Tire Shredder Equipment Rubber Tire Shredder Recycling Machine Double Shaft Shredder

-

Supplier: Wuxi Dura-Shred Recycling Technologies Co., Ltd. -

Region: Jiangsu province, China -

Contact: Mr Manfred Dong -

Price: $10000.00 /unit -

Min. Order: 1 unit

| ensure: | 3 years | Dimensions (L*W*H): | 2835*2624*3040 |

| Core component warranty: | 1 year | Video outbound inspection: | if |

| Marketing Type: | New Products for 2021 | Voltage: | 380V |

| experience: | More than 10 years of professional experience | Origin: | Jiangsu, China |

| product: | Rubber crumbs (2-6mm) | Processing tires: | Passenger Car/Truck/Construction Machinery/Agricultural Vehicle Tires |

| type: | tire machine | Mechanical test report: | if |

| Warranty: | over 5 years | Name: | Dura-shred customized waste tire shredder and spare parts |

| Production capacity: | 5-10t/h(according to request) | environment: | environment friendly |

| Type of tire machine: | tire recycling machine | Serve: | Best pre-sales and after-sales service |

| brand: | dora shredded | Showroom location: | Morocco, Kazakhstan, USA, Mexico, Spain |

| model: | TSD2471-A502 | Supply capacity: | 1 Dura-shred customized waste tire shredder and spare parts per month |

| Core components: | PLC, bearings, gearboxes, motors | Main selling points: | automatic |

| Weight (kg): | 23000 kg | control: | Siemens PLC |

| Applicable industries: | Building Materials Stores, Manufacturing Plants, Machinery Repair Shops, Retail, Construction Engineering, Energy and Mining, Other | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

| Health status: | new | Power (kW): | 55*2kw |

hot sale! ! ! Dura-shred customized waste tire shredder and shredder spare parts

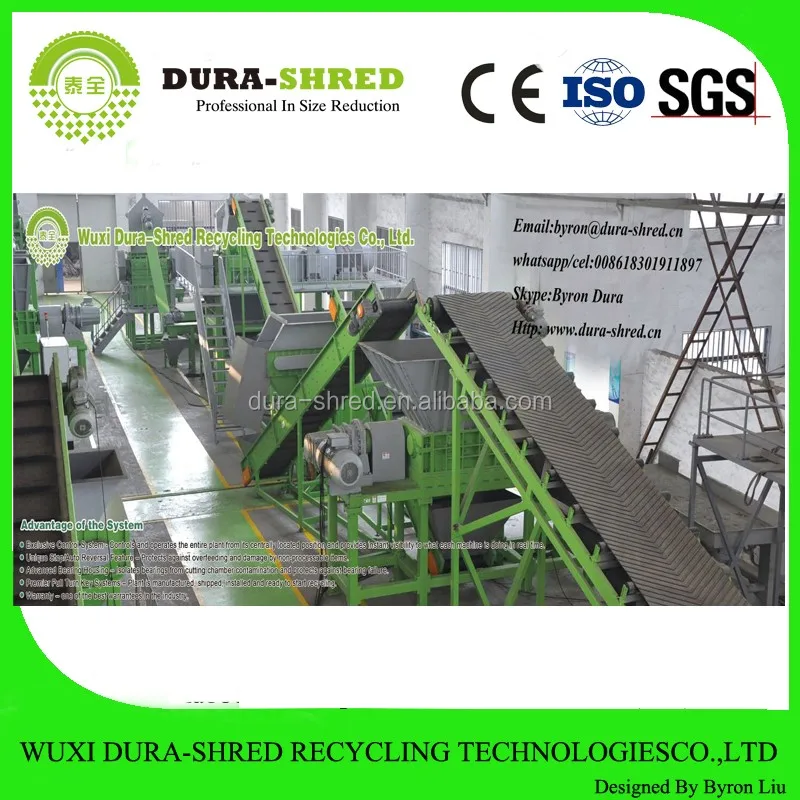

Dura-shred's twin shaft shredders are designed with advanced low speed, high torque shredding technology. Each axle is driven by its own Siemens motor, providing plenty of power to drive the tires and thick steel balls. Shredder blade thickness ranges from 25mm to 152mm (1”-6”) depending on tire type, throughput and desired end product. The shredder can process OTR, truck and car tires at speeds up to 20 tons per hour.

