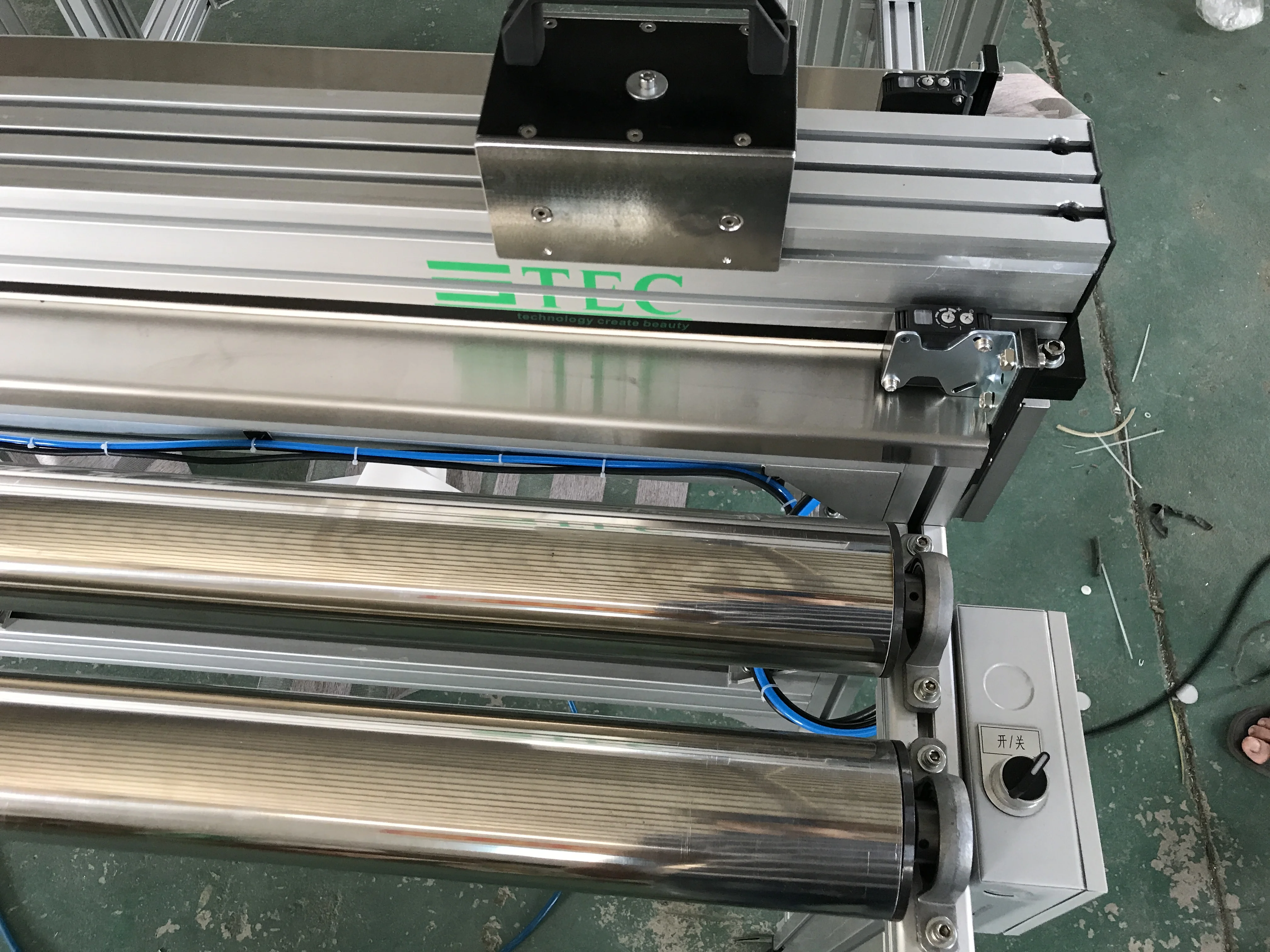

Multifunctional manual roller blind cutting table

-

Supplier: Guangzhou Stec Technology Co., Ltd. -

Region: Guangdong, China -

Contact: Mr Ryan Yun -

Price: $2500.00 /set -

Min. Order: 1 set

Product details

| Voltage: | No electricity | Package preview: | |

| payment terms: | L/C, T/T | Mechanical test report: | if |

| Applicable industries: | manufacturing plant | Weight (kg): | 400 |

| Core components: | pressure vessel | Marketing Type: | normal product |

| Packaging Details: | Steel frame and poly wood board | Origin: | Guangdong, China |

| Video shipment inspection: | if | Warranty: | 1 year |

| After-sales service provided: | Engineers available to service machinery overseas | Showroom location: | not any |

| Air: | need air compressor | Core component warranty: | 1 year |

| application: | fabric cutting | brand: | STEC |

Specification

Manual roller blind cutting table | ||

Voltage | 110/220V single phase (if equipped with safety sensor) | |

rated power | 30((if equipped with safety sensor) | |

working pressure | 5~6 | |

Maximum cutting width | 3000 standard | |

cutting system | manual blade cutting | |

safety sensor | Elective | |

aspect | L3400*W600*H1000 | |

Package Size | L3500*W700*H1200 | |

northwest | 300 | |

pack | Steel frame and poly wood | |

Product Description

Applications

The manual roller blind cutting machine is a simple, efficient and affordable machine for roller blind producers. It is widely used for cutting sunscreen fabrics, blackout fabrics, and one-layer/two-layer zebra pattern roller blinds.

main feature

1) Quick-push movable knife. Cutting can be started in both directions, saving time.

2) Double pneumatic cloth pressing rods ensure that the cloth is cut before it is fixed.

3) Can cut most single or double layer roller blind fabrics.

4) Aluminum alloy body, tungsten steel blade, long cutting life.

5) Safety sensors are installed on both sides of the pressure rod.

VIEW MORE

You may like

-

Second-hand high-speed multi-needle quilting machine HC 2500 looper stitch

-

Plush toy stuffing cotton fiber opening cushion sofa filling machine polyester fiber opening pillow filling making machine

-

The automatic cutting machine and the multi-needle quilting machine are equipped with a touch screen for easy operation.

-

Automatic plush stuffing portable stuffed toy stuffing machine

-

Production line of heat-bonded polyester-cotton rolls for quilt inner factory

-

1.5kw Polyester Fiber Toy Filling Machine Cotton Fiber Pillow Filling Machine / Teddy Bear Filling Machine

-

Automatic Quilt Duvet Filling Machine Goose Down Filling Machine For Pillows

-

Fully Automatic Pillow Filling Machine Polyester PP PET Fiber Opener Cushion Filling Machine HFC-700

-

Home Textile Manufacturing Equipment High Speed Fully Automatic Single Nozzle Cotton Filling Machine

-

DIY Plush Toy Stuffing Machine Teddy Bear Stuffing Machine

Other Products

-

$9999.00 / set

$9999.00 / set -

$10500.00 / set

$10500.00 / set