small biscuit machine

-

Supplier: Jinan Delon Machinery & Equipment Co., Ltd -

Region: Shandong, China -

Contact: Mr Jack Su -

Price: $12000.00 / 1 - 1 sets

$11000.00 / >=2 sets -

Min. Order: 1 set

| Packaging Details: | wooden box | Marketing Type: | New Products 2020 |

| brand: | Delong | Dimensions (L*W*H): | 17m*0.6m*1.34m |

| Output product name: | biscuit | Application fields: | Snack food factory, biscuit making |

| Warranty: | 1 year | Mechanical function: | biscuit making |

| Function: | make cookies | Origin: | Shandong China |

| Voltage: | 220V/380V/415V/440V 50HZ/60H | Core component warranty: | 1 year |

| port: | Qingdao Port | Mechanical test report: | if |

| type: | fully automatic | usage: | biscuit making |

| application: | biscuit processing | strength: | 29kw/118KW |

| Core components: | Engines, bearings, gearboxes, motors, pressure vessels | Package preview: | |

| product name: | biscuit machine | payment terms: | L/C, Western Union, T/T, MoneyGram |

| raw material: | Wheat flour and bean cakes, milk, corn, fruit, wheat, nuts, soybeans, flour, vegetables, water | Showroom location: | not any |

| Main selling points: | automatic | weight: | 3500 kg |

| Health status: | new, new | Video shipment inspection: | if |

| Electronic equipment: | ABB (or customized | Material: | Stainless steel |

| Stainless steel: | SS304/202/316 | Applicable industries: | Food and beverage factory, food and beverage store, biscuit or cookie factory |

| Supply capacity: | 20 sets of biscuits per quarter make the machine smaller |

small biscuit machine

Biscuits can be divided into soft biscuits and hard biscuits, depending on the formula, process and molding method. Soft biscuits are shaped by a rolling machine. The hard biscuits need to pass through three pressing rollers, and then they are rolled into shape through the mold, and the scraps are placed on the back of the feeding bucket.

This small soft and hard biscuit all-in-one machine can meet your needs for making soft and hard biscuits at the same time.

Different roll widths meet different production capacities. So please provide as much detailed information as possible so that we can provide more professional advice.

1. The type of biscuits you want to produce. You can provide a sample image.

2. The production capacity you need. Different models meet different production capacities.

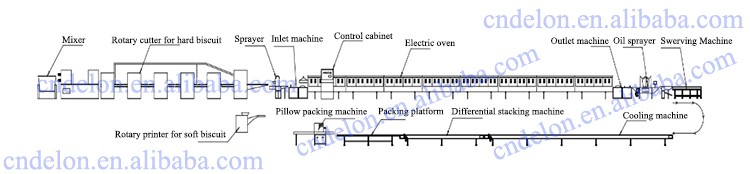

small biscuit machinePowder mixing machine, peel folding machine, candy filling machine, forming machine, egg brushing and granulating machine, tunnel furnace, steering machine, fuel injection machine, cooling transmission, sugar/salt pouring machine, etc.

The small biscuit machine is a device with novel design, compact structure and high degree of automation, which is digested and absorbed by the company from Japan. It is fully automatic from feeding rolling, forming, waste recycling, drying, oil spraying and cooling at one time. Our company, Provide users with hundreds of molds and dozens of process formulas. By changing the molds and process formulas, various high-end cookies that are popular in the market can be produced, such as butter cookies, biscuits, pancakes, soda crackers, multidimensional animal biscuits, biscuits, vegetables, biscuits, etc.

The layout of the small biscuit machine

Pparameterssmall biscuit machine

Sample of small biscuit machine

The main features of the small biscuit machine

1> Help customers design the plant, provide professional advice, and provide free plant layout engineering drawings.

2> Check the machine before leaving the factory.

3> Overseas installation and commissioning of equipment.

4> Train front-line operators.

5> Provide basic formula

How the cookies are made in the factory

The production of biscuits in the factory includes steps such as mixing, forming, baking and cooling. These are the four main stages of biscuit production.

The first step is to feed the ingredients like flour, sugar, fat into the mixer to prepare the dough. The mixing phase is usually done multiple times at different speeds, but flour properties also play a role.

The next step requires lamination and transfer of the dough to measuring rolls. It is at this stage that the biscuits acquire their shape through cutting or molding.

The third stage is baking the biscuits in the oven, where radiation, convection and conduction give the biscuits the correct color and volume. The cookies are fed into the oven on a wire mesh belt.

