Automatic Duct Machine Hvac Duct Forming Machine Automatic Duct Production Line WINYING 5

-

Supplier: Anhui Wenying Machinery Technology Co., Ltd. -

Region: Anhui, China -

Contact: Mr ping rui -

Price: $10000.00 /set -

Min. Order: 1 set

| strength: | 30 | brand: | Yingying |

| Packaging Details: | Standard plastic airworthy packaging | Sheet thickness (mm): | 0.5-1.2 |

| Origin: | Anhui, China | Production capacity: | 15 |

| Dimensions (L*W*H): | 23000*3300*1500 | port: | Shanghai |

| Core component warranty: | 2 years | Core components: | PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump |

| Health status: | special offer | Mechanical test report: | if |

| Warranty: | 1 year | Marketing Type: | New Products 2021 |

| Showroom location: | not any | weight: | 12000 kg |

| Video shipment inspection: | if | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

| Main selling points: | easy to operate | Applicable industries: | Building material stores, energy and mining, construction works |

| Supply capacity: | 200 sets per year |

The super five-line air duct production consists of a feeding rack, leveling ribs, hydraulic punching point punching, hydraulic shearing machine, fast biting machine, manipulator grasping and positioning feeding platform, double-machine joint common plate flanging machine, double linkage biting Forming machine, servo feeding platform, TDF hydraulic folding machine. The electrical control part adopts full computer control, bending servo feeding, and accurate positioning.

The feeding speed can reach 6m/min, and the length error is ±0.5mm. This line can process two kinds of air ducts, TDF ordinary plate flange and angle iron flange, and the exchange is simple and fast.

Features: Linear processing, high production efficiency, at least one operator is required. The daily processing capacity is 2,000 square meters. You only need to input the size of the air duct, and the production line automatically completes uncoiling, leveling, reinforcement, impact angle, shearing, joint occlusal, ordinary plate flange/angle iron flange forming, and folding.

Main configuration

Electrical configuration system PLC: German Siemens.

Servo motor Taiwan Dongyuan contactor

Circuit breaker: Chint oil pressure valve

Reversing valve: Beijing Huade

Airless Cylinder: Parker

Linear guide rail: Taiwan Wantong

Inverter: Taiwan

| Model | Sheet Thickness (MM) | Maximum Width (MM) | Maximum working speed (MM) | cutting weight (T) | Dimensions (MM) | Power(KW) | Weight (T) |

