220 V/380 V or other requirements | Speed of work: | 150-1000m/min |

Product Description

Roll toilet paper and kitchen paper production line

Roll paper production line includes: paper machine, rewinding and cutting machine, paper packaging machine.

1. paper machine IIt is the general term for the complete set of equipment that makes pulp into paper web. It includes headbox, wire section, press section, dryer section, calender, paper roll and drive section. Auxiliary systems such as vacuum, lubrication, heat recovery, etc.

Process flow: forming department, pressing department, drying department, surface treatment department, transmission system, white water system, auxiliary system.

Raw materials for papermaking: including plant fibers and non-plant fibers (inorganic fibers, chemical fibers, metal fibers).

Process flow: forming department, pressing department, drying department, surface treatment department, transmission system, white water system, auxiliary system.

Raw materials for papermaking: including plant fibers and non-plant fibers (inorganic fibers, chemical fibers, metal fibers).

+

trim width | 1880mm--3800mm | ||||||

Weight range | 13--45 grams | ||||||

design speed | 180--1200m/min | ||||||

Speed of work | 150--1000m/min | ||||||

production capacity | 5--60 tons/day | ||||||

+

2. Rewinder It is a special equipment for paper, mica tape and film. Its purpose is to rewind the paper rolls produced by the paper machine (called base paper rolls) sequentially, and then enter the finished paper mill after rewinding.

The rewinding process mainly completes three tasks: first, cut off the rough edges of the base paper; second, cut the entire base paper into widths that meet user specifications; third, control the roll diameter of the finished paper roll to meet the factory specifications.

+

3.Web Slitting Machine: Suitable for slitting cored and coreless webs.

+

4. Web wrapping machine:

PThe paper roll packaging machine is suitable for the packaging of regular materials such as roll paper. The whole machine is composed of automatic feeding part, packaging machine main part, ironing part and control part.

+

VIEW MORE

You may like

-

2-layer corrugated cardboard production line box making machine single-sided machine production line

-

Economical writing paper making machine with handle paper bag making machine multifunctional paper making machine

-

Fully automatic origami production line with clapboard

-

Second-hand 5-layer corrugated cardboard production line

-

MJSGL-1 single-sided two-layer corrugated cardboard production line

-

High Quality Small Business Ideas Napkin Packaging Machine Easy To Operate Toilet Paper Production Line

-

The best paper tube production line

-

Coated Double Sided Cardboard Making Machine China Manufacturer Waste Recycling High Quality Grade A Four Wire 150-400 GSM Packaging White

-

RYHM Royal Packaging Fully Automatic A4 Paper Production Line

-

High-speed hydraulic paper plate machine production line

Other Products

-

$2300.00 - $2600.00 / bag

$2300.00 - $2600.00 / bag -

$1000.00 - $2000.00 / set

$1000.00 - $2000.00 / set -

$5600.00 / set

$5600.00 / set -

$1500.00 - $5000.00 / set

$1500.00 - $5000.00 / set -

$880.00 - $1750.00 / set

$880.00 - $1750.00 / set -

$10000.00 - $25000.00 / set

$10000.00 - $25000.00 / set

Related Search

gypsum board paper production line

cup paper production line suppliers

custom complete paper production line

toilet paper making machine

toilet paper rewinding machine

press roll for paper machine

abrasive cloth roll sand paper

rolling ph paper

coconut oil machine fully automatic

fulli automat nitrogen generat