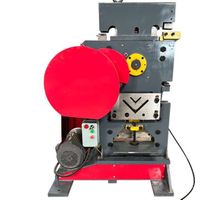

Q35y hydraulic sheet metal steelworker shear punching machine

-

Supplier: Nantong Weili CNC Machine Co., Ltd. -

Region: Jiangsu, China -

Contact: Ms Weiping Cui -

Price: $2000.00 / 1 - 1 sets

$1900.00 / >=2 sets -

Min. Order: 1 set

| After-sales service provided: | Online support, video technical support, free spare parts, on-site installation and commissioning training, on-site maintenance and repair services | port: | Shanghai |

| color: | Elective | Voltage: | 220V, 380V, 415V, 480V |

| Cutting material: | carbon steel, stainless steel | CNC or not: | CNC |

| Energy source: | hydraulic | Forging method: | die forging |

| brand: | Tongwei | Health status: | new |

| Supply capacity: | 30 sets per week | Slider movement: | double action |

| Certification: | International Organization for Standardization | Origin: | Jiangsu, China |

| payment terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram | Packaging Details: | wooden packaging |

| strength: | 5 | Warranty: | 3 years |

Q35Y series iron forging machine, hydraulic iron forging machine, sheet metal forging machine

Applications

Q35Y series hydraulic combined punching and shearing machine can cut and punch various materials such as plate, square bar, angle steel, round bar and channel steel.

Langdun industrial hydraulic blacksmiths are designed and manufactured to the highest quality standards in the industry.

This profitable machine will serve any tough fabrication shop for decades to come. His machines are usually in stock for fast delivery.

1. Punch

A full line of general purpose punches and dies is available. The unique pattern allows for high angle iron punches and large channel punches. The large viewing window on the swing-out design of the stripper provides easy access. Large two-piece measuring table, ruler and stop as standard accessories. Quick-change coupling nuts and sleeves for quick changes.

2. Shearing

Round and square rebar snips have multiple holes in various sizes. Adjustable hold-down for round/square bar, channel/beam cutting. Large and robust guards for maximum safety. Angle snips are capable of cutting top and bottom legs at 45°.

This enables the operator to produce perfectly welded picture frame corners. Diamond-shaped blades for high-quality cuts minimize material loss and deformation. Easily adjustable platen unit for precise sheet cutting.

Large 15" square arm with inlaid graduations. Special anti-twist blades for premium cuts. The lower blade has four usable edges. There are screws to allow clearance adjustment, no spacers required.

3. Grooving

Unique design allows cutting angle and flat steel. Electrically interlocked safety guards and three measuring stops for precise positioning. The grooving section of this hydraulic blacksmith is ideal for grooving sheet metal, angle iron, and more. The grooving station also has an oversized table with material stops.

This part of the machine can also be equipped with an optional V-groove.

4. Bend

Also bend the board to less than 500mm. All components of the machine are of the highest quality in terms of safety, functionality, performance and maintenance.

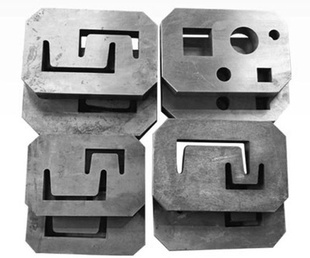

Parts List

1. A set of punching dies

2. A set of angle steel blades

3. A set of square and round blades

4. A set of shearing blades

5. A set of slotting blades

Model | Q35Y-12 | Q35Y-16 | Q35Y-20 | Q35Y-25 | Q35Y-30 |

Pressure (tons) | 40 | 66 | Post-90s | 120 | 165 |

Maximum Cutting Thickness(mm) | 12 | 16 | 20 | 25 | 30 |

Sheet strength (N/mm2) | ≤450 | ≤450 | ≤450 | ≤450 | ≤450 |

cutting angle | 7° | 7° | 8° | 8° | 8° |

One cut size(mm) | 12×220 6×360 | 16×250 8×400 | 20×330 10×480 | 25×330 16×600 | 30×355 6×360 |

Slider stroke(mm) | 80 | 80 | 80 | 80 | 80 |

Number of strokes (cpm) | 8 | 8 | 8 | 6 | 15 |

Throat depth (mm) | 250 | 300 | 355 | 400 | 600 |

Maximum punching thickness | 12 | 16 | 20 | 25 | 26 |

Punching diameter (mm) | 20 | 25 | 30 | 35 | 38 |

maximum. Punching diameter | 25 | 32 | 40 | 50 | 50 |

Punching thickness (mm) | 8 | 10 | 12 | 15 | 20 |

Main motor power (KW) | 3 | 4 | 5.5 | 7.5 | 11 |

Dimensions L×W×H(MM) | 1480×760×1620 | 1640×780×1770 | 1860×800×1900 | 2355×960×2090 | 2680×1040×2300 |

Machine weight(Kg) | 1230 | 1550 | 1920 | 4670 | 6450 |

-

New high productivity metal and steel manufacturing plant construction engineering steel processing small punching and shearing machine

-

Chinese manufacturer QA32-8B angle iron cutting machine

-

APEC hydraulic punching die - round hole / oval hole punching

-

Custom Top Punch Die

-

Hydraulic combined punching and shearing machine for sale ironworking machine combined punching and shearing machine

-

Professional hydraulic combined sheet metal working machine

-

APEC small hydraulic ironworking machine punching plate shear multi-function

-

Small hydraulic iron punching machine mechanical punching and shearing machine

-

Anhui Haili CNC sheet cutting machine adopts hydraulic cutting machine

-

Factory inventory Q35Y series steel ironwork hydraulic steel punching and shearing machine steel punching and shearing machine