Electric Industrial air heater hot centrifugal air blower

-

Supplier: Foshan Luomei Electric Technik Co.,Ltd. -

Region: Guangdong, China -

Contact: Mr William Wei -

Price: $998.00 /piece -

Min. Order: 1 piece

Contact: whatsapp 008618823126158, luomeiele(at)163(dot)com

1. Technical Paramater

| Model: 0537 / 0737 / 1037 | |||

| Voltage | 220V 1ph (or 380V 3ph) | Max outlet temperature | 350℃ (reducing air volume) |

| Heater power | 5KW/7.5KW/10KW | Max inlet temperature | 200℃ |

| Fan power | 0.37KW | Max Airflow | 18m3/min |

| Heater material | 2080 Nickel chromium wire | Maximum pressure | 754Pa |

| Environment temperature | 0~40 ℃ | Dimension | below attached picture |

| Environment humidity | 60% R.H. | Net Weight | 35KG |

| Note: | If you want to change outlet diameter,please contact us,conventional 89mm | ||

| Model: 1075 / 1575 | |||

| Voltage | 380V three phase | Max outlet temperature | 350℃ (reducing air volume) |

| Heater power | 10KW/15KW | Max inlet temperature | 200℃ |

| Fan power | 0.75KW | Max Airflow | 36m3/min |

| Heater material | 2080 Nickel chromium wire | Maximum pressure | 937Pa |

| Environment temperature | 0~40 ℃ | Dimension | below attached picture |

| Environment humidity | 60% R.H. | Net Weight | 50KG |

| Note: | If you want to change outlet diameter,please contact us,conventional 89mm | ||

| Model: 2075 / 2575 / 3075 | |||

| Voltage | 380V three phase | Max outlet temperature | 350℃ (reducing air volume) |

| Heater power | 20KW/25KW/30KW/ | Max inlet temperature | 200℃ |

| Fan power | 0.75KW | Max Airflow | 36m3/min |

| Heater material | 2080 Nickel chromium wire | Maximum pressure | 937Pa |

| Environment temperature | 0~40 ℃ | Dimension | below attached picture |

| Environment humidity | 60% R.H. | Net Weight | 50KG |

| Note: | If you want to change outlet diameter,please contact us,conventional 89mm | ||

