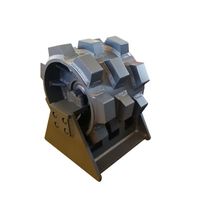

High Quality Crusher Bucket For Excavator Heavy Machine Construction Machinery Parts

-

Supplier: Shandong Mingde Gangcheng Machinery Co., Ltd. -

Region: Shandong, China -

Contact: Mr Jack Hua -

Price: $1000.00 /piece -

Min. Order: 1 piece

Product details

| Material: | Q345B+NM400+hard up+WH60 | high: | custom made |

| Warranty: | 1 year | Origin: | Shandong Province, China |

| product name: | Crusher bucket | Health status: | new |

| Marketing Type: | Hot Products of 2023 | width: | customized, customized |

| Applicable industries: | Mechanical repair shops, manufacturing plants, energy and mining, retail, building materials stores, construction | finger: | 4,5,6,7 or customized |

| Applicable excavator (ton): | custom made | model: | custom made |

| payment terms: | L/C, T/T | Core components: | bearing |

| Video outbound inspection: | if | weight: | 3000kg, 3000kg |

| application: | broken rock | Packaging Details: | simple pallet or case |

| brand: | world trade organization | color: | orange |

| Applicable excavator: | 6-90 tons | port: | Qingdao/Shanghai |

| length: | customized, customized | Supply capacity: | 500 pieces per month |

| Mechanical test report: | if | MOQ: | 1 set |

| Showroom location: | Australia |

Product Description

The crusher bucket is usually installed on the excavator, using the hydraulic power of the excavator, relying on the strong clamping force of the upper and lower jaws to crush stones, it can crush stones and construction waste, and can quickly separate steel bars. Concrete, which reduces the handling of concrete blocks on the project site. The transportation and other engineering costs associated with the crushed stone prompted the concrete waste to be recycled and reused directly on the construction site.

Model | PSD-70 | PSD-120 | PSD-200 | PSD-300 | PSD-670 | PSD-870 |

Excavator weight (t) | 6-10 | 10-18 days | 18-30 days | 30-45 | 50-70 | 75-90 |

Bucket capacity (m3) | 0.2 | 0.45 | 0.74 | 1.15 | 1.47 | 2.23 |

Oil flow (l/min) | 40-45 | 80-100 | 180-200 | 260-280 | 340-360 | 440-460 |

Feed size (mm) | 400*330 | 400*550 | 500*700 | 500*1000 | 670*1150 | 670*1316 |

Machine size(mm) | 1630*1013*1150 | 1950*1120*1500 | 2506*1325*1730 | 2346*1576*1665 | 28822105*2137 | 28822271*2137 |

Machine weight (kg) | 880 | 1360 | 3450 | 4220 | 6850 | 7668 |

Product Details

We adopt a direct drive system to make maintenance easier.

2. Work efficiently

The optimized design of the jaw plate has higher crushing efficiency. Save fuel consumption by minimizing the operating system.Replaceable upper and lower jaws.

3. HARDOX steel

The welded structure is made of HARDOX steel. Light weight, higher strength.Application field

"The only thing that outlasts our products,is our commitment to customer service and satisfaction”

Our advantage

1. One machine with multiple functions, especially suitable for crushing and recycling of building concrete and mountain road construction, with good flexibility and cost advantages. 2. Adopt advanced hydraulic technology, use hydraulic motor to drive the jaw plate to rotate, crush concrete, stone, etc., to meet the set requirements. 3. The waste material is discharged from the discharge port, and the steel bars smaller than the discharge port can also be discharged from the discharge port at the same time.

VIEW MORE

You may like

-

Excavator rake bucket Root rake bucket suitable for 8 ton construction excavator Kubota KX080

-

Small excavator construction machinery accessories root rake

-

D85 Bulldozer Farm Use Root Harrow For Sale Use Hardox 700 Steel + NM400

-

Factory Price Brand New Land Clearing Excavator Stick Rake Excavator For 1-50 Ton Q345/NM400 ZX210 Excavator

-

Weixiang Best Selling Excavator Root Rake Ship Engineering Construction Excavator Hot Selling

-

HONGWING Attractive Price Mini Excavator Mechanical Rake Rake Excavator Rake Bucket Rake

-

Wholesale gardening rake hoe gardening plastic hand leaf rake excavator rake

-

Hydraulic rake grab for skid steer loader root rake

-

OEM factory supply rake attachment for mini excavator

-

High Quality OEM Skid Loader Planer

Other Products

-

$4500.00 - $5500.00 / set

$4500.00 - $5500.00 / set -

$700.00 / set

$700.00 / set -

$100.00 / piece

$100.00 / piece

Related Search

high qualiti fishey len for iphon 4 suppliers

high qualiti pocket bike for sale suppliers

1 high qualiti usb cabl for iphon suppliers

high quality toilet soap machine

high quality edge banding machine edge bander

high quality tea plucking machine

bucket for hitachi zx330 excavator

high quality vacuum aluminium coating machine

high quality charcoal powder extruding machine

high quality led screen board for advertising