In the cooling stage, the biscuits are placed on a 300 to 400-foot cooling conveyor to cool at room temperature. According to Delon, natural cooling is preferable to forced cooling in order to preserve the textural quality of the biscuits.

The biscuits are then sent to a packaging machine where they are packed into block packs, pouch packs or home packs for shipment to retailers. Industry and regulatory standards require quality control checks at every step of production.

mixer

Function:The dough mixer is a mixing machine that kneads flour and water into dough or other materials and is used independently of other machines.

strength:0.75kw

aspect:1280*1280*620mm

Hard Biscuit Rotary Cutter

After the stirred flour powder is put into the machine, it is formed into raw biscuits, various medium and high-grade biscuits and thin biscuits at one time through the three-section rolling cutting mold.

Soft biscuit rotary printer.

Put the mixed flour into the machine, knead it into biscuit embryos, and put it into the oven to make various medium and high-grade biscuits.

oven

Function: After the immature biscuits enter the infrared baking oven conveyed by the belt, they are processed by a low-temperature and long-term baking system to make the biscuits mature.

aspect: 2*0.51*0.9m (one)

strength: 20.5 kW

sandwich maker. Elective

This machine is used to make sandwich biscuits.

Fuel injector

The baked undried biscuits immediately enter the oil injection machine, which is necessary for the production of high-grade biscuits, and can better improve the grade and color of biscuits.

Cooler

This machine is used to cool the biscuits before they are conveyed to the packing machine, so as to ensure the quality of the packed biscuits and prolong the shelf life.

Packing Machine.

This model is suitable for biscuit packaging. The utility model has the advantages of novel structure, beautiful appearance, low noise, stable operation, low failure rate and convenient maintenance.

pre-sale service

A). The supplier shall test run the entire production line at the supplier's factory before shipment;

b). The supplier must run the machine for at least 1 hour for each product;

c). All raw materials for the trial run of the twin-screw extruder shall be arranged by the supplier at his own expense.

After-sales service

A). Free consulting services before, during and after sales;

b). Free project planning and design services;

C). Debug the equipment for free until everything is normal;

d). Long-distance transportation of management equipment for free;

e). Personal free training on equipment maintenance and operation;

F). Provide new production technology and formula for free;

G). Provide 1 year full warranty and lifetime maintenance service.

| size | |

| weight | |

Jinan Delong Machinery Equipment Co., Ltd. is a high-tech enterprise integrating science, industry and trade. We are committed to developing, manufacturing and selling twin/single screw extruders, snack production lines, breakfast cereal/cornflakes production lines, bean meat production lines, pasta/macaroni production lines, pet food production lines, etc. for more than 10 years.

Q: Are you a manufacturer?

Answer: Yes,we aremanufacturer, Welcome to visit our factory and inspect the machines.

Q: If we have a good idea, can you design a new mold for us?

A: Yes, we can design new molds for you according to your original market demands.

Q: If we provide the layout of our factory, can you help us design the whole line?

A: Yes, we can provide you with the machine layout of the factory after we get your factory details.

Q: What information should I provide if I want a quotation?

Answer: ┅What kind of machine do you choose, or provide me with the kind of food you will produce.

---Your production capacity requirements.

---Provide us your production details, then we will provide you with professional advice.

Q: Why choose us?

A: ---Professional technology, we have been engaged in food processing machinery manufacturing for many years, accumulated rich experience and enjoyed a high reputation.

┅Fast delivery and good service.

│All machines are strictly inspected before shipment.

---Alibaba evaluates suppliers.

---Provide the basic formula.

-

Automatic biscuit forming machine for small business biscuit gingerbread making forming machine price

-

Vertical biscuit and biscuit packaging machine biscuit and biscuit making machine

-

Donut Machine Breakfast Cake Bread Bread Light Food Donut Machine

-

R260 Biscuit Cookie Snacks Making Sweet Household Electric Cookie Machine

-

Small soft biscuit production line price/biscuit machine production line

-

KH-QQJ-400 mechanical cookie machine, commercial cookie machine

-

Small automatic walnut shortcake forming machine biscuit making machine biscuit machine price special price

-

Manufacturers Supply Nut Cookies Production Line Cookie Forming Machine Equipment

-

Commercial Biscuit Making Machine Industrial Biscuit Production Line Biscuit Forming Machine

-

Commercial Biscuit Machine Automatic Soft and Hard Biscuit Making Machinery Stainless Steel Hard Biscuit Production Line

Other Products

-

$20000.00 / set

$20000.00 / set