2. Product Introduce

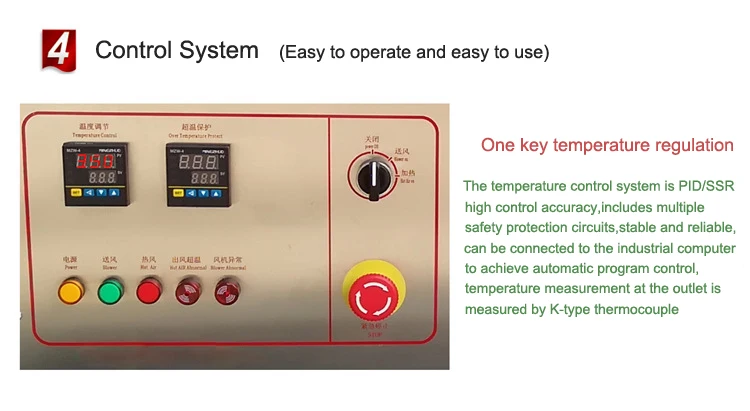

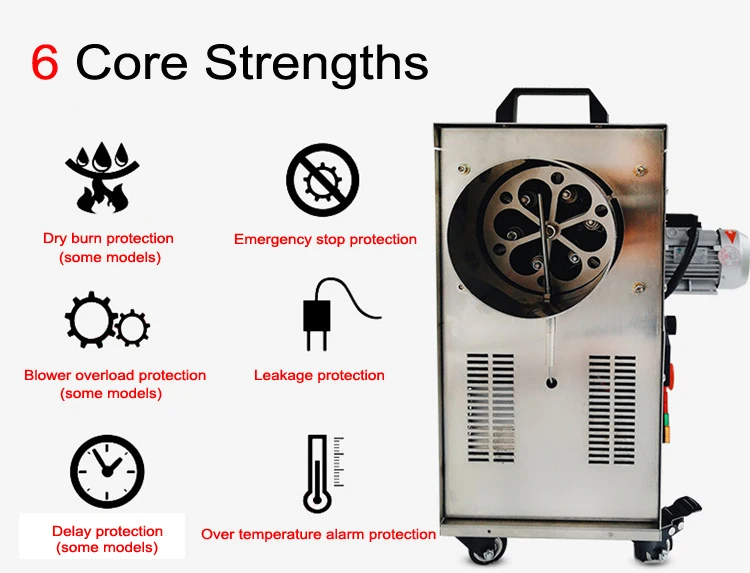

Hot air blower are generally composed of four parts: a heater, a fan, a temperature control system, and a cabinet.

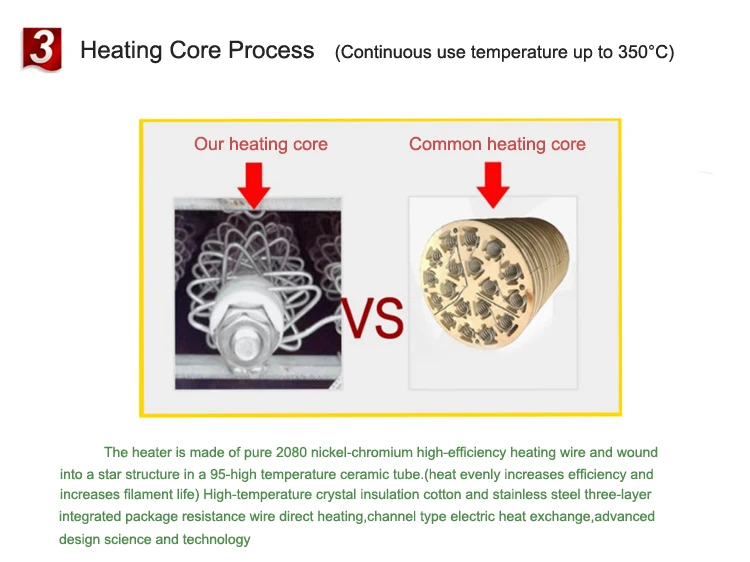

The heater part is made of pure 2080 nickel-chromium high-efficiency heating wire, high-quality high-temperature stainless steel casing, lightweight crystal insulation fiber blanket, 95 porcelain wiring board and other components. It has the characteristics of fast heating, small thermal inertia, precise temperature control and long service life. (Our heater core components use imported pure 2080 nickel-chromium alloy materials, some industrial enterprises have selected iron-chromium-aluminum heating materials, nickel-chromium materials, reclaimed silk, or inferior nickel-chromium wire to impersonate 2080 pure nickel-chromium wire, thereby reducing production. Cost. In application, generally used in three months or six months, the durability, stability, heat generation, accuracy and other aspects of the two products will have essential differences, which may lead to the loss of maintenance value of the product. Causes a production safety incident.)

The fan part is uniquely designed with low noise, can recycle hot air, and is energy efficient. Different wind pressure fans can be configured according to the actual needs of the user, which is flexible and practical. The fan air volume can be adjusted according to production needs.

