MIG MAG gas shielded pulse welder for robotic arm

-

Supplier: Shanghai Fengling Welds Co., Ltd. -

Region: Shanghai, China -

Contact: Ms Alisa Wang -

Price: $300.00 / 50 - 99 pieces

$250.00 / >=100 pieces -

Min. Order: 50 pieces

Product details

| Certification: | International Organization for Standardization | Warranty: | 1 year |

| Customization support: | Processing | Dimensions (LxWxH): | 660*320*560 |

| pay: | T/T, L/C | Maximum Wire Diameter: | 5mm |

| payment terms: | L/C, Western Union, T/T | product name: | Tungsten inert gas shielded welding machine |

| port: | Shanghai, Tianjin | OEM: | accept |

| pack: | carton | Packaging Details: | 1 piece/carton |

| weight: | 55 kg | brand: | Pulse MIG-500RP |

| Origin: | China Shanghai | Supply capacity: | 200 sets per month |

| Serve: | 24 hours online/hotline |

Product Description

product name: | Robotic Pulse MIG Welding Machine | ||||||

aspect: | 660*320*560mm | ||||||

feature | Excellent weldability: 1. One-pulse-one-droplet control technology realizes spatter-free welding. 2. The enhanced double pulse function can realize the perfect seam seam and improve the welding quality of aluminum alloy welding. 3. The fully digital system realizes precise control of droplet transfer and continuous and stable welding quality. 4. The arc start and end arc parameters are adjustable, and the welding quality is high. 5. Up to 100 sets of user-defined parameters can be stored for easy adjustment. 6. All-digital high-precision wire feeding system, two drives and two slaves with encoders, all-digital control wire feeding system device, even if external factors such as power supply voltage and wire feeding resistance change, the welding machine can still Ensure the stability of wire feeding. 7. Suitable for welding carbon steel, stainless steel, aluminum and aluminum alloy, copper and copper alloy. Additional functions for welding robots 1. Equipped with the initial detection function, the initial detection of the weld can be completed without adding Robot hardware. 2. The digital interface is equipped with arc tracking function, which can cooperate with the robot to complete the welding seam track. 3. Open communication mode, the robot can control the parameters used by the welding machine. 4. International general standard Devicenet/CAN/CANopSen/485/EtherNetIP digital communication interface, realize Seamless integration with different brands of robots. 5. Integrated analog communication interface, plug and play. | ||||||

Product parameters

Input voltage | Three-phase 380V±10%, 50Hz |

Rated output | 500A/39V |

Applicable wire | Solid wire / Flux wire |

air shield | MIG/MAW |

Wire diameter | 0.8-1.6mm |

Duty Cycle (40°C) | 60%; 100%; |

Welding material @ pulse mode | Carbon steel, stainless steel, aluminum-magnesium alloy, pure aluminum and aluminum-silicon alloy, copper and copper alloy |

| Welding materials @constant pressure mode | CO2 carbon steel, argon-rich carbon steel |

degree of protection | IP23 |

torch cooling | air/water |

Welding current | 25-500A |

The output voltage | 17-39V |

power factor | ≧0.87 |

FrequencyHZ | 50/60 |

gas flow | 15-20L/min |

aspect | 660*320*560mm |

weight | 55 kg |

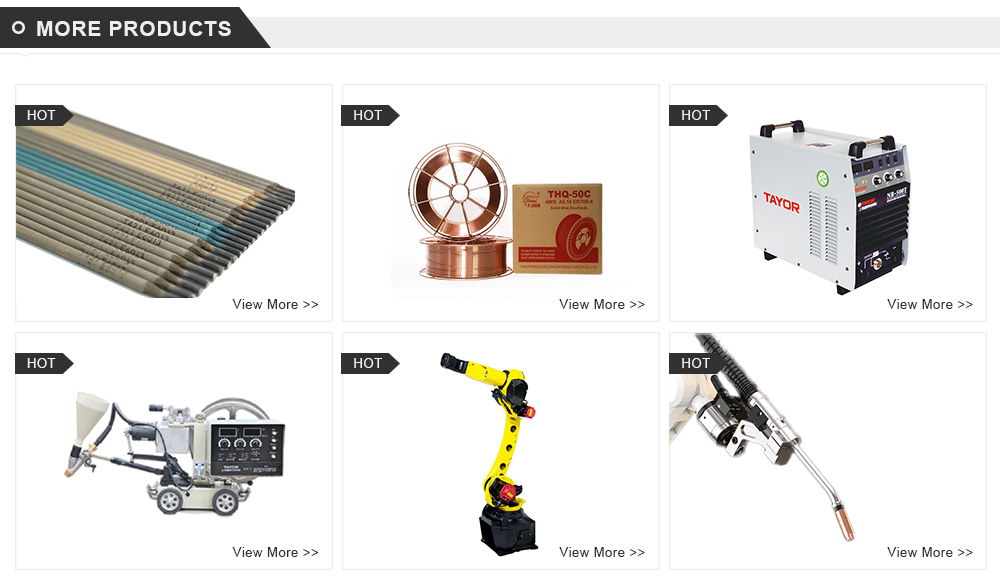

more products

Applications

VIEW MORE

You may like

-

The popular and versatile green TIG enclosed wire feeder

-

MIG/MAG Wire Feeder Control Box for Wire Feeder Components

-

Intelligent control MIG-130 airless flux cored wire MIG welding machine MIG MMA welding machine

-

Argon arc welding wire feeder

-

Powerful small electric IGBT argon arc welding machine TIG-200

-

kingnow cheap Light outdoor user stud mig 120 ECO inverter portable welding machine

-

MAG TIG MIG welding machine 220V 161A 3 in 1 economic portable ZELDA

-

MIG MIG MIG 3 in 1 multifunction 230V MIG MIG welding machine

-

high quality mig wire feeder

-

TIG Gas Lens Chuck Body Fits SR WP 17 18 26 TIG Welding Guns