Dura shredding uses high-quality steel from China's largest steel plant (Baosteel, Wuhan Iron and Steel, Dongbei Special Steel, Xincheng Special Steel, etc.) and uses various high-standard special steels to manufacture our products, such as: 42CrMo, Cr12Mo1V1

All materials have the original factory quality certificate

We choose Siemens motor as our standard configuration. For the remaining spare parts, we will provide two different brands for customers to choose---Gearbox: Boneng/SEW Bearing: SEW/ZWZ.

In order to facilitate the maintenance work, we specially designed the shredder, file, and pelletizer platform, which is safe and convenient.

As for the paint, we use JOTUN brand paint. Also, we paint three times before delivery. The regular color of our machine is green. We believe this is the color of the environment. We will also draw colors according to our different requirements, such as: blue, gray...etc.

Generally speaking, waste tires have the following uses:

1.Energy Recovery and Civil Engineering. At this stage, people cut the tire into small pieces (about 40 cm to 120 cm) to make tire oil, also known as tire loosening. We call this stage TDF factory-- the tires are what we shedDouble Shaft Shredderand transform into the desired sizeDisk classifier.

2.used forGarden Decoration and Playground Protection. In this stage one will cut the shredded tires (after the first stage) into smallerRubber covering (about 15-35cm), at this stage the tire wires can unravel. We call this stagerubber covered plants--The tires are shredded smaller by usgrater( Also known asRaspa) and steel bymagnet.

3. Applied to runways, playgrounds and making rubber mats. At this stage, one cuts the rubber mulch into rubber granules (1-8 mm or so), at this stage the fibers can be separated. We call this stageasrubber crumb plant--The tires are shredded smaller by usGranulatorand fibers are separatedfiber removal system.

4. Application in construction and road construction. At this stage, people grind the rubber particles to 40-120 mesh rubber powder. We call this stagerubber powder factory--The tires were torn to powder by usmiller.

Our products have been sold all over the world, including the United States (our main customer), Italy, Poland, Hungary, Enida, Turkey, Japan...etc. No matter where you are from, Dura-shred is looking forward to cooperating with you!

Packaging and Shipping:

When packing, we use wooden pallets to load the shredders and files so that they can be easily secured into the shipping container. We will use wooden boxes to load blades, motors and other spare parts to prevent collisions during delivery.

Professional factory!

Our production plant is located in Wuxi, China and our headquarter is located in Shanghai, China. We have a modern factory and experienced and professional workforce. Our management team is made up of multicultural and bilingual professionals, fluent in English, Spanish and Mandarin.

Maintenance service:

We will provide a 1 year warranty on our blades, motors, gearboxes, bearings and a 20 year warranty on our factory frames. We recommend that customers conduct "bolt tightening, lubrication and normal inspection" on the whole shredder, shredder and granulator for about one and a half hours. We can also send engineers to your factory to help you with maintenance work if needed. Below are the photos we took while we were doing maintenance work for our customers in India.

Our advantage:

As one of the leading companies in the recycling industry, we have been manufacturing recycling machinery with more than 10 years of experience. Our machinery has been exported all over the world. As a professional team, we also have an American company in the United States to handle our pre-sales and after-sales services, and have a research and development department in the United States, all our technologies come from the United States and Europe, and all the machines we design and produce are energy-saving , low noise, automation at room temperature, the best quality assurance, and equipped with the best equipment such as Siemens motors and FAG bearings. We are very professional.Choose Dura to shred, choose success!

-

OEM double shaft tire shredder price shredder

-

hot sale tel shredder rubber tire twin shaft shredder

-

Industrial Recycler Plastic Wood Pallet Shredder Tire Cutter Dual Shaft Wood Shredder

-

Heavy Duty Industrial Scrap Car Tire Shredder for Scrap Tire Shredder

-

Full automatic customizable waste tire shredding recycling machine / tyre shredder

-

waste tire recycling machine tire/tyre shredder machine price in China

-

recycling tyre machine tire cusher and tyre shredder

-

Full Automatic Whole Tire Shredder Machine Made in Qingdao Eenor Rubber Machinery Co.,Ltd

-

Used Tyre Grinding Cutting Machine Rubber Tire Crusher

-

large tyre shredding machine price waste tyre shredder for sale