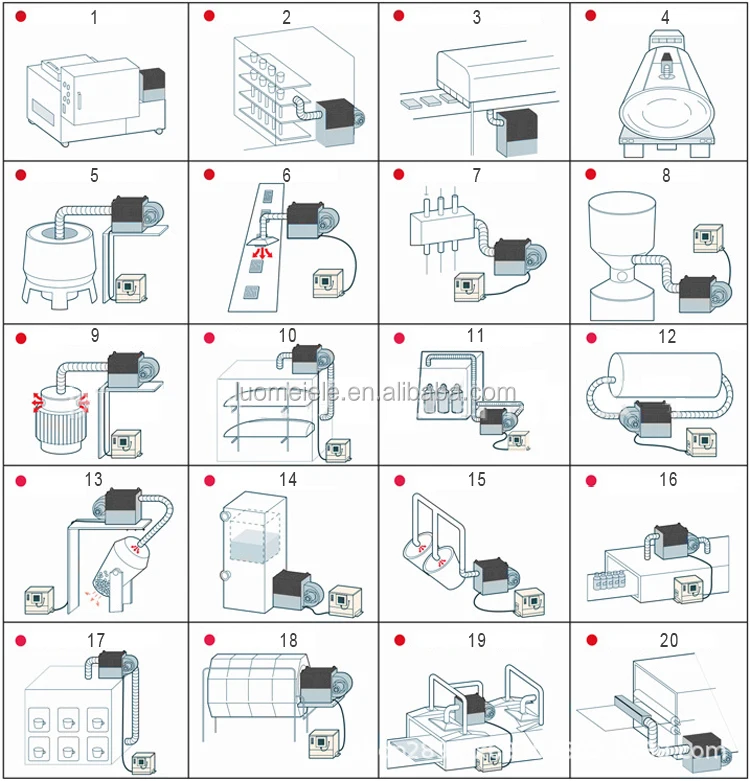

The hot air blower is suitable for heating and drying of the plant, heat source equipment in the drying room and heating in a small air flow area. Various industrial plants, workshops, steelmaking, coal mine heating and heating, preheating heating and drying of various construction sites, drying of pipeline anti-corrosion inner walls, speeding up the drying of paints, heating and warming in winter construction sites, preheating of machines Warm up. Chemicals, plastics and other products are dry, food is dried after cleaning, and heat shrinkable packaging has examples of use.

Applications

Applications

1. Assembly to cleaning equipment

2. Drying and heat sterilization of glass containers

3. Defrost before freezing food labeling

4. The inner wall of the tank and gas tank is dry

5. Drying of the centrifuge

6. Heating and drying of electronic components

7. Drying after cleaning such as copper wire

8. Drying in the hopper

9. Drying of the transformer box before painting

10.FRP resin drying

11. Heat drying of gas cylinders

12. Internal drying heating of vinyl resin

13. Copper ball heating

14. Drying of the sorbent

15. Drying of food

16. Shrinking and packaging drying in the tunnel furnace

17. Solidification and drying of plasticizer

18. Drying of small objects

19. Transformer dipped in insulating paint and dried

20. Drying after carton printing

-

ATO A8101 powerful power tool dual speed variable speed cordless drill 21V GS back paxk cordless hair dryer

-

WHAMX EB9500 85CC 2-stroke Gasoline Inflatable Backpack

-

Ring Blower / Side Channel Blower / Regenerative Vacuum Pump

-

Mellif Leaf Flower Cordless for DEWALT 18V 20V 60V WITH BATTERY POWER

-

High Quality Industrial Portable Electric Blower Factory Garden Machine Factory Tool Powerful Cleaning Blower

-

Custom Cheap Multicolor Lithium Battery Portable Blower Fan Cordless Leaf Blower Electric Blower

-

42.7cc Gasoline Backpacking Garden Leaf Blower

-

EB9500 Backpack Leaf Blower, Factory Snow Blower

-

1000W Computer Car Dust Leaf Grass Garden Yard Handheld Electric Blower

-

Power Leaf Blower Petrol Backpack Snow Plow For Road Cleaning

Other Products

-

$599.00 / piece

$599.00 / piece -

$20.00 / piece

$20.00 / piece -

$80.00 / piece

$80.00 / piece -

$80.00 / piece

$80.00 / piece -

$10.00 - $100.00 / piece

$10.00 - $100.00 / piece