| ADL-V-1300 | 0.5-1.2 | 1300 | 15 | 7 | 23000*3300*1500 | 30 | 12 |

| ADL-V-1500 | 0.5-1.2 | 1500 | 15 | 7 | 23000*3600*1500 | 30 | 13 |

Why choose us

Company strength

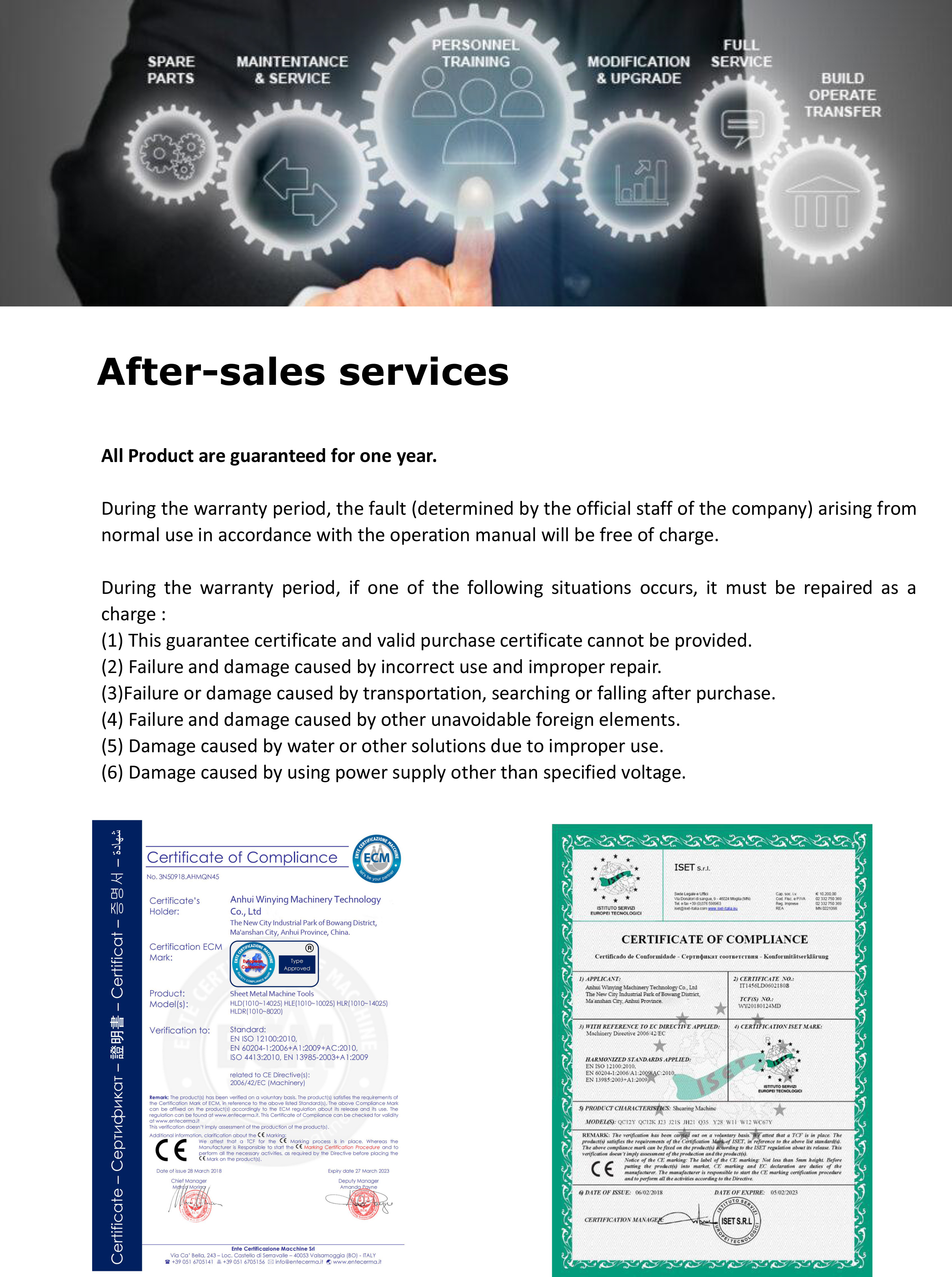

Anhui Yingying Machinery Technology Co., Ltd. is a high-tech enterprise with laser technology as the core, engaged in laser research, sheet metal machine tool production, laser application and sheet metal automation complete equipment research and development, production and sales. The whole series of products have passed the European CE safety certification, and obtained a number of national patents, and China's famous AAA standard good enterprise certification.

Why choose us

We are the leader in the transformation of the industry from automated products to intelligent products. The company has carried out a number of industry-university-research cooperation with many colleges and universities, and has gathered a group of experienced and skilled professionals.

Innovation, providing targeted laser application solutions for domestic and foreign users. There are more than 40 professional production technicians of various types, and a mature domestic integrated R&D team.

With an annual production capacity of 1000 machines, built in our 20,000 square meter production facility.

Customer Support

The products are exported to more than 100 countries and regions at home and abroad, and the company enjoys a high reputation abroad. With a complete laser CNC equipment production base, experienced technicians and a mature sales team, we can tailor a complete set of laser processing solutions, laser equipment and services for domestic and foreign customers.

Serve

Our commitment is to present the best quality to customers, which is why Yingying has been affirmed by customers and will continue to cooperate with them, no matter you are a dealer working with us or an end user of our products. With the support of our professional technicians and the quality of our machines, our customers will be able to get the most complete and timely solutions from our customer service team.

FAQ

Q1: After I bought the machine, if I don't know some functions, what will you do?

A1: We will show you how to use the machine perfectly. Provide technical support and videos.

Q2: Can you tell me how to install the machine?

A2: Of course, we will attach the production specification with the machine, we can provide the video to you online, and our engineer can repair the machine overseas.

Q3: How about your after-sales service?

A3: Our experienced engineers are waiting to serve you. Top-notch terms of service enable us to survive the fierce competition.

Q4: What's the policy of warranty and broken parts?

A4: The equipment warranty period is two years, and damaged parts and spare parts caused by quality reasons during the warranty period can be provided free of charge.

Q5: How about your price?

A5: Reply to me, I will give you my favorable price immediately!

Q6: What's your payment terms like?

A6: 30% deposit and balance paid within 3 days against the copy of B/L. Other payments are negotiable.

Q7: What is your package?

A7: Standard export packing, free plastic sea packing and standard wooden case.

Q8: Instruction Manual and DVD

A8: When the machine is shipped, the relevant operating instructions of the model will be shipped together with the machine. And there is a teaching video in the instruction manual.

-

RONGWIN channel production line folding machine for sale

-

BYFO angle iron flanges for the production of stainless steel channel flanges

-

Genuine Manufacturer Seam Lock Closure Machine Pittsburgh Seam Sealer

-

HVAC Manual C-type splint bending machine 750mm/C-type splint bending machine

-

Pittsburgh Seaming Cabinets

-

cheap price pipe tdf flange forming machine HVAC flange manufacturer

-

Multifunctional Pittsburgh locker making molding machine spot

-

channel machinery SBKJ

-

Channel forming machine hvac plasma cutting machine

-

J-1.5*80 90 degree pedal air duct cutting angle slotting machine