Waste-to-energy power plants Municipal solid waste Household waste Hospital waste large-scale incinerators

-

Supplier: Shandong Kangtailong Intelligent Equipment Co., Ltd. -

Region: Shandong, China -

Contact: Ms Nancy Zheng -

Price: $60000.00 /set -

Min. Order: 1 set

Product details

| Supply capacity: | 1 set per month | Origin: | Shandong Province, China |

| application: | family, hospital | Video outbound inspection: | if |

| Health status: | new | Weight (kg): | 30000 kg |

| fuel: | diesel engine | Marketing Type: | New Products for 2022 |

| Production capacity: | 1-5000 tons/day | Core components: | PLC, combustion system, flue gas treatment system, online monitoring system |

| Core component warranty: | 1 year | Finished goods: | ashes |

| type: | Large domestic waste incinerator | Applicable industries: | Hotels, clothing stores, building supplies stores, manufacturing plants, machinery repair shops, food and beverage factories, farms, restaurants, household, retail, food stores, print shops, construction, energy and mining, food and beverage stores, advertising agencies |

| model: | KTL-20 | Advantage: | Suitable for large families and hospital waste disposal |

| Material: | container shipping | port: | Qingdao Port |

| payment terms: | L/C, T/T | Package preview: | |

| Mechanical test report: | if | Showroom location: | not any |

| Voltage: | 380V/220V | Packaging Details: | According to customer requirements |

| size: | need a big factory | Warranty: | 1 year |

| strength: | 25 | raw material: | Carbon steel anti-corrosion and refractory adhesive |

| Certification: | CE | Function: | Combustion, power generation |

| Name: | Large-scale urban life hospital waste incinerator | brand: | Ktar |

Household waste incineration for power generation

Product Description

1. Small footprint. 2. Low investment cost and high degree of automation. 3. Low operating cost, no need for waste sorting. 4. Waste heat recovery (power generation or heating). 5. There is no need to add any combustion fuel when burning domestic garbage. It can be mixed with aging garbage, sludge, and a small amount of kitchen waste. 6. Garbage filtrate does not need to be treated or incinerated. 7. Fengte gas treatment complies with the current national emission standards (GB18485-2014). 8. The incinerator is unique for 7 consecutive days (168 hours). Be able to respond to emergencies. 9. The slag can be used and can be made into more than ten kinds of outdoor building materials such as hollow bricks and sidewalk bricks. Furnace with zero emissions.

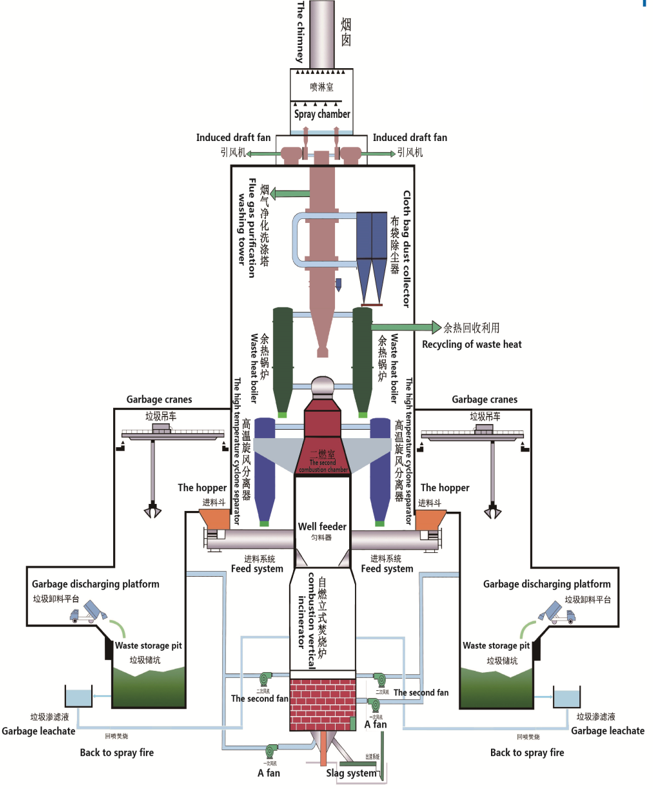

work process

Through the spiral feeding device, domestic waste is continuously and evenly fed into the incinerator from the multi-point directional refinement device in the center of the incinerator. The garbage in the incinerator is fully burned according to the self-heating value of the garbage under the action of the combustion-supporting air sent from the bottom of the incinerator. The furnace temperature is controlled above 850°C, and the flue gas residence time is above 4 seconds. The flue gas dust descends through the high-temperature separator, and after being cooled by the waste heat boiler, it enters the second-stage cyclone separation system, and is treated by the chimney standard discharge system after special adsorbent injection, bag dust collector, and waste smoke purification. The chimney sprinkler water curtain is added to the system to ensure the normal operation of the project and the smoke-free effect of the chimney, and to avoid the chimney's adverse impact on the citizens. The coal slag after waste incineration can be used as building materials, and the heat energy generated by incineration can be recovered and utilized through the waste heat boiler. The whole system is completed by the central control room to achieve the harmless, reduction and automatic recycling of garbage.

Steam power generation, brick making, heating

1. The power generation can be generated for self-use, and the electricity can be connected to the grid; 2. The system is automatically protected and operated without personnel; 3. The generator set is small in size and occupies a small area; 4. Different units do not affect the operation of other generator sets; 5. The structure of the generator set is simple , high operating stability; 6 use of power generation, safety and environmental protection.

Thorn brick

provide heating

transportation

customer photo

VIEW MORE

You may like

-

Truck recycling container glove box garbage container large dumpster

-

Domestic Digester Plant

-

PE Underground Septic Tank 600L -2500L

-

20 yard Tube Roll Container

-

Cable copper wire recycling machine/copper wire recycling machine cable granulator for sale

-

High German Supplier Hydraulic Recycling Scrap Metal Compactor

-

Automatic classification line of municipal solid waste recycling plants

-

Sludge waste incinerator boiler pollution control smokeless medical waste incineration boiler manufacturer

-

Three-way catalytic cutting machine

-

Roll-on roll-on containers