1.4/1.6 17INCH motorcycle wheels for DY100 rim set motorcycle rims

-

Supplier: Taizhou Luqiao District Jindun Machinery Co., Ltd. -

Region: Zhejiang, China -

Contact: Ms Helen Chen -

Price: $23.00 / 100 - 299 sets

$18.00 / 300 - 999 sets

$14.60 / >=1000 sets -

Min. Order: 100 sets

Product details

| Braking method: | front drum back drum | Package: | carton |

| diameter: | 17 inches | Product packaging: | Carton - 2 pcs/box |

| port: | Ningbo Port | delivery time: | 10 days |

| Year: | 2006-2008 | Model: | City |

| model: | JD-O0922 | payment terms: | L/C, Western Union, T/T |

| brand: | Golden Shield | Packaging Details: | Carton or support customized |

| Finnish: | CNC machinery | Origin: | zhejiang |

| Car equipment: | Honda (GAC) | Material: | die cast aluminum |

| Package preview: | MOQ: | 100 sets | |

| color: | white/red/blue and customized | product quality: | Aftermarket Premium Brands |

| Supply capacity: | 300000 pieces per month |

front wheel | rear wheel | ||

Specification | 1.4X17 inch | 1.6X17 inch | |

brake method | drum | drum | |

color | silver/red/blue etc. | Black | |

Package | 2pcs/box | ||

Allow OEM or ODM

We are making wheels, we are the people who make wheels! ------Gold Shield

We want to be your wheel factory, making the wheels you want and creating your own unique wheels.

>>>>>>>>Click to communicate<<<<<<

Please note:Sample orders are usually shipped by courier, while bulk purchases are mainly shipped by sea. We will charge the sample and shipping cost, once you make bulk order, we will refund all the cost of the sample to you. Thank you for your understanding. If you need a special shipping method, you can also contact me.

about Us

Jindun has been a supplier of cast aluminum alloy wheels since 1993 and has many years of design and manufacturing experience in this industry. Our cast aluminum alloy wheels are integrally cast, which has higher strength and lower cost than traditional spoked wheels. We offer competitive prices and fast delivery.

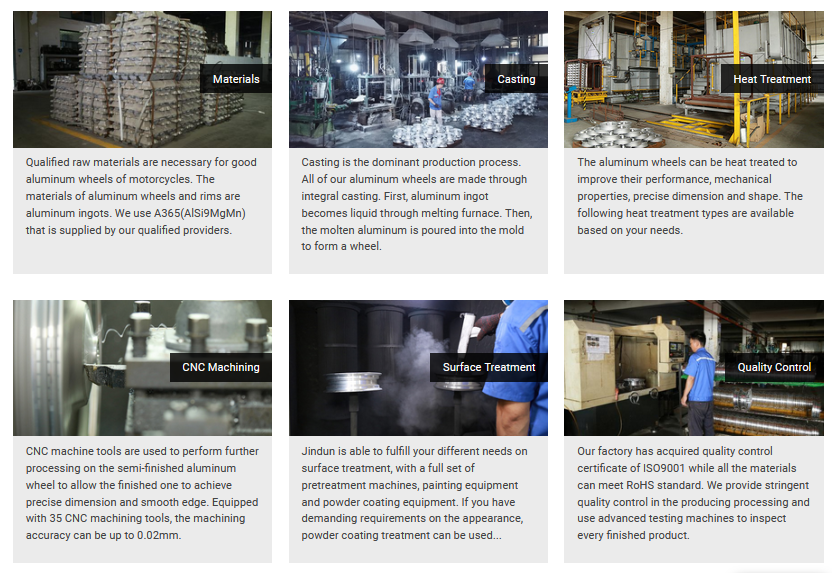

Today, we can produce up to 1,500,000 cast alloy wheels per year. We have a professional manufacturing plant that can automatically complete all processes, including material selection, casting, CNC machining, heat treatment, surface treatment and testing, and have strict quality control and production plans. If you have any questions about custom alloy wheels, please contact us.

The process of making the wheel

A qualified aluminum alloy wheel needs careful planning and production process, including material selection, casting, heat treatment, surface treatment, etc. Each step is carried out by high-quality equipment, including melting furnaces, die-casting machines, CNC machine tools, heat treatment furnaces, pretreatment machines, coating equipment, etc. This allows us to create alloy wheels that our customers love. Each aluminum wheel is strictly tested before delivery. These are our test machines.

Q1: Can you send me a sample?Answer: Yes! We can send you samples to check our quality. You need to pay the sample fee, but we will refund you once you place bulk order from us.Q2: Do you have design ability?A: We are a manufacturer and can provide customized service, just send drawings or samples, new ones will be made.Q3: Can I add my logo on the motorcycle parts?A: Yes, we can work with OEM and ODM. But you should send us the trademark authorization letter.Q4: Why should you buy from us not from other suppliers?A: 1. Flexible management system, able to communicate directly with the boss to improve project progress. 2. Competitive price. We are a factory and can increase or decrease the cost reasonably for you. 3. Sound departments and professional teams. We have independent departments from design to quality inspection. The heads of various departments have been engaged in the wheel hub industry for 15 years and can effectively provide guarantee for the products. 4. The production process is transparent, and the production status of the product is recorded for you in real time.

VIEW MORE

You may like

-

CNC 1.85/2.15*14" MIO VARIO BEAT CLICK NVX MIO AEROX N MAX VARIO 160 motorcycle flange aluminum alloy disc brake rim

-

WM type wheel rims for sale

-

Motorcycle Wheels Lc135 17 Inch 511 Aluminum Alloy Motorcycle Wheels Disc/Dull

-

Refacciones motorcycle spare parts motorcycle rims front and rear aluminum rims 16/18 inch for Suzuki/Honda GN

-

12 Inch Aluminum Alloy Scooter Motorcycle Wheels

-

5 Axis CNC Machining Customized 7075 Motorcycle Alloy Wheel Rims According to Customer Requirements

-

Motorcycle rim mount with customizable solid color wheels

-

17 18 19 21 inch custom aluminum alloy

-

dirt bike rims pit bike rims dirt bike and tires

-

For SNIPER 150 Motorcycle Front/Rear Retrofit Rim With Disc Brake Aluminum Wheel For 17 Inch

Other Products

-

$40.00 - $59.00 / piece

$40.00 - $59.00 / piece